An intermediate layer alloy for tantalum/stainless steel energy storage welding, its preparation method and welding method

An intermediate layer and stainless steel technology, applied in energy storage discharge welding, welding equipment, welding medium, etc., can solve the problems of hard and brittle intermetallic compounds, difficult to obtain high-performance tantalum-steel composite structure, etc., and achieve comprehensive mechanical properties of joints Improvement, low cost, good matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

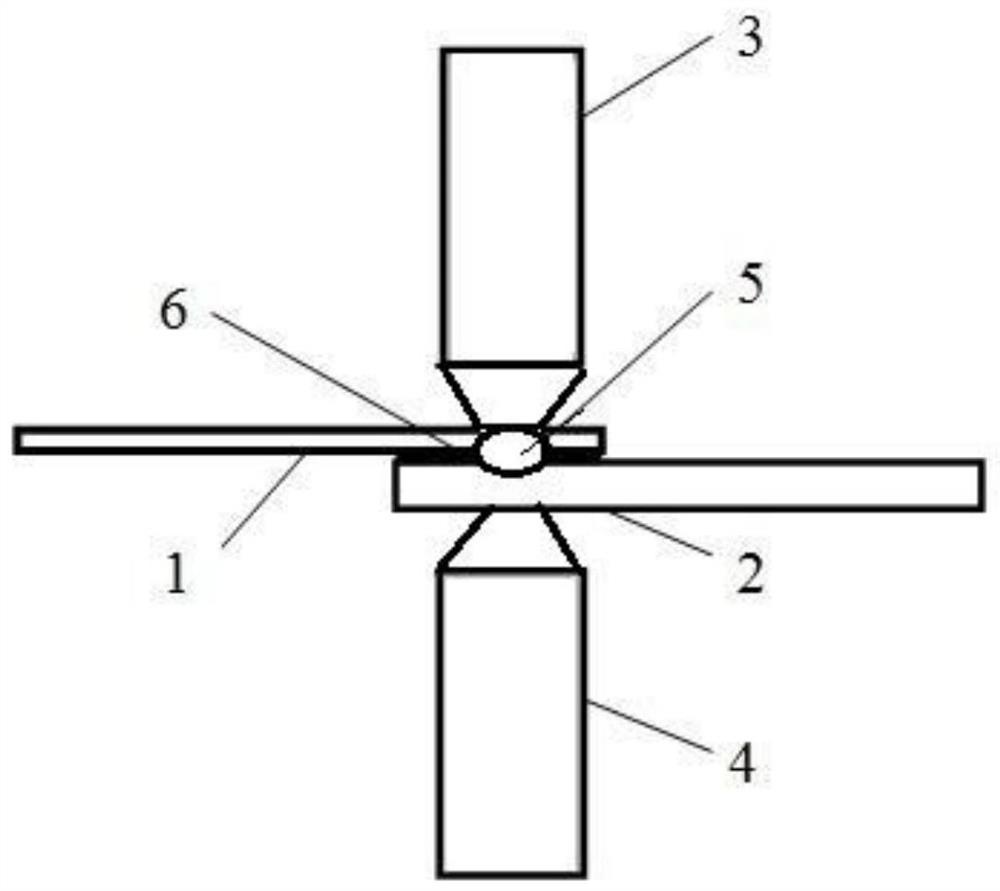

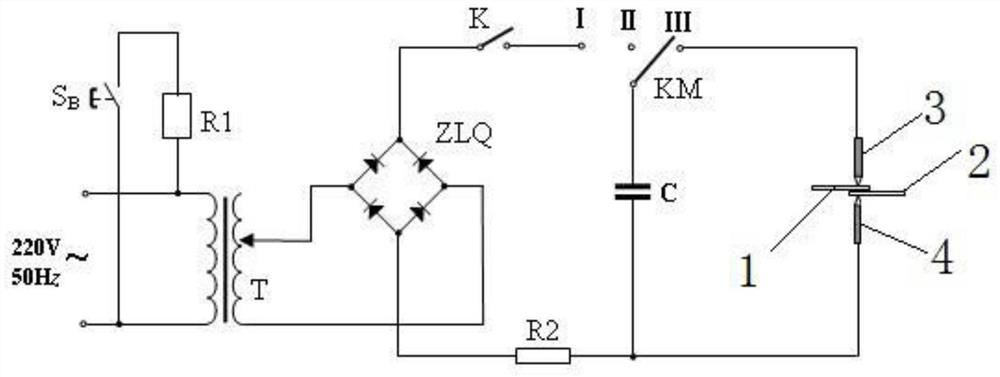

Method used

Image

Examples

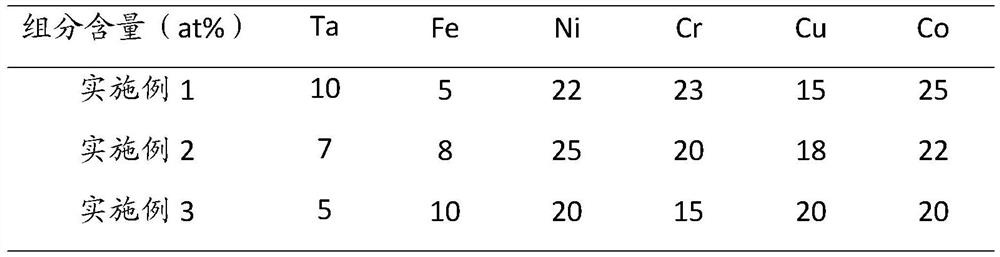

Embodiment 1

[0049] According to the preparation method of the above-mentioned high-entropy interlayer alloy, select the elements and contents of each component according to the data of the high-entropy interlayer alloy Example 1 listed in Table 1, and control the roll surface line speed at 5m / s, and prepare a product with a thickness of about 5m / s. Ta of 130μm, width about 5mm, length about 0.5m 10 Fe 5 Ni 22 Cr 23 Cu 15 co 25 High entropy interlayer alloy foil. Set the working parameters of the energy storage welding machine: welding voltage U=900V, welding pressure F=40kN, capacitance C=1500μF. The high-entropy intermediate layer alloy foil is used to perform energy storage welding on tantalum / steel, and the strength of the welded joint is about 305MPa.

Embodiment 2

[0051] According to the preparation method of the above-mentioned high-entropy interlayer alloy, the elements and contents of each component are selected according to the data of the high-entropy interlayer alloy Example 2 listed in Table 1, and the surface speed of the roll is controlled at 5m / s to prepare a product with a thickness of approx. Ta of 130μm, width about 5mm, length about 0.5m 7 Fe 8 Ni 25 Cr 20 Cu 18 co 22 High entropy interlayer alloy foil. Set the working parameters of the energy storage welding machine: welding voltage U=1000V, welding pressure F=35kN, capacitance C=1000μF. The high-entropy intermediate layer alloy foil is used to perform energy storage welding on tantalum / steel, and the strength of the welded joint is about 340MPa.

Embodiment 3

[0053] According to the preparation method of the above-mentioned high-entropy interlayer alloy, the elements and contents of each component are selected according to the data of the high-entropy interlayer alloy Example 3 listed in Table 1, and the surface speed of the roll is controlled at 5m / s to prepare a product with a thickness of approx. Ta of 130μm, width about 5mm, length about 0.5m 5 Fe 10 Ni 20 Cr 15 Cu 20 co 20 High entropy interlayer alloy foil. Set the working parameters of the energy storage welding machine: welding voltage U=1100V, welding pressure F=30kN, capacitance C=500μF. The high-entropy intermediate layer alloy foil was used to perform energy storage welding on tantalum / steel, and the strength of the welded joint was about 289MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com