Test device and test method for horizontal stress of compacted soil

A technology of horizontal stress and test device, applied in the direction of measuring device, force/torque/work measuring instrument, instrument, etc., can solve the problems of large test error, low precision, matching error, etc., to achieve small test error, high precision, weakening effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

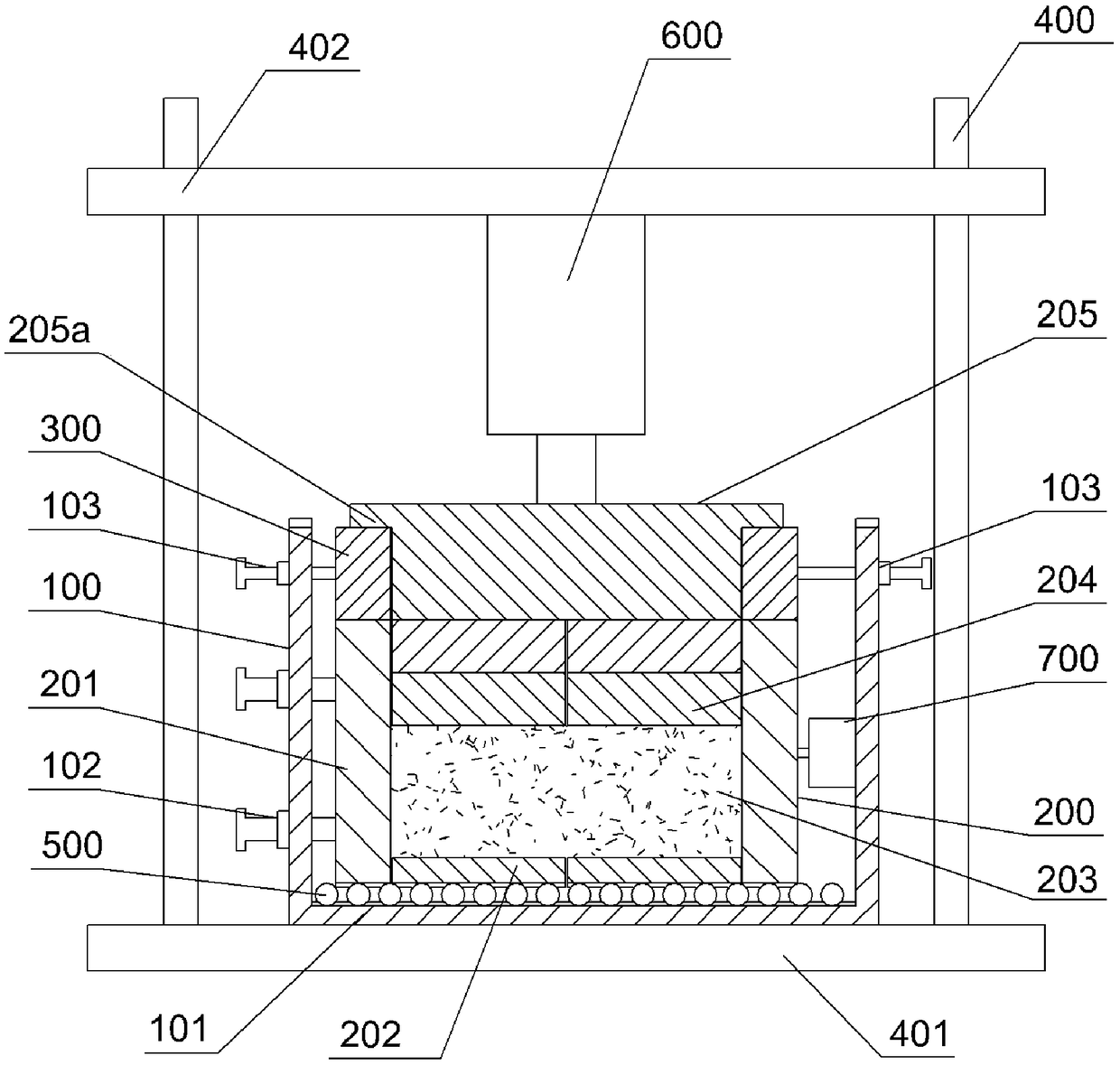

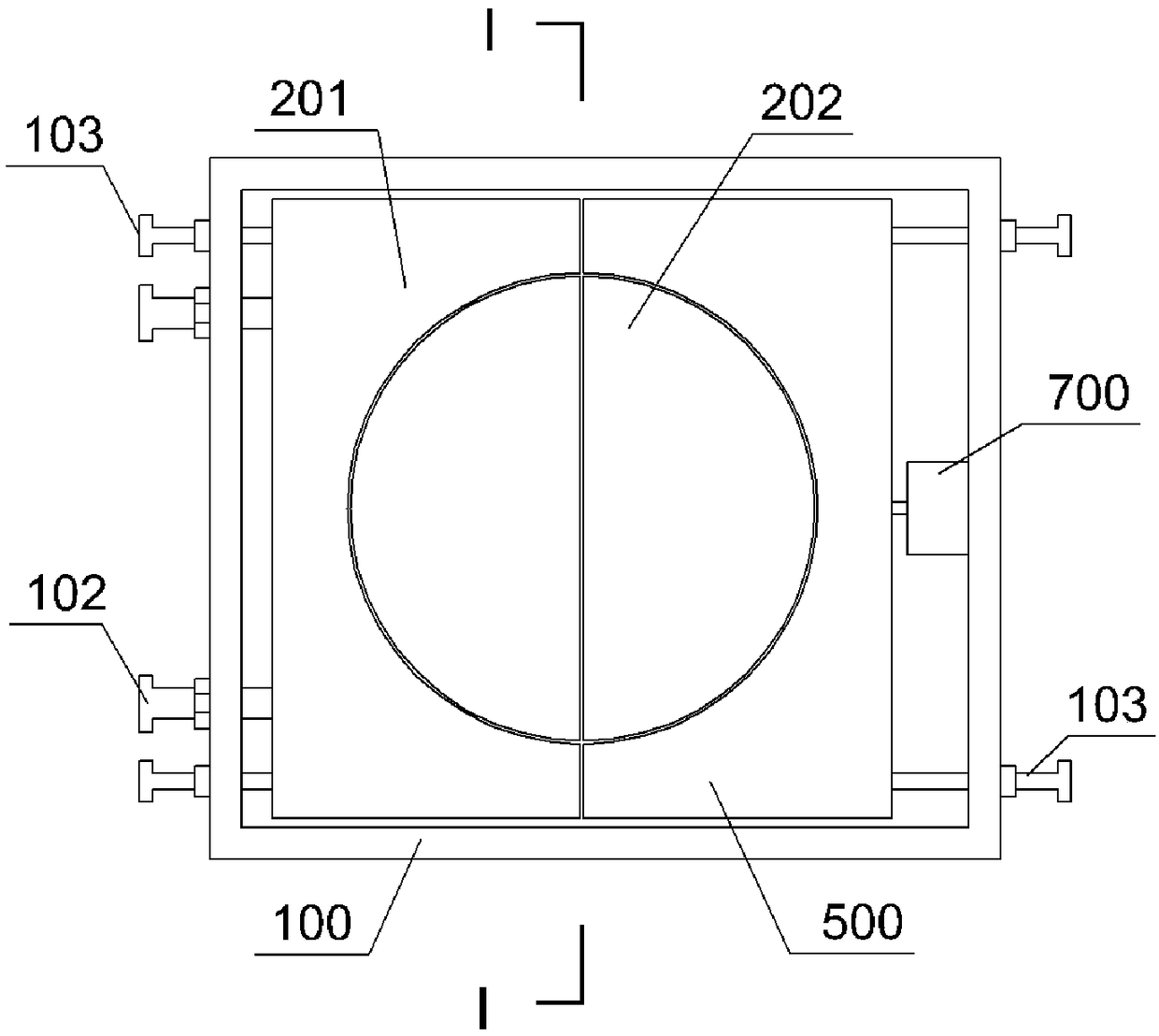

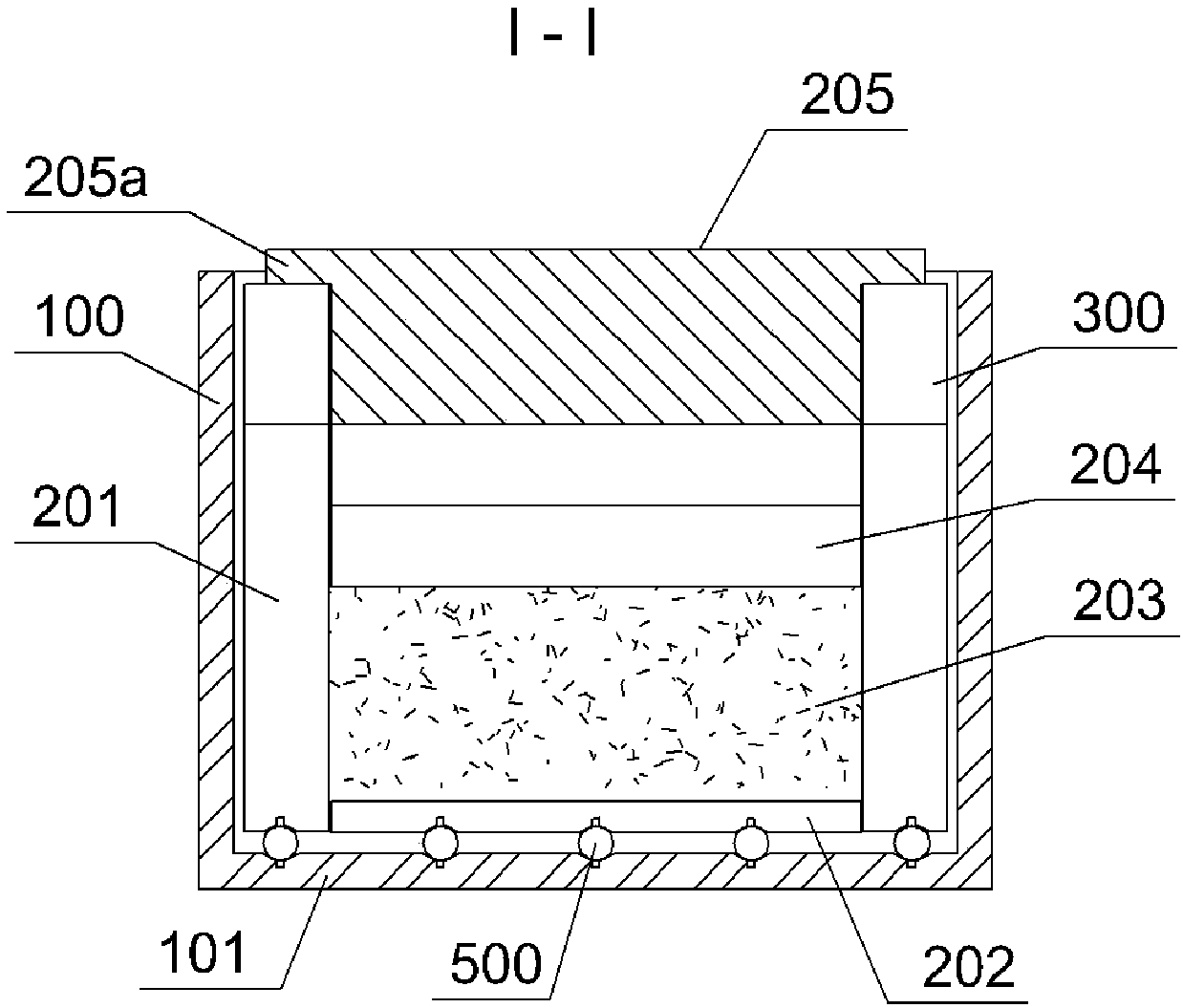

[0030] Figure 1~3 Shown, a kind of embodiment of the present invention is, a kind of compacted soil horizontal stress testing device, its composition is:

[0031] The rigid and rectangular limit box 100 with the upper part open is placed on the bottom plate 401 of the reaction rigid frame 400; the left and right half cylinders 201 constitute the sample cylinder 200 with an inner circle and an outer square, and the sample cylinder 200 is located at the limit position. inside the box 100, and the outer wall of the sample cylinder 200 is not in contact with the inner wall of the limit box 100; the bottom of the inner cavity of the half-tube 201 is provided with a semicircular half backing plate 202; The bottom of the backing plate 202 and the sample cylinder 200 is provided with an upper chute matching the chute, and a ball 500 is placed between the upper chute and the chute; the top of the half cylinder 201 is provided with a half casing 300, and the left and right two Two hal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com