Metal lattice interlayer plate with embedded defects and mechanical property detection method thereof

A metal lattice, prefabricated defect technology, applied in the direction of using stable tension/pressure to test material strength, measuring device, strength characteristics, etc., can solve the problems of high preparation cost, unfavorable promotion and application, complex preparation process and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

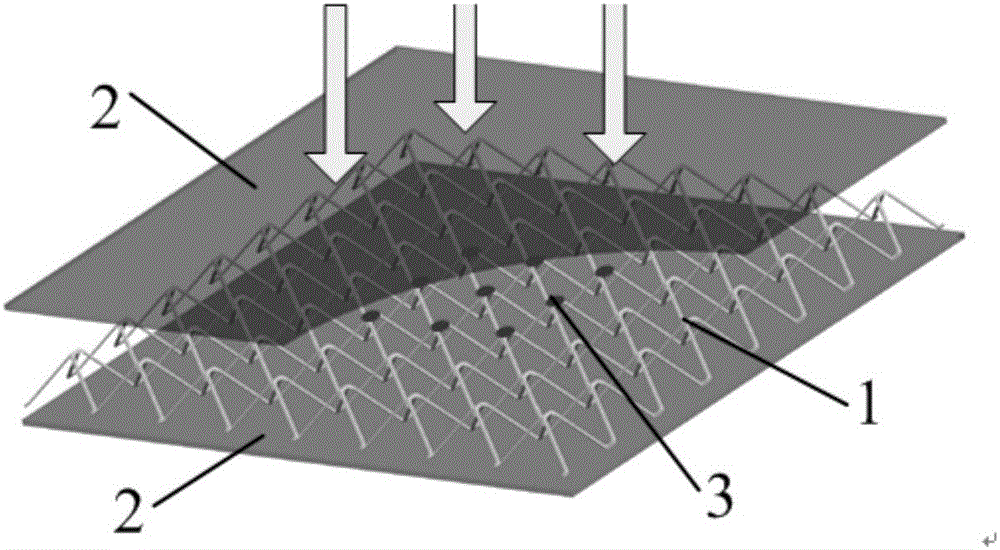

Method used

Image

Examples

experiment example 1

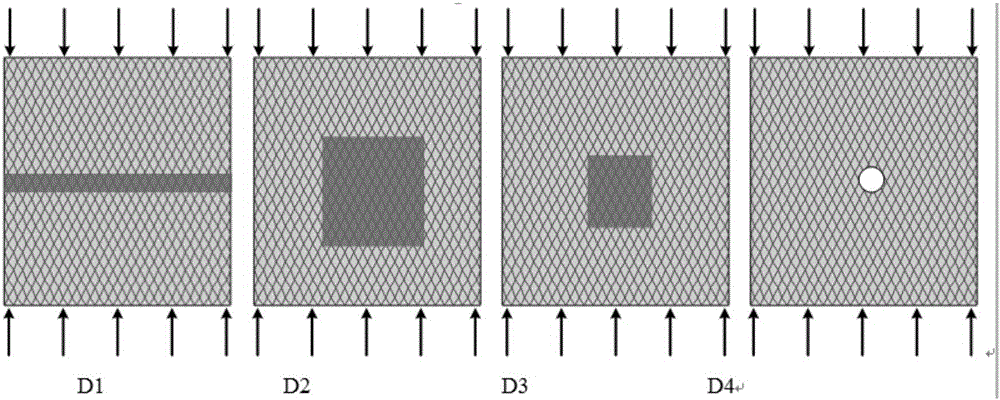

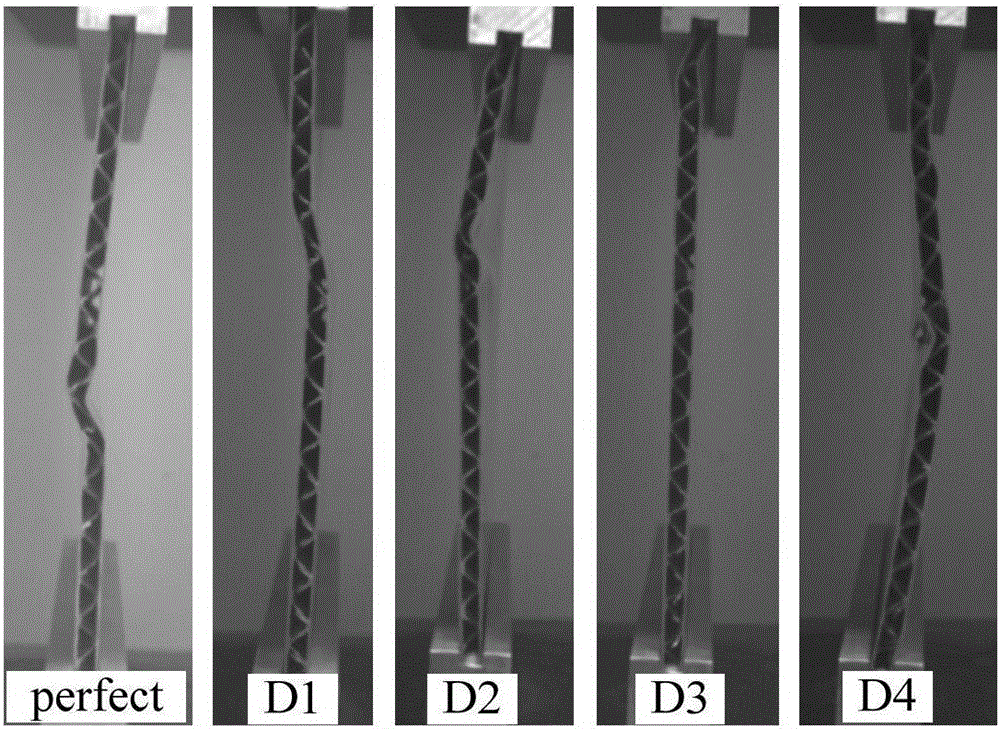

[0035] The mechanical properties of the above four metal lattice sandwich panels with welding defects and panel perforation defects were tested respectively, and the dimensions of the four sample panels were all 250×250×7.8mm. They are:

[0036] D1. Single row lack of soldering, D2. The center contains 6×11 solder joints missing solder; D3: The center contains 4×7 solder joints missing solder; D4: The panel is perforated. The schematic diagram of the four samples is as follows figure 2 shown.

[0037] A 100-ton hydraulic universal material testing machine of the model WE-1000B is used to conduct compression tests on metal lattice sandwich panels with prefabricated defects. In-plane pressure is applied on both sides of the lattice sandwich panels. The loading form is displacement loading, and the loading rate is 2mm. / min. According to the load read by the material testing machine, the load-displacement curve under the in-plane compression condition can be obtained. At the ...

experiment example 2

[0042] Examination of the effect of defects containing missing cells on the natural frequencies of metal lattice sandwich structures:

[0043] During the excitation process, a three-dimensional laser vibrometer is used to test the natural frequency of the lattice metal sandwich plate structure with cell missing defects, where A00 represents a intact lattice sandwich plate, and SD1 represents a lattice with 2×3 cell missing defects Sandwich plate specimens, SD2 represents lattice sandwich plate specimens with 3×4 cell deletions, SD3 represents lattice sandwich plate specimens with 4×5 cell deletions. The result statistics are shown in Table 1:

[0044] Table 1

[0045]

[0046]

[0047]It can be seen from Table 1 that the absence of cells will have a great influence on the natural frequency of the lattice sandwich structure. When the cell missing rate reaches 1.7%, the first-order natural frequency of the lattice sandwich plate specimen decreases by 15.5%, and when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com