Guide mechanism of conveying chain

A conveyor chain and guide rod technology, applied in conveyors, transportation, packaging, packaging, etc., can solve the problems of large noise pollution, expensive conveyor chains, etc., to reduce maintenance and use costs, eliminate noise pollution, and extend service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

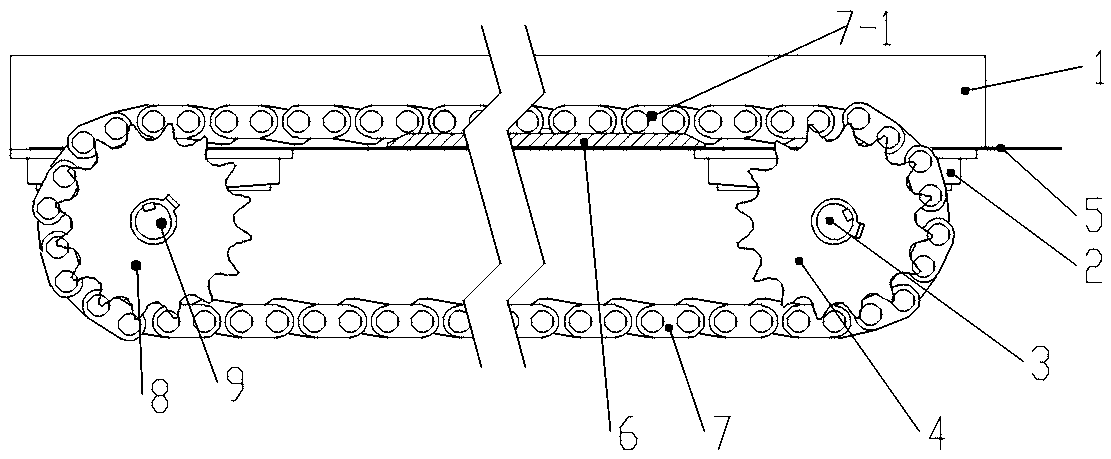

[0013] Such as figure 1 As shown, a guiding mechanism of a conveyor chain includes a conveyor sprocket, a conveyor chain, a lifting pallet and a guide rod; the conveyor chain is divided into a driving sprocket 4 and a driven sprocket 8, and the driving sprocket 4 and the drive shaft 3-key connection, the drive shaft 3 is supported on the mounting bracket 1 by the bearing assembly 2, and connected to the driving device; the driven sprocket 8 is key-connected to the rotating shaft 9 installed on the bearing assembly 2, and the conveyor chain 7 is linked to the drive sprocket 4 and the driven sprocket 8, so that the driving sprocket 4 can drive the driven sprocket 8 to rotate; the lifting pallet 5 is also installed on the mounting bracket 1, and the lifting pallet 5 is connected to the mounting bracket 1 or the bearing assembly 2 through bolts Connected, located below the uplink chain 7-1; a guide rod 6 is fixedly connected to the lifting pallet 5, the guide rod 6 is cylindrical,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com