A kind of profiling foil-shaped sandwich solder for aluminum honeycomb plate brazing and preparation method thereof

An aluminum honeycomb, sandwich technology, applied in welding equipment, welding/cutting media/materials, manufacturing tools, etc., can solve the problems of turbulent flow of solder, low efficiency and waste of Al-Si solder foil brazing, and achieve improvement. Plasticity, the effect of improving the mechanical properties of the joint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the present invention comprises the following steps:

[0034] 1) Take two aluminum foils 1 of the same size and weigh them, and calculate the mass of the Ga-In-Sn ternary liquid alloy and the mass of silicon powder according to the mass ratio and the mass of the two aluminum foils 1;

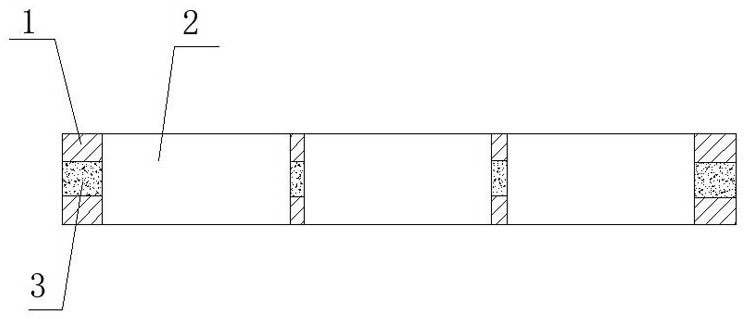

[0035] 2) According to the calculation in step 1), weigh the corresponding mass of Ga-In-Sn ternary liquid alloy and silicon powder, add the silicon powder into the Ga-In-Sn ternary liquid alloy, stir evenly to make a sandwich paste 3 ;

[0036] 3) First, evenly brush the sandwich paste 3 obtained in step 2) on the surface of one side of one aluminum foil 1 in step 1), and then cover the other aluminum foil 1 on the sandwich paste 3 layer, to obtain interlayer aluminum foil 1;

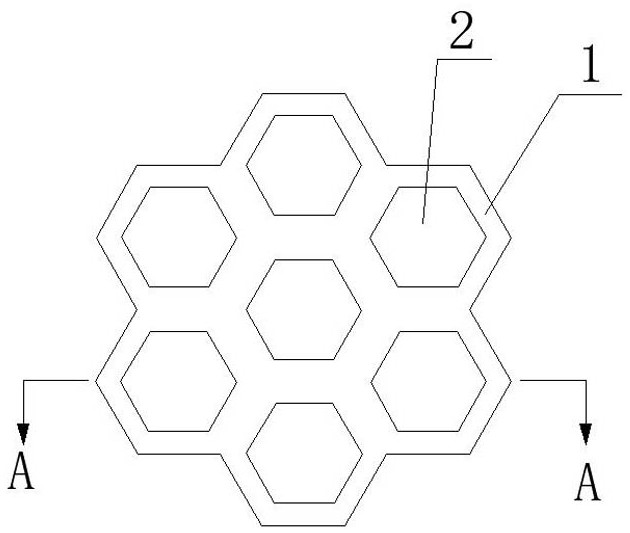

[0037] 4) On the interlayer aluminum foil 1 obtained in step 3), the through holes 2 are cut on the interlayer aluminum foil 1 by a laser cutting machine, and a plurality of through hol...

Embodiment 1

[0040] The aluminum honeycomb plate brazing of the present embodiment is used for profiling foil-shaped sandwich solder component formula: the main component of the solder is Al-Si eutectic, and also includes Ga-In-Sn ternary liquid alloy, and the components of each component are The mass percentage is 91% Al-Si binary eutectic, 9% Ga-In-Sn ternary liquid alloy.

[0041] Preparation:

[0042] 1) Take two pieces of pure aluminum foil 1 with a certain size, and calculate the Ga-In-Sn ternary liquid alloy and Si powder that should be added by the weight of the aluminum foil 1;

[0043] 2) Add Si powder into Ga-In-Sn ternary liquid alloy, stir to make sandwich paste 3;

[0044] 3) Evenly brush the sandwich paste 3 on the surface of one of the aluminum foils 1, and completely cover it with the other aluminum foil 1 to obtain the interlayer aluminum foil 1;

[0045] 4) Fix the interlayer aluminum foil 1 obtained in step 3), and process it into honeycomb-shaped profiling foil-shape...

Embodiment 2

[0047] The profiling foil-shaped sandwich solder component formula for aluminum honeycomb plate brazing of the present invention: the main component of the solder is Al-Si eutectic, and also includes Ga-In-Sn ternary liquid alloy, and the mass of each component is The percentage is 92% Al-Si binary eutectic, 8% Ga-In-Sn ternary liquid alloy.

[0048] Preparation method: the same preparation method as in Example 1, the melting point of the solder is 480°C to 485°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com