Single-diversion-tunnel water-power engineering hoist arrangement structure

A technology for water diversion tunnels and hydropower projects, which is applied in water conservancy projects, hydroelectric power generation, hydropower stations, etc. It can solve the problems of increasing investment, increasing the amount of excavation and concrete pouring, and achieves the effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

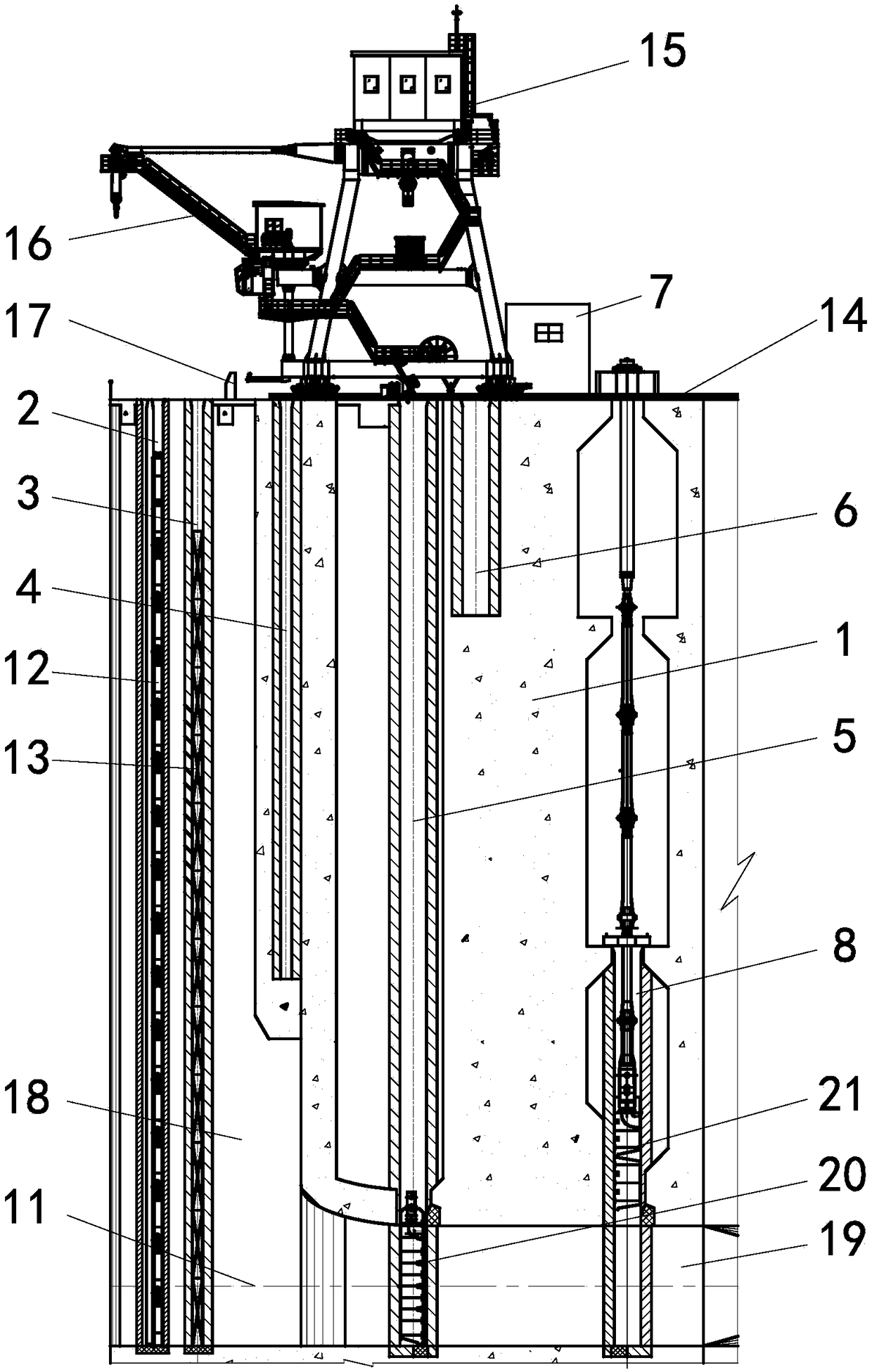

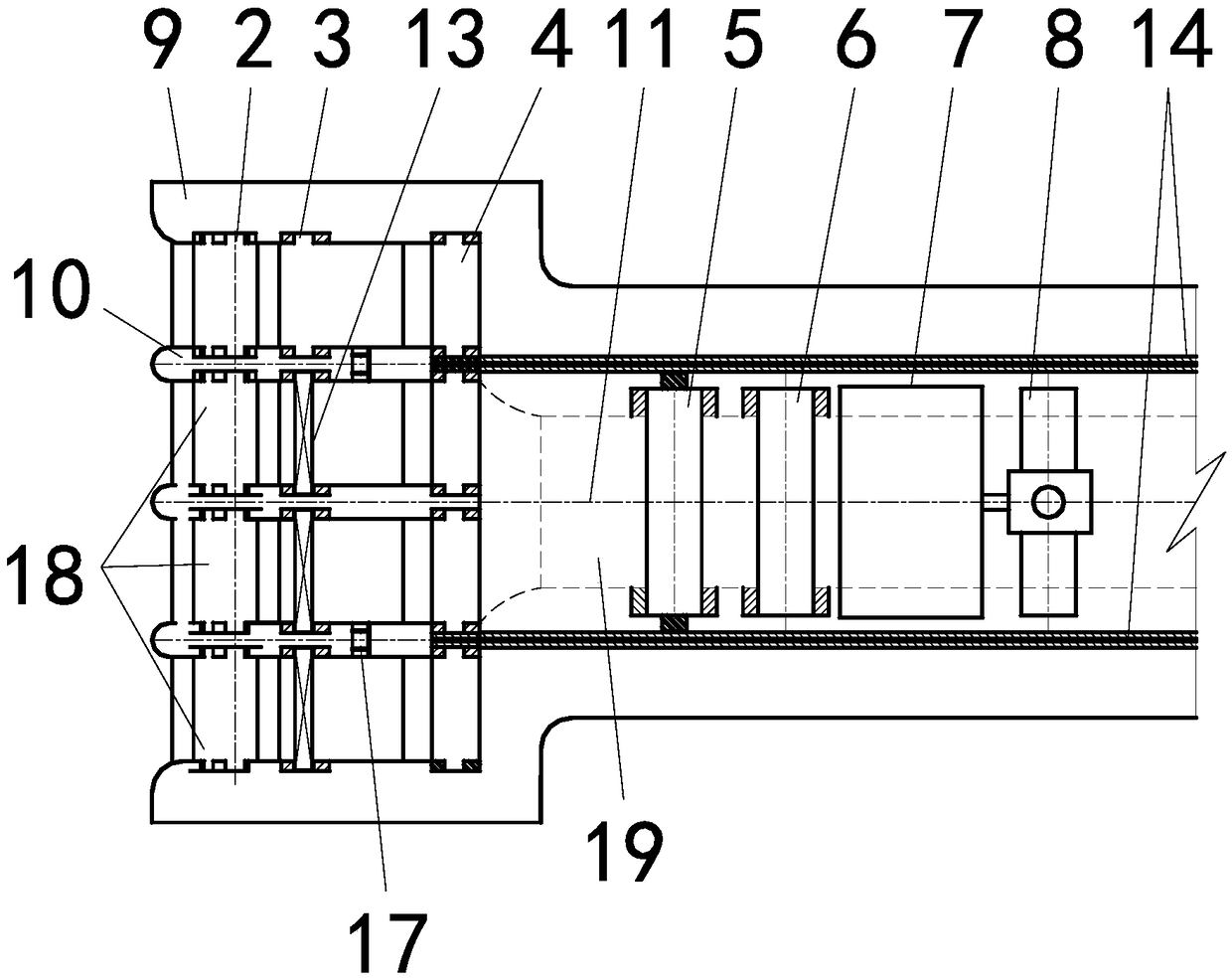

[0018] In this example, the trash rack slot 2, layered water intake stack beam door slot 3, layered water intake stack beam door storage 4, maintenance gate slot 5, maintenance gate storage 6, and hydraulic pump room 7 are sequentially arranged at the water inlet of the dam body 1 along the water flow direction And fast gate slot 8. The front section of the single diversion tunnel is divided into multiple flow channels 18 by two side piers 9 and more than one middle pier 10 ; the rear section of the single diversion tunnel is a single flow channel 19 .

[0019] Each flow channel of the multi-runner 18 is provided with a trash rack slot 2; a trash rack 12 is arranged in each trash rack slot 2; a layered water intake stack is arranged behind each trash rack slot 2 Beam door slot 3; each layered water intake stack door slot 3 is provided with a layered water intake stack door 13; each layered water intake stack door slot 3 is equipped with a layered water intake stack door storeh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com