Method of electric arc fuse additive manufacturing of metal lattice structure and product

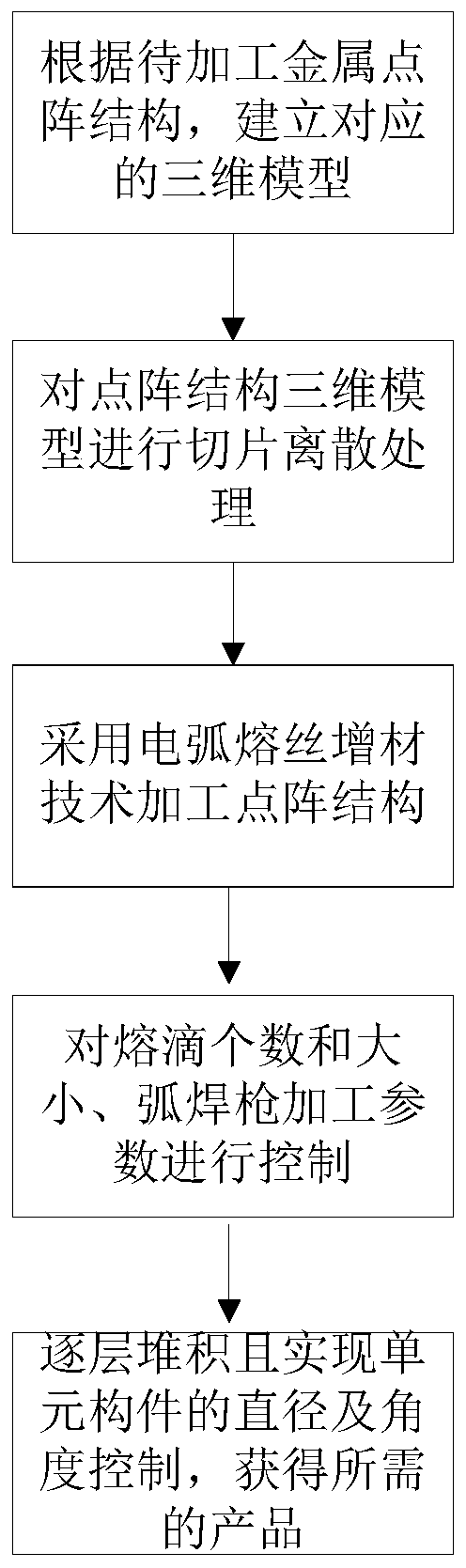

A technology of additive manufacturing and metal lattice, applied in the direction of manufacturing tools, additive processing, arc welding equipment, etc., can solve the problems of metal powder manufacturing difficulties, difficult application, and unformable components, etc., to improve material requirements and processing quality Insufficient aspects, high precision and quality performance, and the effect of an open molding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

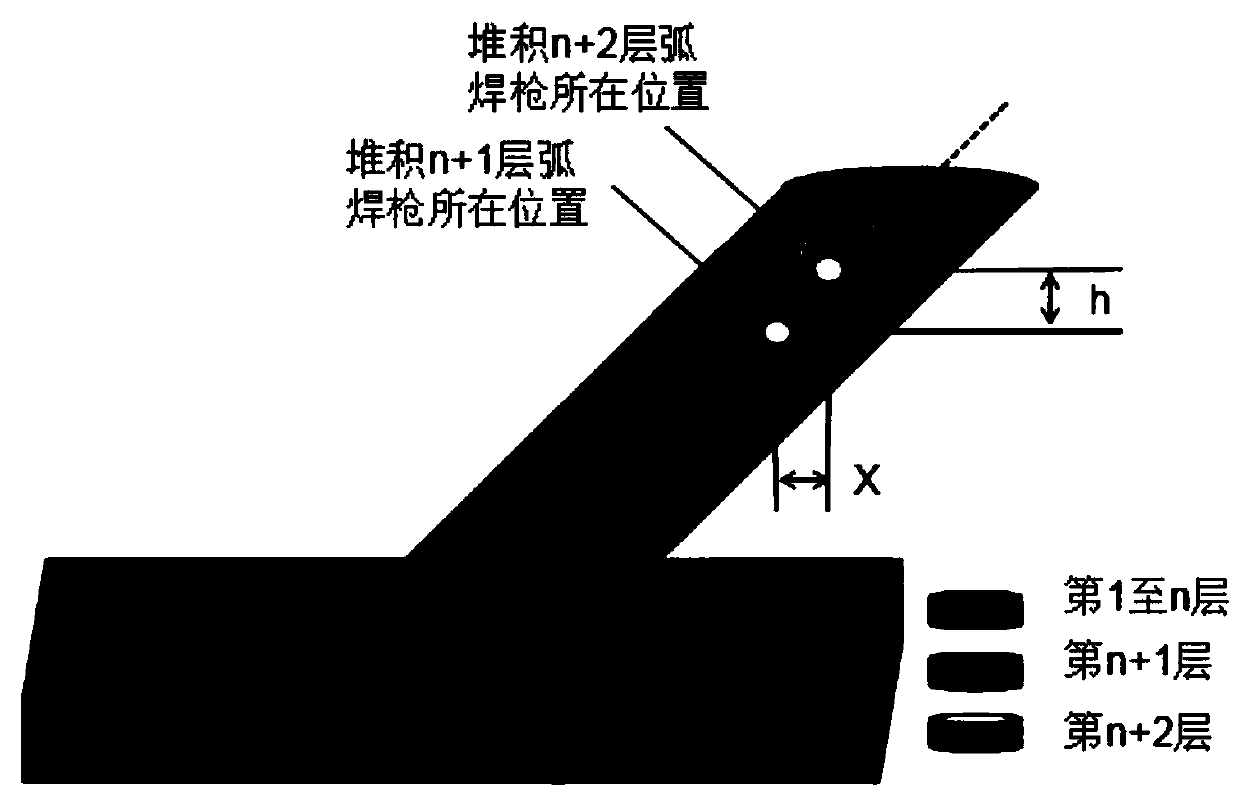

Method used

Image

Examples

Embodiment 1

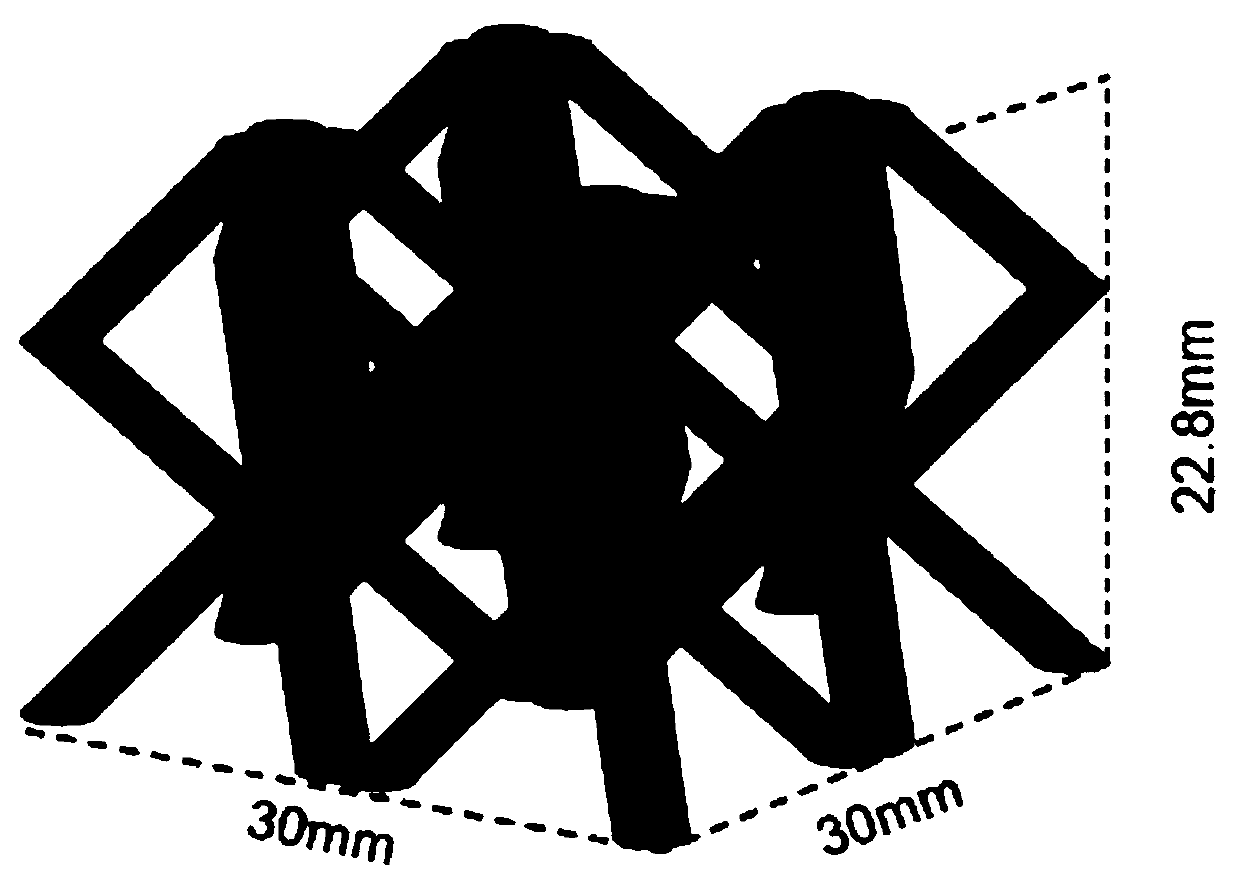

[0043] like image 3 As shown, the X-direction side length of the overall lattice structure is 30 mm, the Y-axis direction side length is 30 mm, and the Z-axis direction height is 22.8 mm. The distribution mode of the lattice structure is "2×2×3", with 2 lattice structure units distributed on the X-axis and Y-axis respectively, and 3 layers of lattice structure units distributed on the Z-axis; a total of It consists of 12 lattice structure units.

[0044] The lattice structure unit is a pyramid structure, the side length of the X direction is 15mm, the side length of the Y axis direction is 15mm, the height of the Z axis direction is 7.6mm, the diameter of the lattice structure unit rod is 3mm, and the angle between the rod and the horizontal plane is uniform. is 45°. UG software can be used to establish the 3D model of the lattice structure unit, and then the established lattice unit model is superimposed through the array according to the “2×2×3” distribution method to for...

Embodiment 2

[0050] like Figure 4 As shown, the X-direction side length of the overall lattice structure is 36 mm, the Y-axis direction side length is 36 mm, and the Z-axis direction height is 30 mm. The distribution mode of the lattice structure is "2×2×2", with 2 lattice structure units distributed in the X-axis and Y-axis respectively, and 2 layers of lattice structure units distributed in the Z-axis; a total of It consists of 8 lattice structure units.

[0051] The X-direction side length of the lattice structure unit is 18mm, the Y-axis direction side length is 18mm, the Z-axis direction height is 15mm, the diameter of the rod of the lattice structure unit is 2mm, the angle between the central rod and the horizontal plane is 90°, and the quadrilateral rod The angle between the parts and the horizontal plane is 30°. UG software can be used to establish the 3D model of the lattice structure unit, and then the established lattice unit model is superimposed through the array according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com