Large heat input electro-gas welding flux-cored wire and preparation method thereof

A technology of flux-cored welding wire and gas-electric vertical welding, which is applied to welding equipment, welding media, manufacturing tools, etc., and can solve problems such as coarse microstructure of weld metal, poor mechanical properties, and inability to realize high-efficiency welding of medium and thick plates. , to achieve the effect of ensuring mechanical properties and improving welding manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

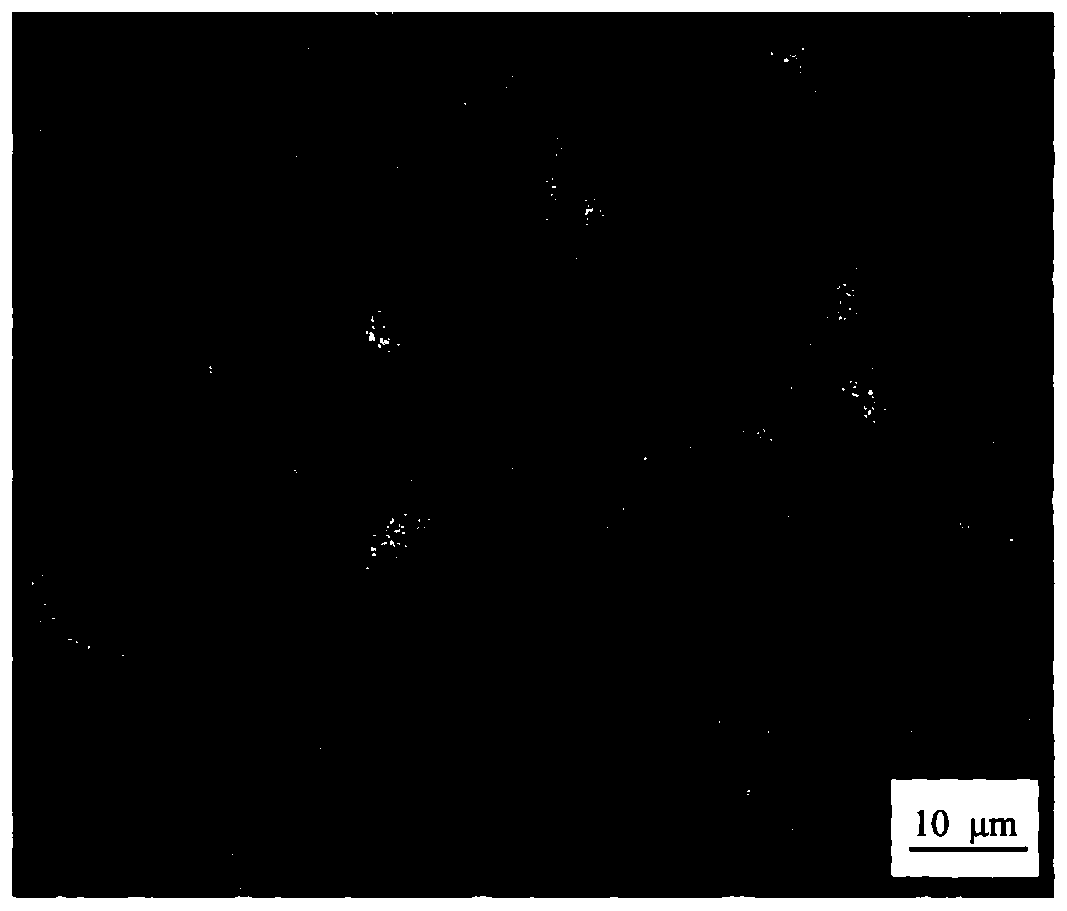

Image

Examples

preparation example Construction

[0044] A method for preparing a large heat input gas-electric vertical welding flux-cored wire, comprising the following steps:

[0045] (1) Weigh each raw material component according to the stoichiometric ratio, and then fully stir, mix and dry in order to prepare the flux-cored wire formula powder;

[0046] (2) Cut the steel strip with preset specifications, and then perform ultrasonic cleaning, degreasing, rust removal, drying and rolling into a U-shaped groove in sequence, and then pour the flux cored wire formula powder into the U-shaped groove of the steel strip After closing, reducing diameter, drawing, and winding up, the high heat input gas-electric vertical welding flux-cored wire is produced.

[0047] Further, the steel strip in step (2) has a thickness of 0.8 mm and a width of 12 mm.

[0048] Further, the powder filling rate of the high heat input gas-electric vertical welding flux-cored wire prepared in step (2) is 18%±5%.

[0049] Further, the diameter of the ...

Embodiment 1

[0052] A method for preparing a large heat input gas-electric vertical welding flux-cored wire, comprising the following steps:

[0053] (1) According to reduced iron powder 53.5%, low carbon ferromanganese powder 19%, nickel powder 8%, magnesium powder 1.2%, fluoride 2.3%, quartz 3.3%, rutile 3.5%, molybdenum iron 1%, boron iron 0.5% %, ferro-titanium 5.5%, aluminum powder 2.2% stoichiometrically weigh various powder raw materials, fully stir, mix evenly, and dry to obtain flux-cored wire formula powder;

[0054] (2) Cut the steel strip with a thickness of 0.8mm, use ultrasonic cleaning, degrease, derust, dry, and roll into a U-shaped groove, pour the metal mixed powder described in step (1) into the U-shaped groove, and pass Closing, diameter reduction, drawing, wire take-up, and finally forming a flux-cored wire with a diameter of 1.6mm.

[0055] The prepared large heat input flux-cored wire was welded under the welding condition of 276 kJ / cm gas-electric vertical welding....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com