A continuous-roll plastic film self-pressing type double-sided scrap material tempered glass laminating machine

A technology of tempered glass and plastic film, used in metal processing and other directions, can solve problems such as troublesome positioning of the rear glass plate and offset of the outer film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

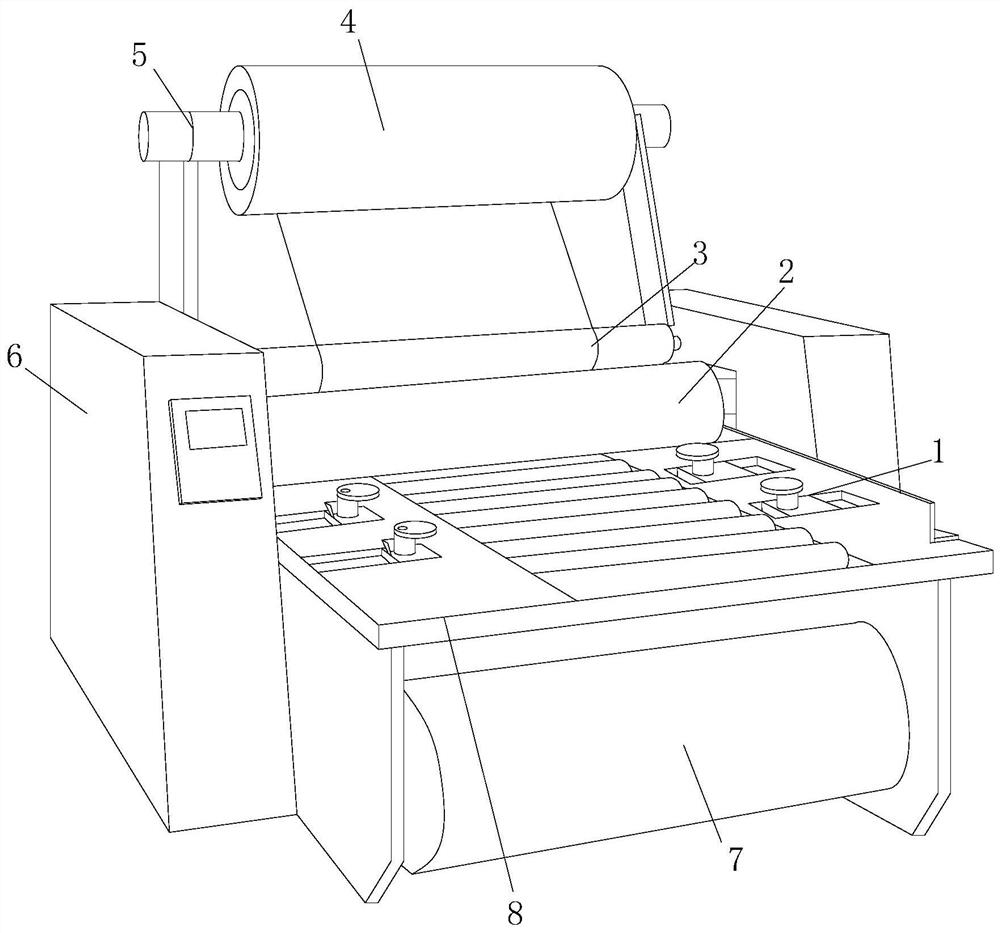

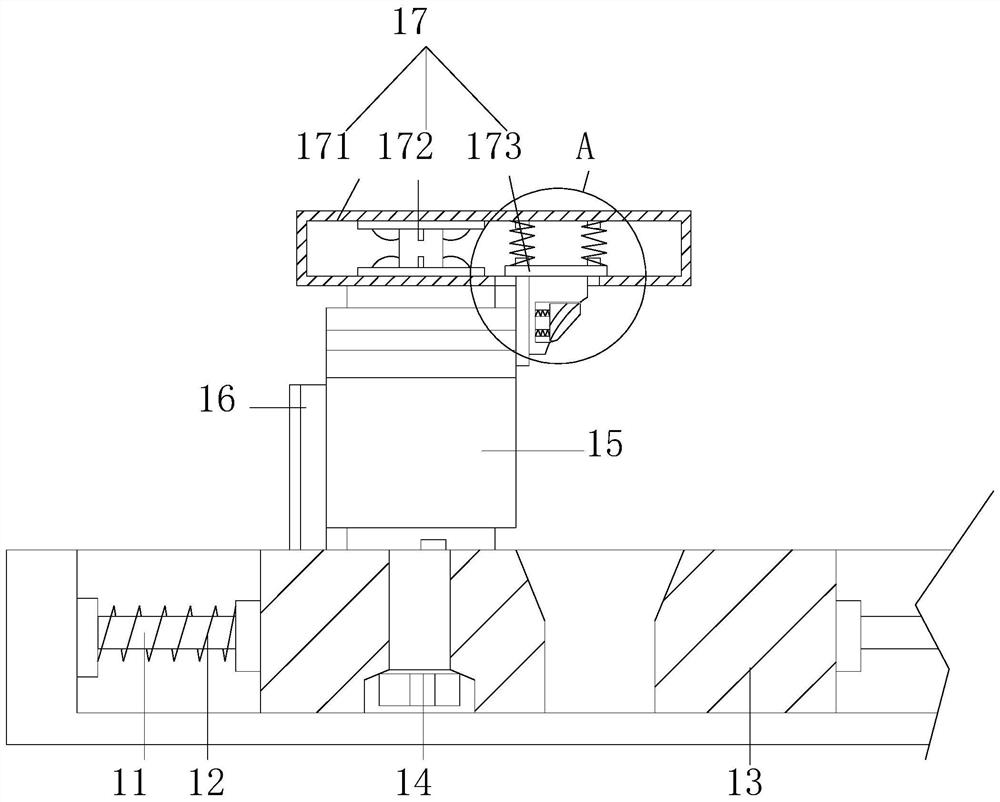

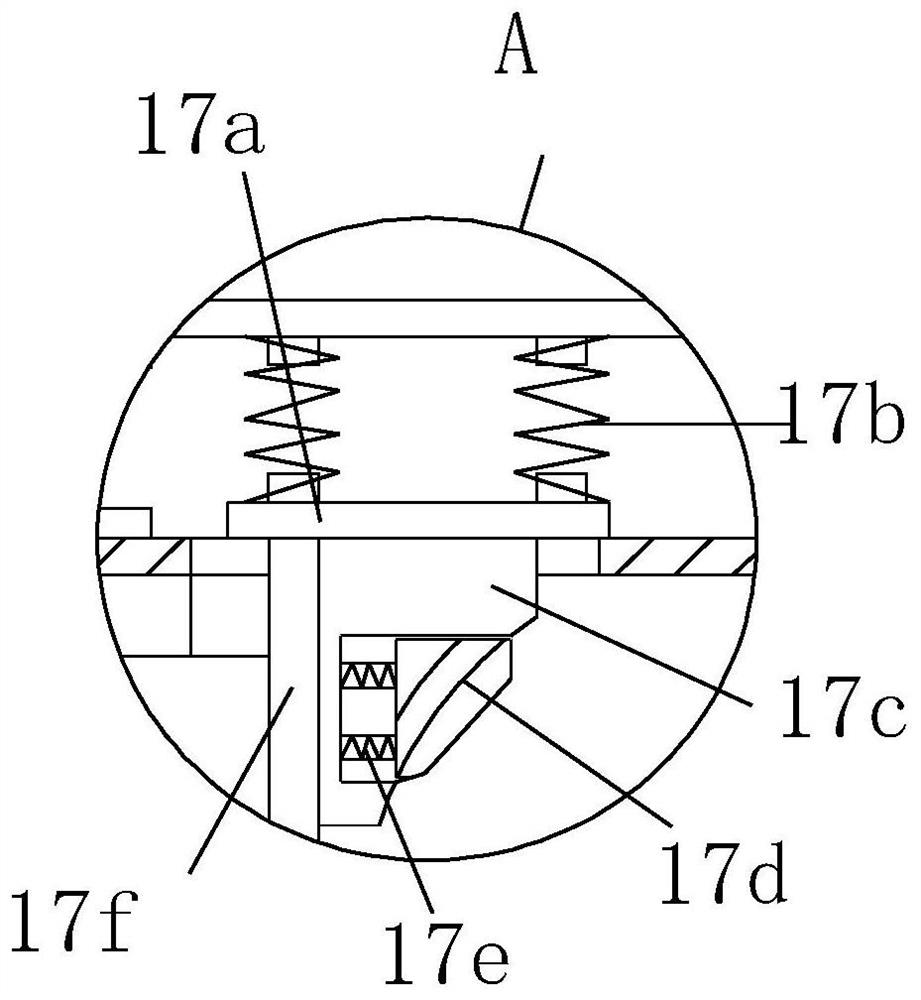

[0026] Such as Figure 1-Figure 4 As shown, the present invention provides a continuous roll type plastic film self-pressing type double-sided scrap material tempered glass laminating machine, its structure includes: trimming device 1, pressure roller 2, guide roller 3, roll film 4, roll film support 5. Base 6, mobile platform 7, reverse pressure roller 8, the trimming device 1 is provided with four upper ends of the mobile platform 7 evenly fixed on the pressure roller 2, and the gap is inward, the pressure roller 2 Installed horizontally on the bottom of the guide roller 3, the roll film 4 is parallel to the pressure roller 2 installed at the bottom of the guide roll 3, the two sides of the roll film support 5 are welded and fixed on the upper end of the base 6, and are connected to the roll film 4 The center is movably connected, and the outer walls on both sides of the mobile platform 7 are close to the inner surface wall of the base 6 and integrated into one body. The rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com