Compact type oil cylinder hydraulic driving system

A drive system, compact technology, applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, servo motors, etc., can solve the problems of occupying a lot of space, large structure of hydraulic station, not suitable for small installation space, etc. Compact structure, small size, to achieve the effect of function expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further elaborated below by specific embodiment:

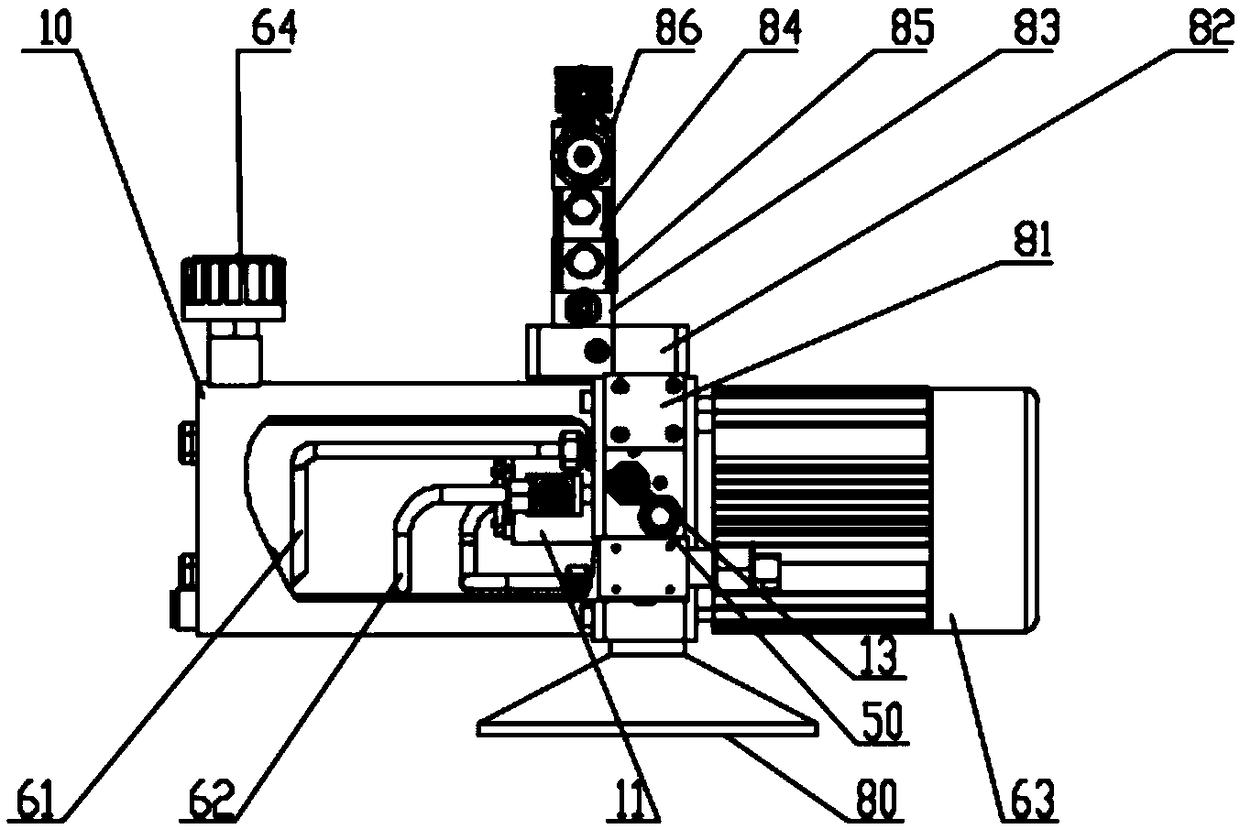

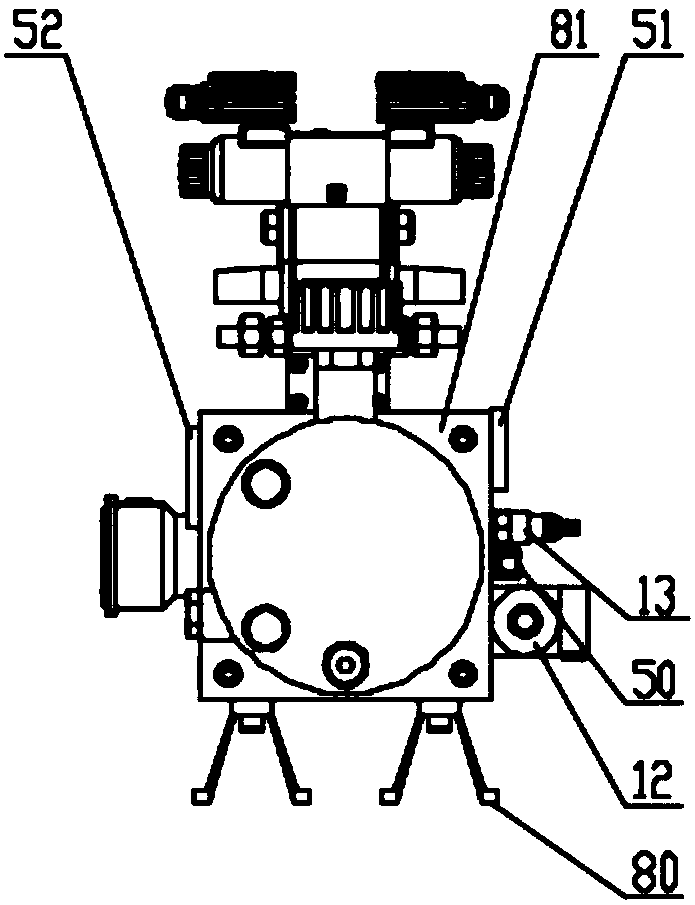

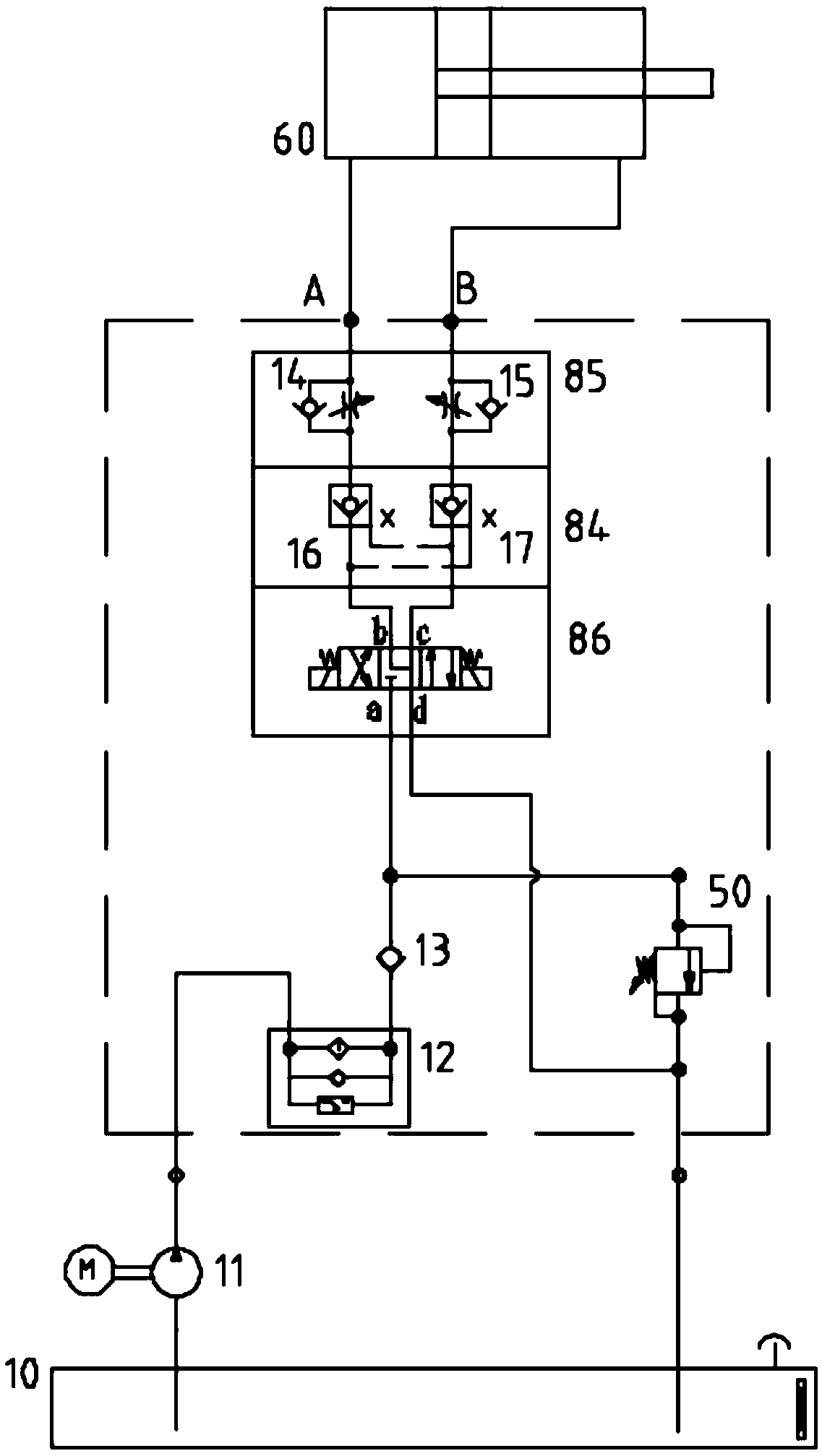

[0019] Such as figure 1 and figure 2 shown (for convenience, refer to figure 1 direction shown), the compact oil cylinder hydraulic drive system of the present invention includes a base 80, a fuel tank 10, a main valve block 81, a transition connection block 82, an AB oil port valve block 83, a two-way hydraulic lock 84, and a one-way throttle valve group 85. Proportional reversing valve 86.

[0020] Wherein, the main valve block 81 is installed on the base 80 . The left surface of main valve block 81 is fixed with submerged oil pump 11, oil return pipe 61, oil tank 10 and oil suction pipe 62. The oil inlet of the submerged oil pump 11 communicates with the oil suction pipe 62 through the flow channel in the main valve block. A motor 63 for driving the submerged oil pump 11 is fixed on the right surface of the main valve block 81 . An air filter 64 is also installed on the top of the fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com