A welding method of 40% silicon carbide particle reinforced aluminum matrix composites with pure Zn as intermediate reaction material layer

A technology of silicon carbide particles and reactive materials, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of difficult formation of metallurgical bonding, hindering the contact between liquid intermediate reaction material layer and aluminum alloy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

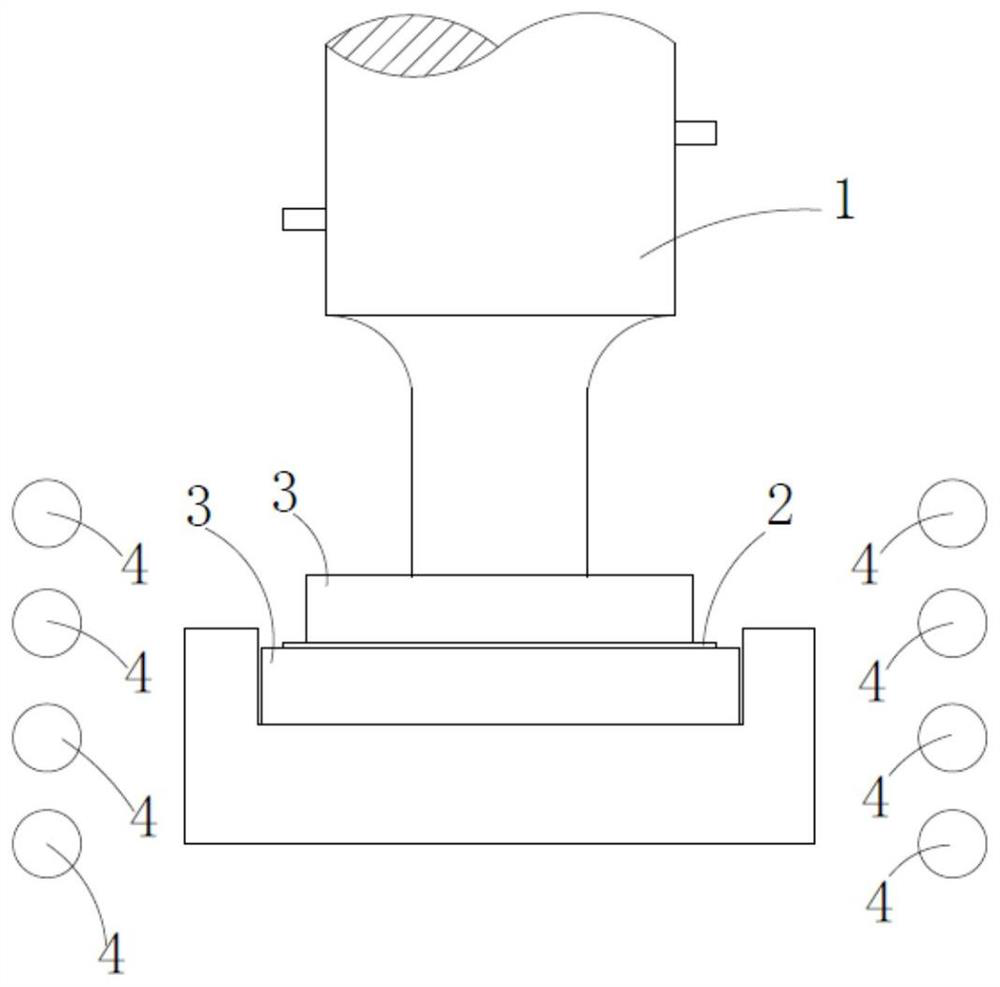

Method used

Image

Examples

Embodiment 2

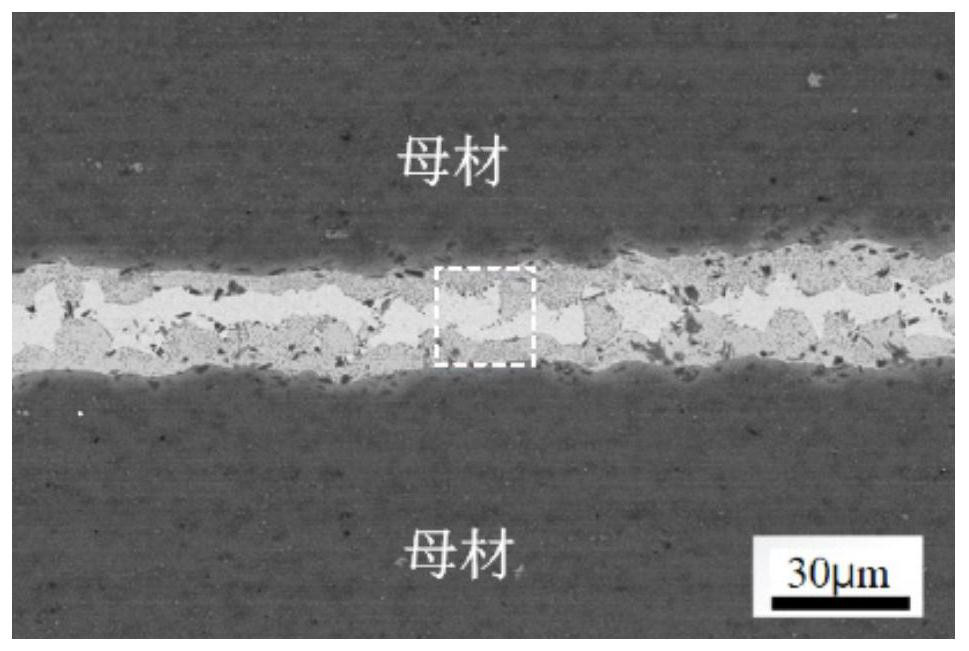

[0097] The main structure, principle and effect of this embodiment are the same as those of Embodiment 1, and will not be repeated here. The difference is that

[0098] In the step of breaking the oxide film and releasing the enhanced phase, the physical state of the base material 3 to be welded is solid, and the physical state of the intermediate reaction material layer 4 is solid;

[0099] In the redistribution step of the reinforcement phase, the physical state of the base material 3 to be welded is solid, and the intermediate reaction material layer 4 disappears and transforms into a full-SiC particle-reinforced α-Al solid solution joint, and the full-SiC particle-reinforced α-Al solid-solution joint The physical state is solid;

[0100] In the step of completing the welding assembly, the physical state of the base metal 3 to be welded is solid, and the physical state of the fully SiC particle reinforced α-Al solid solution joint is solid.

Embodiment 3

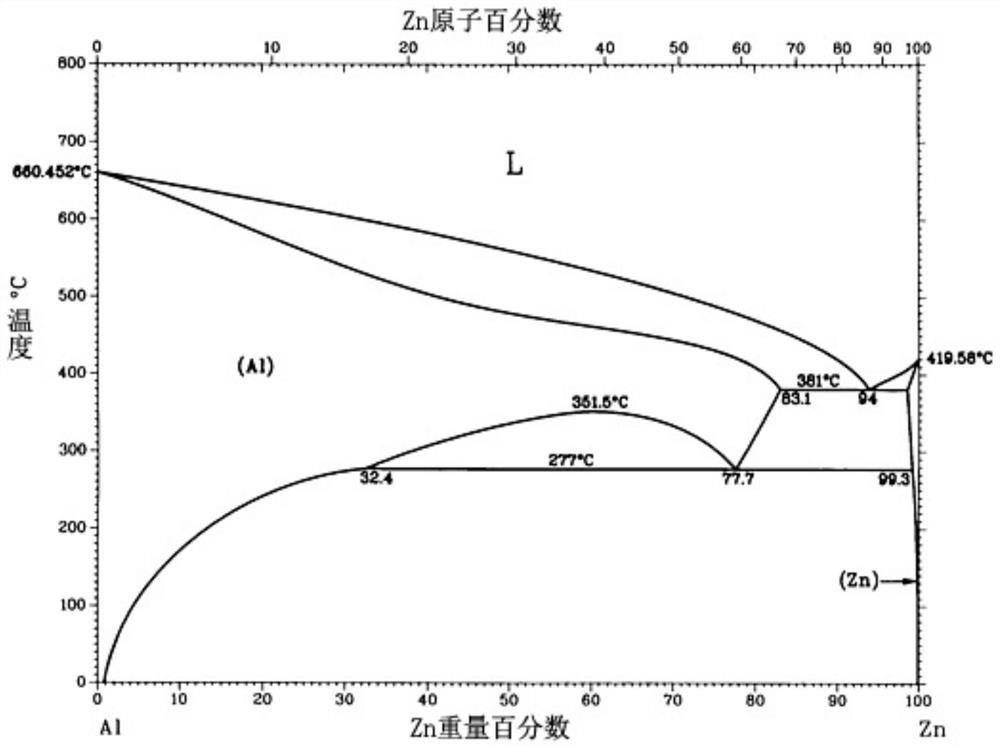

[0102] The main structure, principle and effect of this embodiment are the same as those of Embodiment 1, and will not be repeated here. The difference is that in the steps of breaking the oxide film and enhancing phase release, the reaction temperature of the intermediate reaction material layer 4 is controlled at 400°C. , the application time of welding ultrasonic wave to the assembly to be welded is 10 seconds; in the step of releasing the oxide film and the reinforcement phase and the redistribution step of the reinforcement phase, the application time of the application of welding ultrasonic wave to the assembly to be welded is 210 seconds, the reaction of the intermediate reaction material layer 4 The temperature is controlled at 430°C.

Embodiment 4

[0104] The main structure, principle and effect of this embodiment are the same as those of Embodiment 1, and will not be repeated here. The difference is that in the steps of breaking the oxide film and enhancing phase release, the reaction temperature of the intermediate reaction material layer 4 is controlled at 395°C , the application time of welding ultrasonic wave to the assembly to be welded is 10 seconds; in the step of releasing the oxide film and the reinforcement phase and the redistribution step of the reinforcement phase, the application time of the application of welding ultrasonic wave to the assembly to be welded is 210 seconds, the reaction of the intermediate reaction material layer 4 The temperature was controlled at 425°C.

[0105] Embodiment four

[0106] The main structure, principle and effect of this embodiment are the same as those of Embodiment 1, and will not be repeated here. The difference is that in the steps of breaking the oxide film and enhancing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com