Headlamp dimming support structure

A bracket structure, headlight technology, applied in the direction of headlights, optical signals, lighting devices, etc., can solve the problems of gaps and scratches between the manual dimming screw 9 and the guide rail sleeve 8, so as to avoid scratching defects, Shake reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

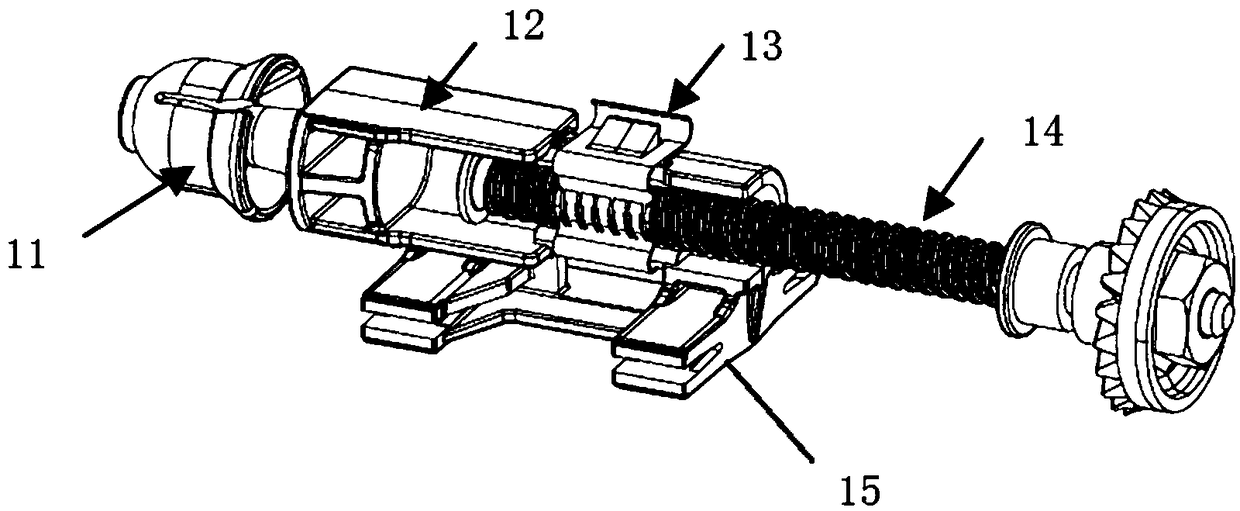

[0017] Such as image 3 -4, a headlight dimming bracket structure, including a manual dimming assembly, the manual dimming assembly includes a manual dimming guide rail 15, a universal seat 11, a guide rail sleeve 12, a metal card 13 and a manual dimming Light screw 14, the guide rail sleeve 12 is connected with the manual dimming guide rail 15, the guide rail sleeve 12 and the manual dimming guide rail 15 are preferably an integral injection molding part, the guide rail sleeve 12 and the universal The seat 11 is connected, the guide rail sleeve 12 is threadedly connected with the manual dimming screw 14, and the metal card 13 is respectively connected with the guide rail sleeve 12 and the manual dimming screw 14.

[0018] Such as image 3 As shown in -4, the metal card 13 is threadedly matched with the manual dimming screw 14 .

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com