Oil-pneumatic spring rear suspension system of a mining vehicle

A technology of oil-pneumatic springs and rear suspensions, applied in the direction of vehicle springs, elastic suspensions, suspensions, etc., can solve the problems of short service life, poor vehicle carrying capacity, poor comfort, etc., and achieve improved fuel consumption and light weight Improvement and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

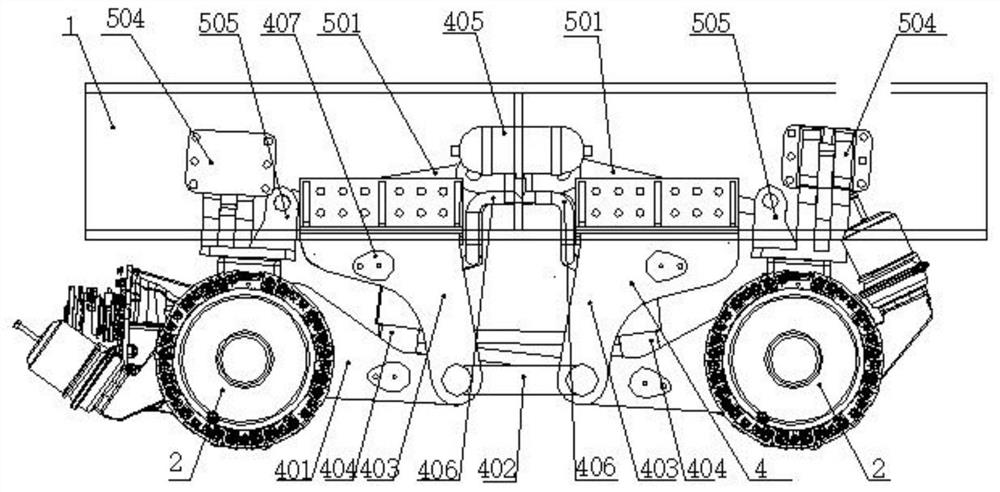

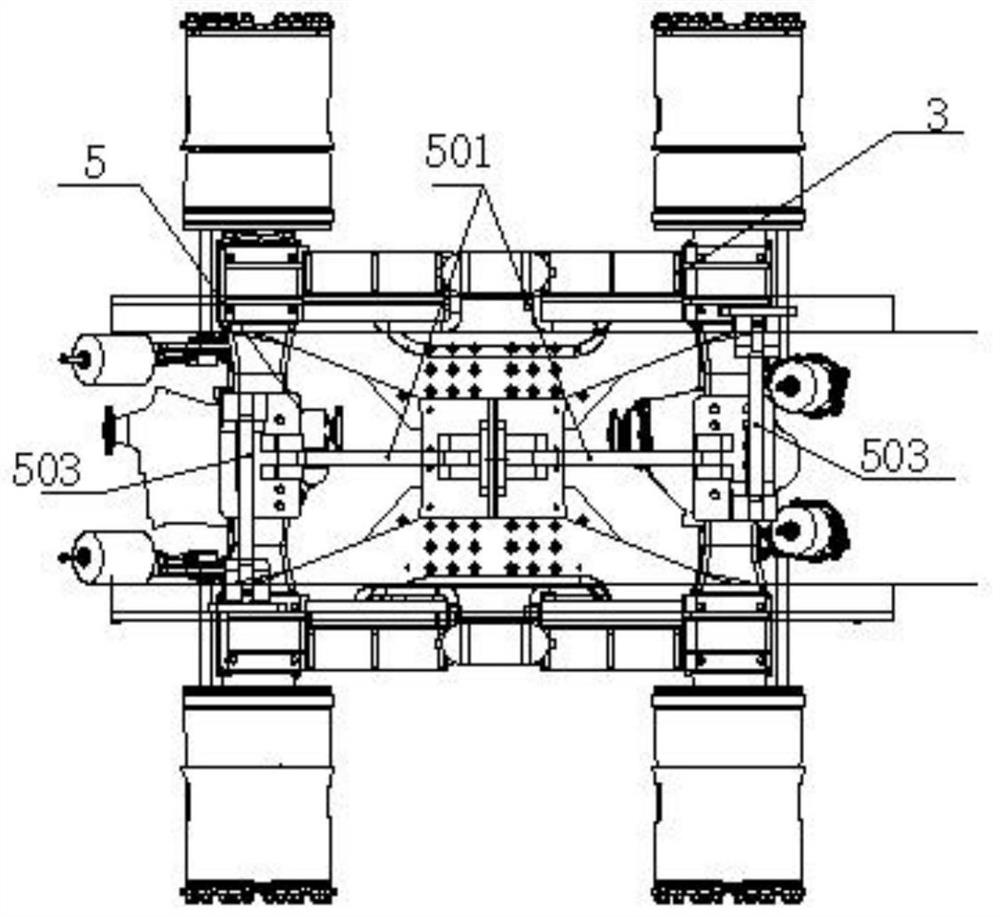

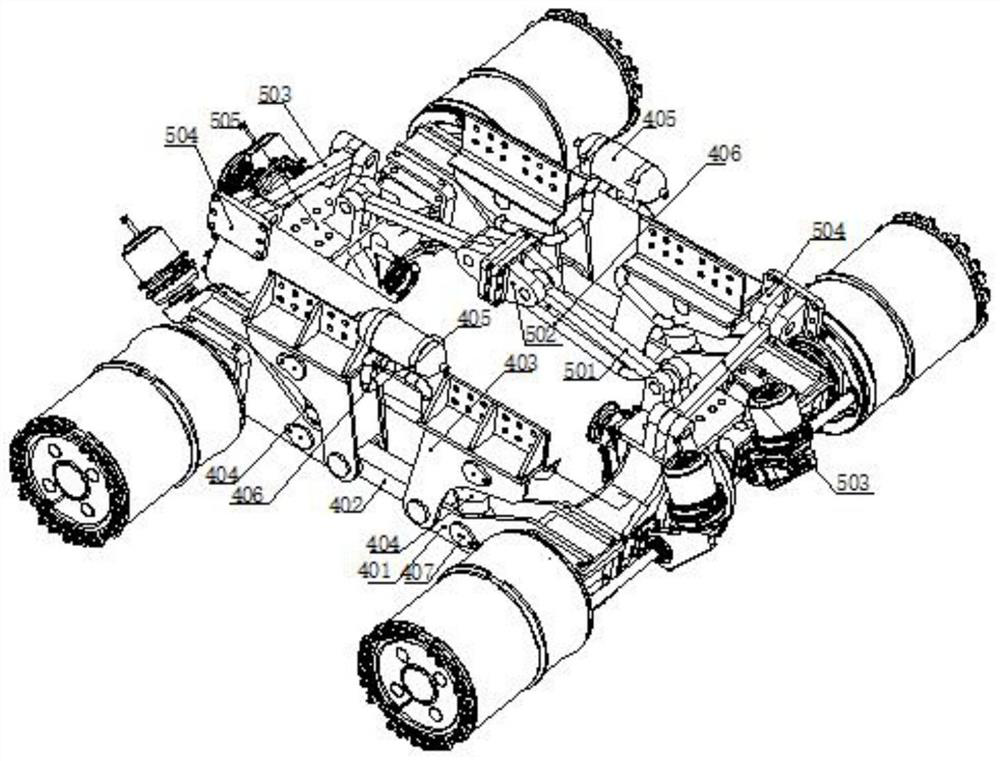

[0035] Such as Figure 1-2 As shown, a kind of mining vehicle oil-pneumatic spring rear suspension system provided by the present invention includes a vehicle frame 1 and a suspension mechanism 3 installed on the vehicle axle 2, and the vehicle frame 1 is installed on the suspension mechanism 3, The suspension mechanism 3 includes two sets of carrying mechanisms 4 and one set of guiding mechanisms 5; the carrying mechanisms 4 are installed on both sides of the vehicle frame 1 at intervals, and the lower part of the carrying mechanisms 4 is connected to the axle 2; Mechanism 5 is installed in vehicle frame 1 inside; Vehicle axle among the present invention comprises middle axle and rear axle, and suspension mechanism 4 is for connecting middle axle and rear axle, and carrying mechanism 4 among the present invention comprises oil-pneumatic spring, like this Can bear all vertical loads, and improve the reliability of the automobile with the characteristics of non-linear elastic v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com