Bearing device for display panel test

A technology of display panel and carrying device, which is applied in the direction of measuring device, optical instrument testing, machine/structural component testing, etc. Inaccurate detection results, high detection efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

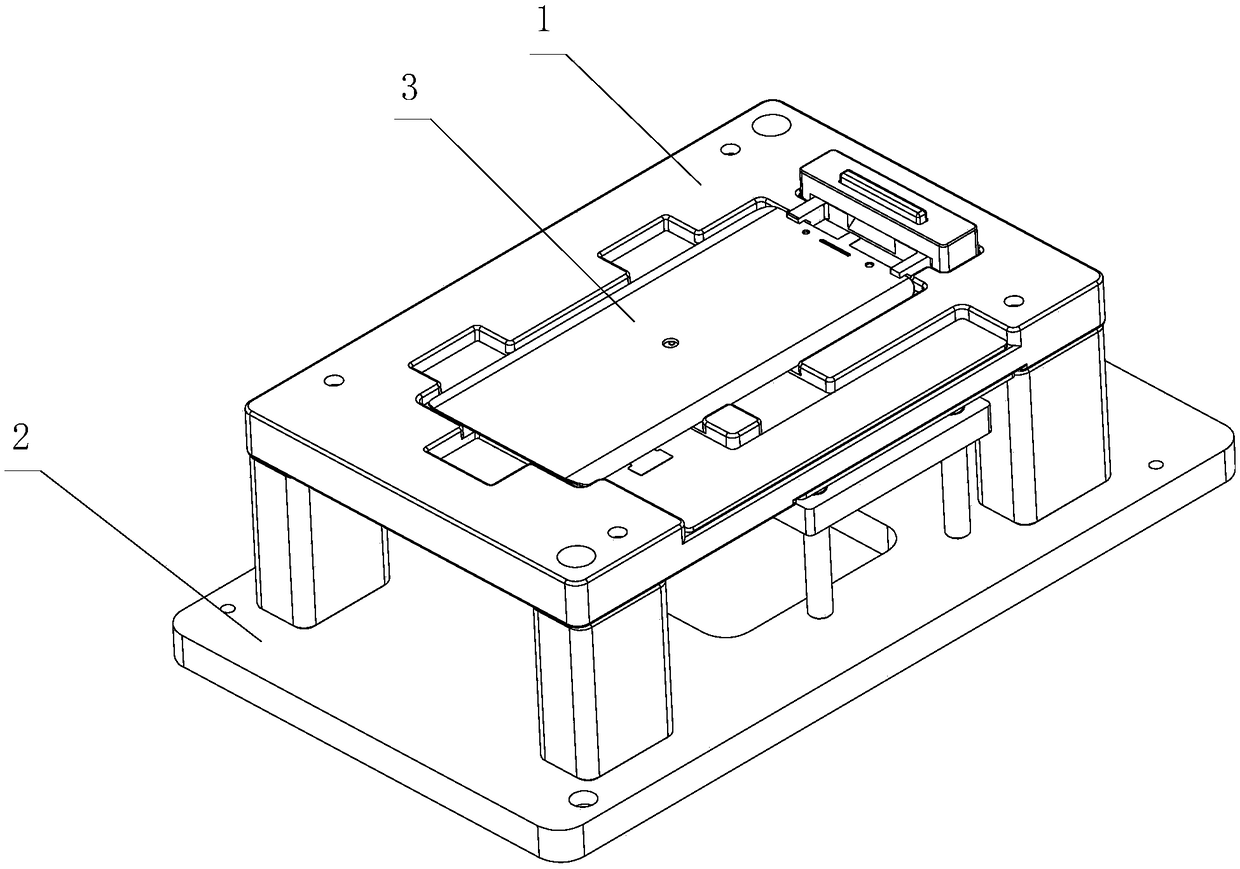

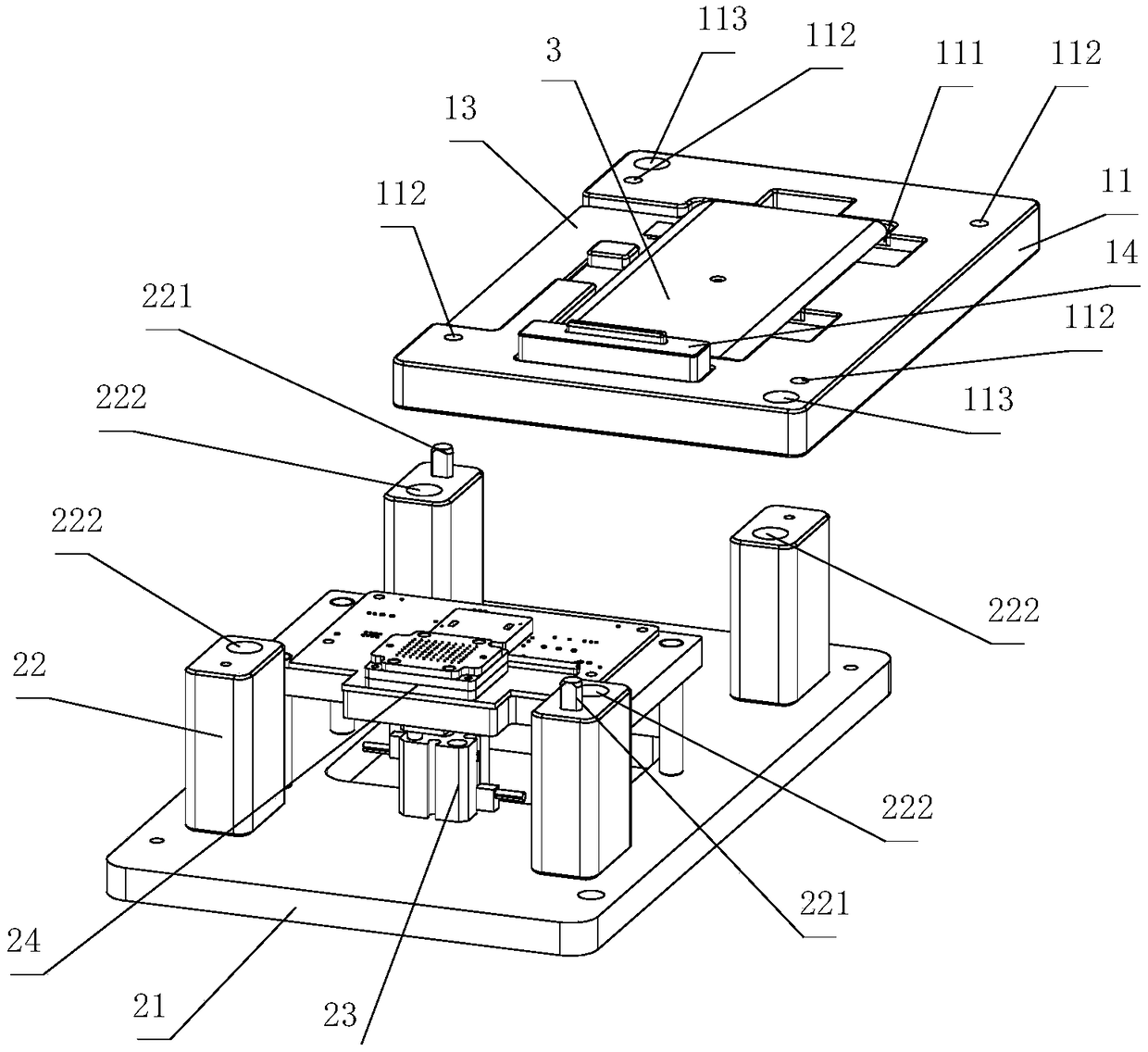

[0025] Such as Figure 1-2 As shown, a display panel test carrying device of the present invention includes a carrier 1 and a test base 2, the display panel 3 to be tested is placed in the groove 1111 of the supporting plate 111 of the carrier 1, and the connector 31 of the display panel 3 Connect with the PCB signal transfer board 13, transmit the detection signal of the display panel 3 to the metal dot matrix 1321 of the PCB signal transfer board 13, and the probes 246 on the probe assembly 24 on the test base 2 contact the metal dot matrix 1321 The probe 246 does not need to be directly connected to the connector 31, which not only protects the product, but also ensures the success rate of conduction. The structure is simple, the operation is convenient, and it is compatible with non-testable stations.

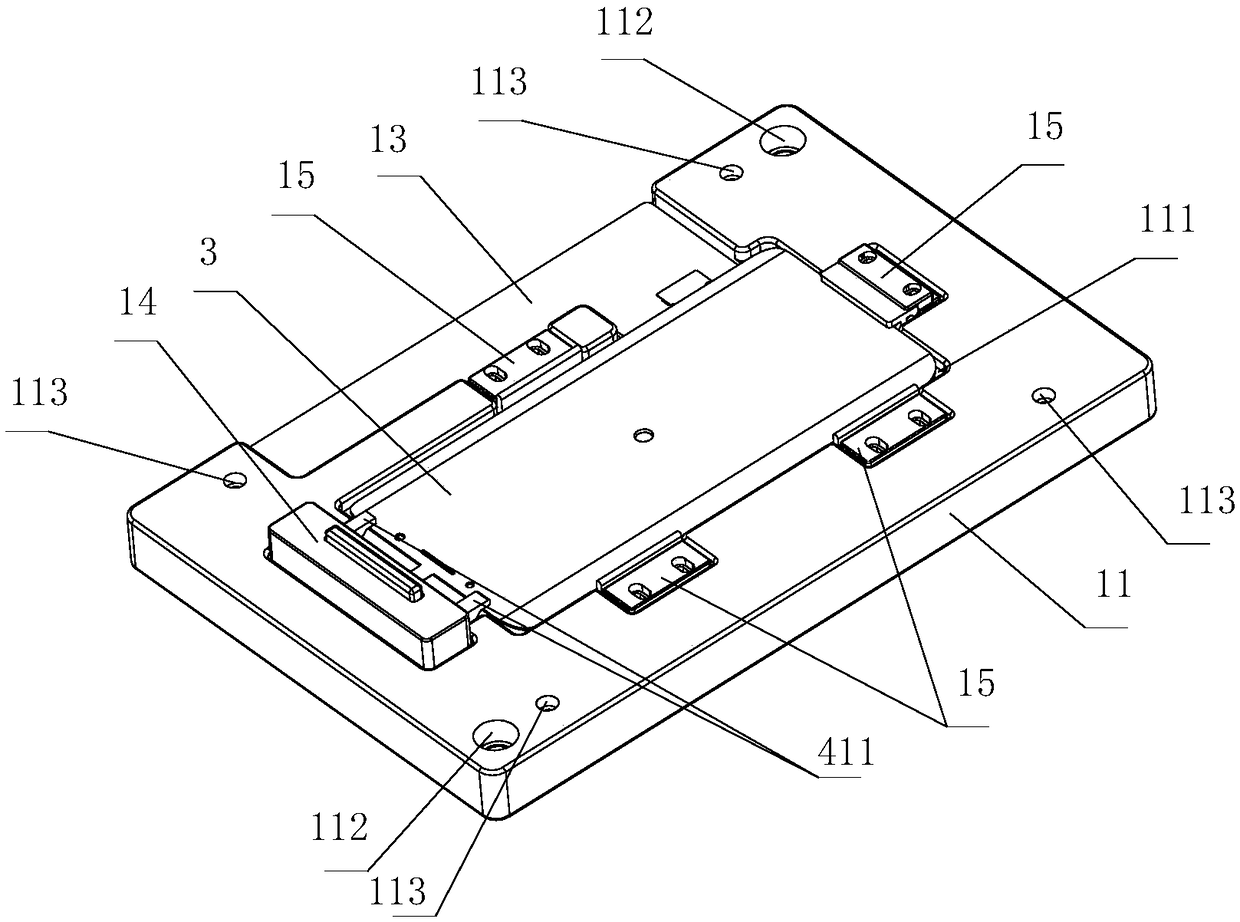

[0026] Such as Figure 3-4 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com