An internal defect detection method for a multilayer metal lattice structure material based on Faster R-CNN

A lattice-structured, multi-layered metal technology for analyzing materials, material analysis using wave/particle radiation, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The specific embodiments described here are only used to explain the present invention, not to limit the invention.

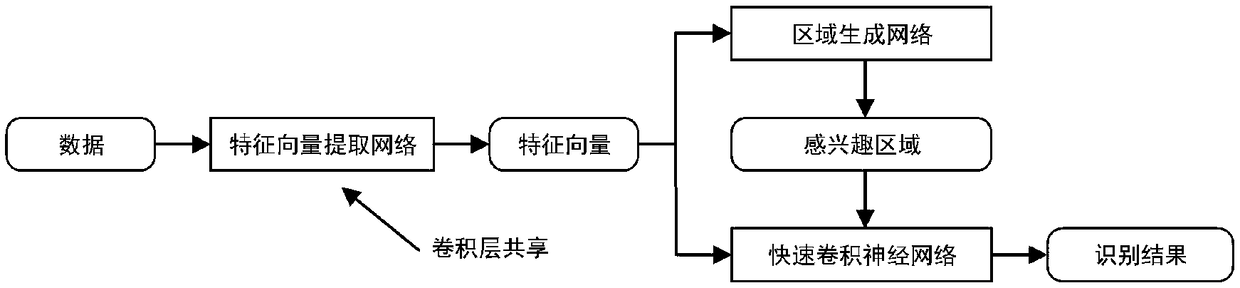

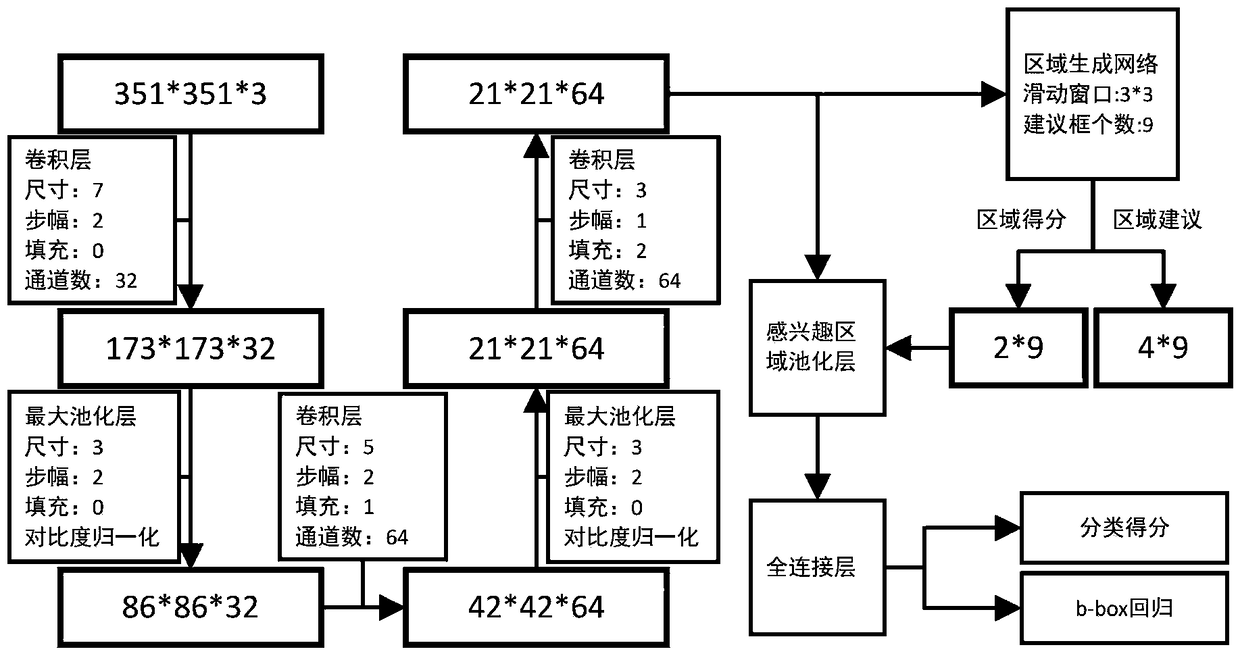

[0022] A method for detecting internal defects of a multilayer metal lattice structure material based on Faster R-CNN of the present embodiment comprises the following steps:

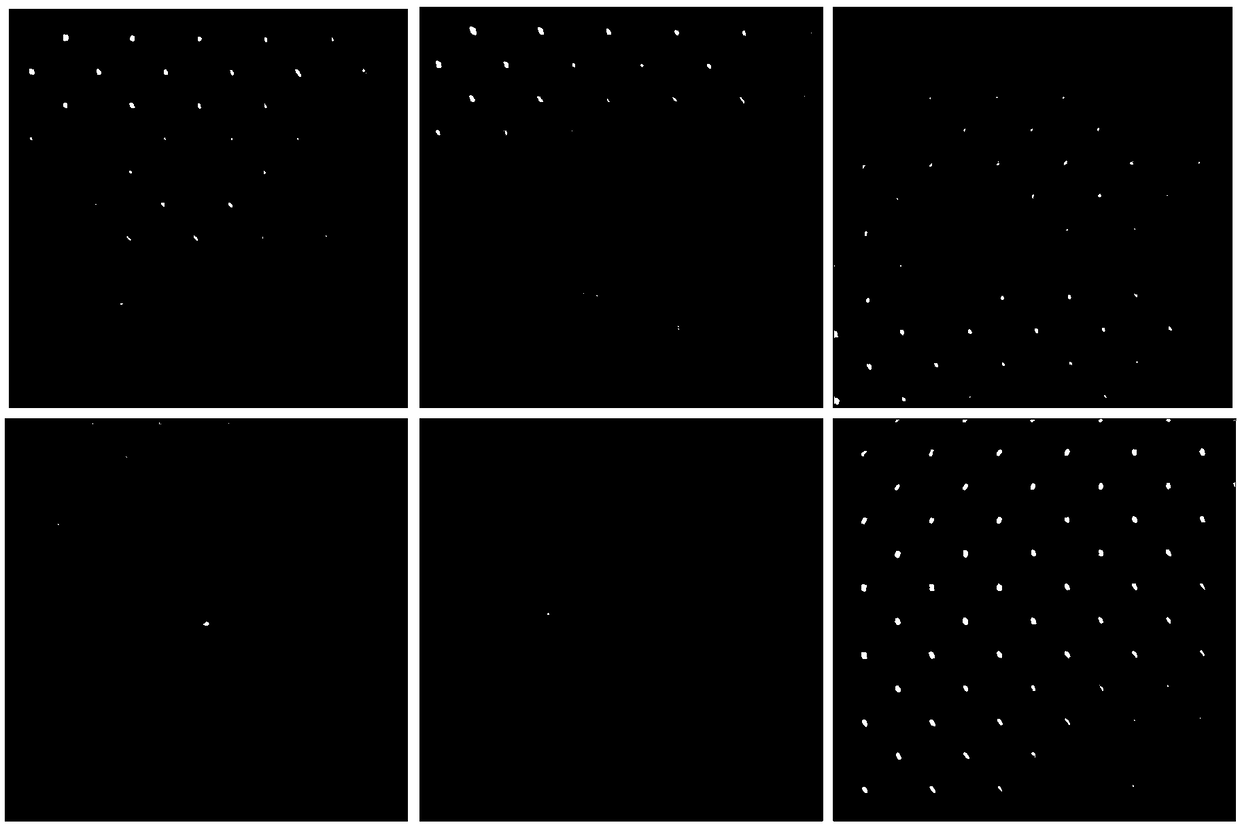

[0023] Step1. The Ti-6Al-4V titanium alloy multilayer metal lattice structure prepared by additive manufacturing technology is used as the sample to be tested. The sample is scanned by industrial CT to obtain the three-dimensional structure inside the sample. From the obtained three-dimensional 124 cross-sectional views of samples were taken equidistantly from the bottom to the top of the effective area in the vertical direction of the structure. The effective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com