Method for welding T-shaped movable beam for deformed glass machining system

A processing system and special-shaped glass technology, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as difficulty in applying high-precision welding operations, difficulty in ensuring horizontal accuracy, and affecting welding quality, so as to achieve ideal processing effects and structural Good rigidity and beautiful processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

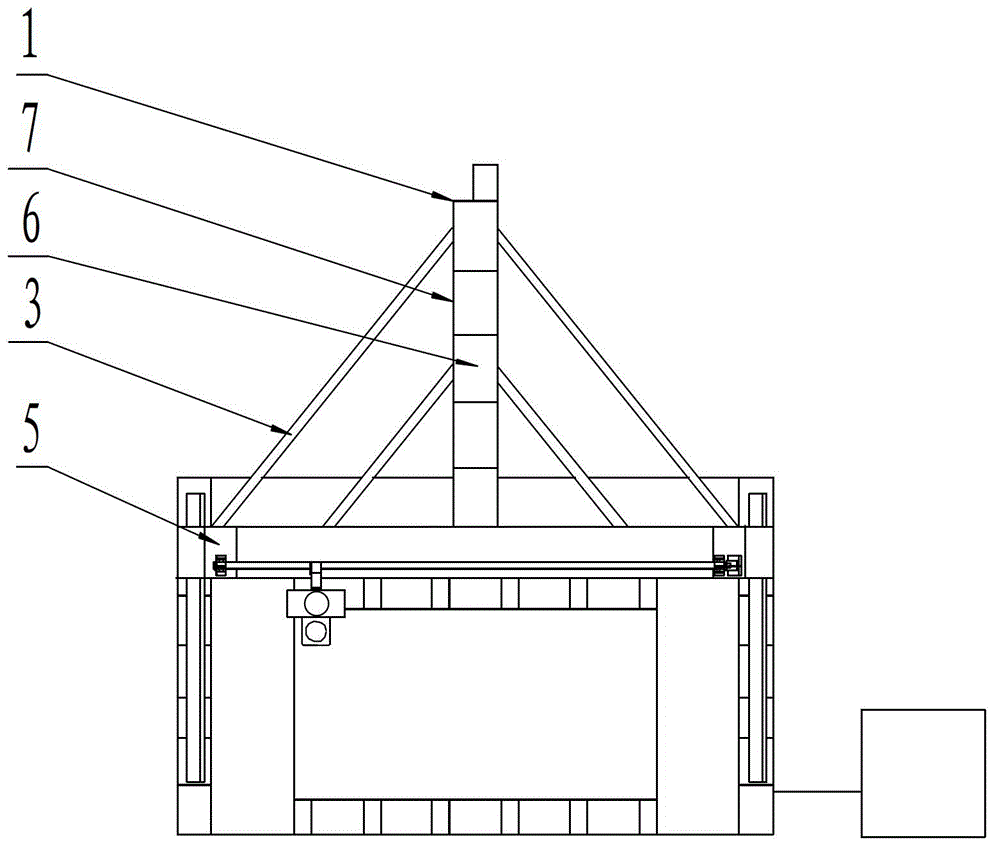

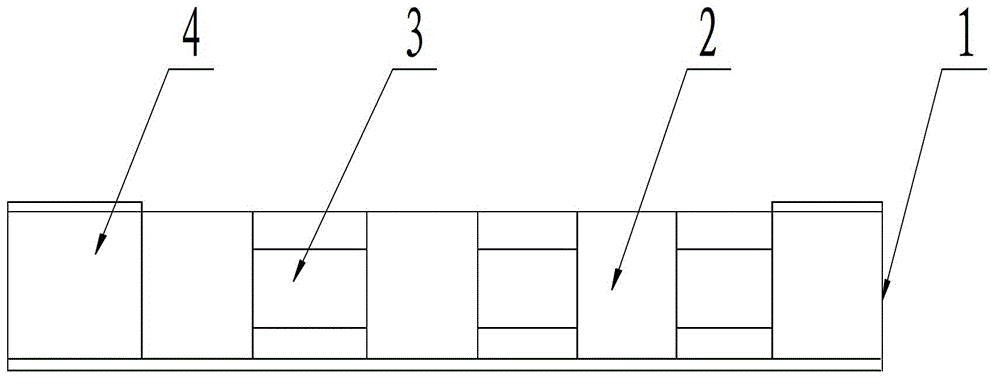

[0025] The T-shaped mobile beam adopts an overall frame structure, which is welded by rib plate 2, channel steel 3, square tube 4, bottom plate 6, vertical plate 6, and reference plane. The rib plate 2, channel steel 3, square tube 4, The thickness of the bottom plate 6 and the vertical plate 7 are both 10mm-15mm. The rib plate 2 is welded into a rectangular rib plate 2 on the automatic rotary welding equipment, and the channel steel 3 is welded into a rectangular channel steel 3 on the automatic rotary welding equipment. 3. The welding seam is Y-shaped during welding, and the rectangular rib plate 2 and the rectangular channel steel 3 are welded into a rectangular long column on the automatic rotary welding equipment. When the rectangular rib plate 2 and the rectangular channel steel 3 are welded, the weld seam is Y-shaped. When welding on automatic rotary welding equipment, resistance welding is used, and then carbon dioxide gas shielded double-gun symmetrical welding is used...

Embodiment 2

[0027] The welding method of the rectangular ribbed plate 2 is to clean the surfaces to be welded of the four ribbed plates 2, fix the four ribbed plates 2 in a rectangular shape on the automatic rotary welding equipment, and press the welding surface of the two adjacent ribbed plates 2 at 90 Align the four ribs 2 in a rectangular shape, the gap between the welds to be welded is 0.1mm-2mm, the resistance welding process parameters are preferably: welding wire diameter 1.5mm-2.0mm, welding current 400A-500A, welding voltage The power is 32V-36V, the power-on time is 2min, and the four welds are spot-welded by resistance welding, and then the symmetrical welds are grounded at the same time, welding to 2 / 3 of the weld bead, and the four welds are finished. Finally, use carbon dioxide gas protection double gun symmetrical welding to carry out horizontal welding on the symmetrical weld seam at the same time. The horizontal welding process parameters are preferably: the diameter of t...

Embodiment 3

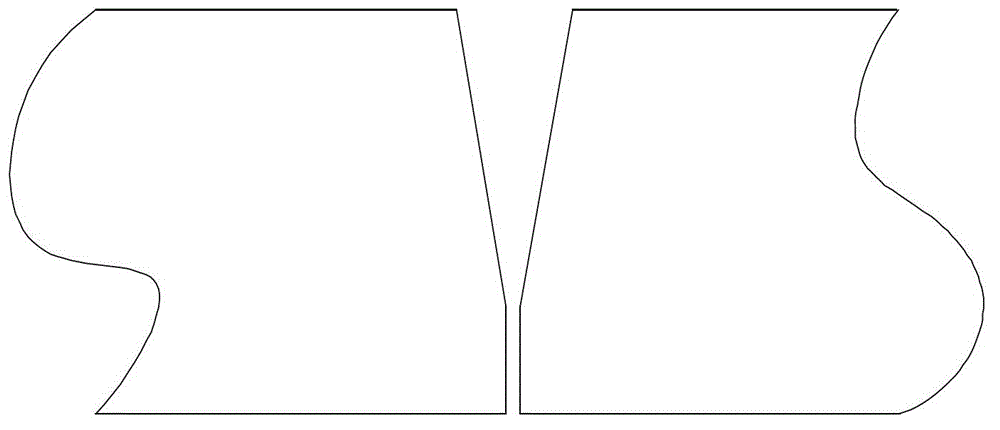

[0029] The welding method of rectangular channel steel 3 is to clean the surfaces to be welded of two pieces of channel steel 3, and process the weld seam on the surface to be welded into a Y shape, the gap between the weld seams is 0.1mm-2mm, and the slope of the Y-shaped weld seam The mouth angle is 6 degrees to 15 degrees, the height of the blunt edge is 1mm-3mm, two pieces of channel steel 3 are fixed on the automatic rotary welding equipment in a rectangular shape, and the surfaces to be welded are aligned. The resistance welding process parameters are preferably: the diameter of the welding wire is 1.0mm-1.5mm, the welding current is 400A-500A, the welding voltage is 32V-36V, and the power-on time is 2min. Use resistance welding to spot weld two welds, and use resistance welding to weld symmetrical weld grooves at the same time Bottom welding, welded to 2 / 3 of the weld groove, after the bottom welding of the two welds of rectangular channel steel 3 is completed, use carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com