Rapid loading and unloading system of freight train

A technology for freight trains and loading and unloading systems, applied in the field of freight train installations, can solve the problems of inability to keep up with the Internet of Things, complicated procedures, and many intermediate links, so as to reduce pollution such as exhaust emissions, improve social effects, and save time and costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

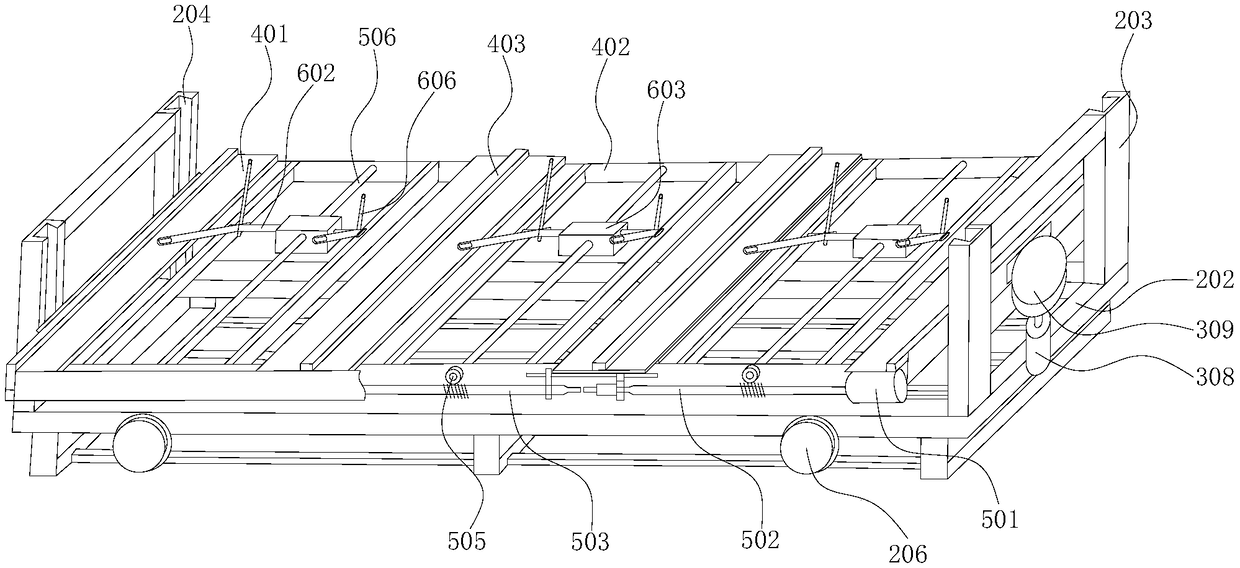

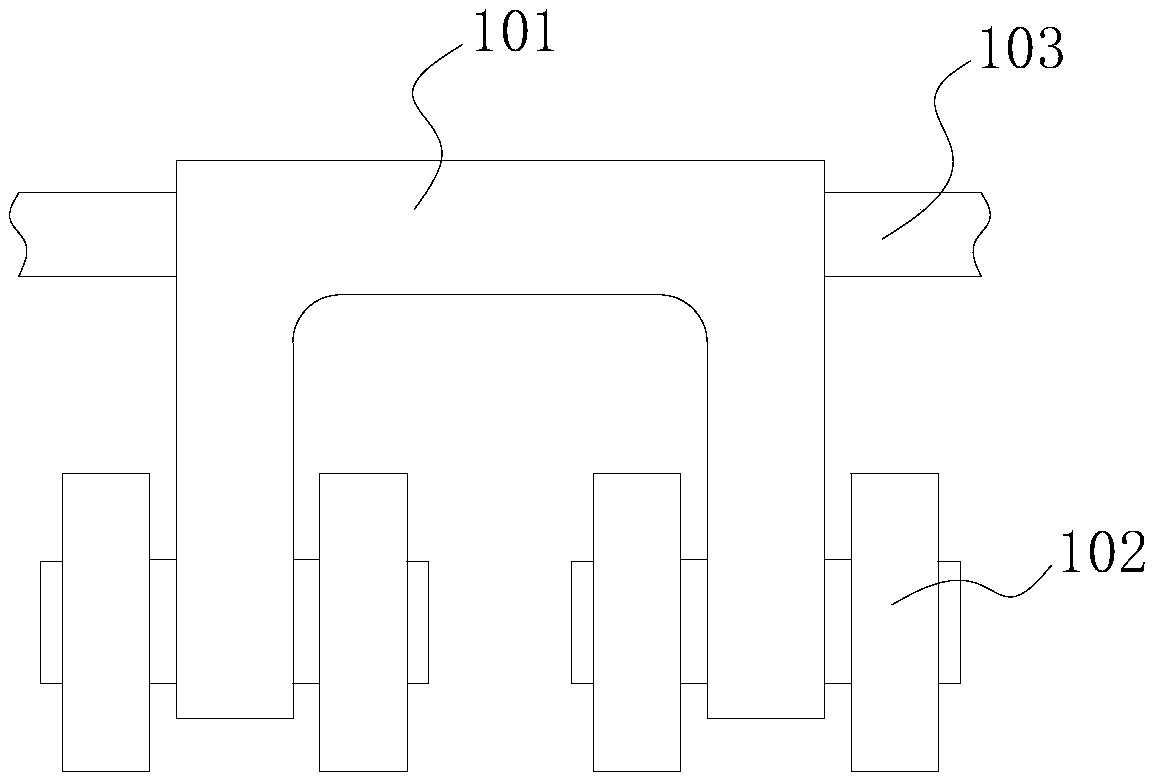

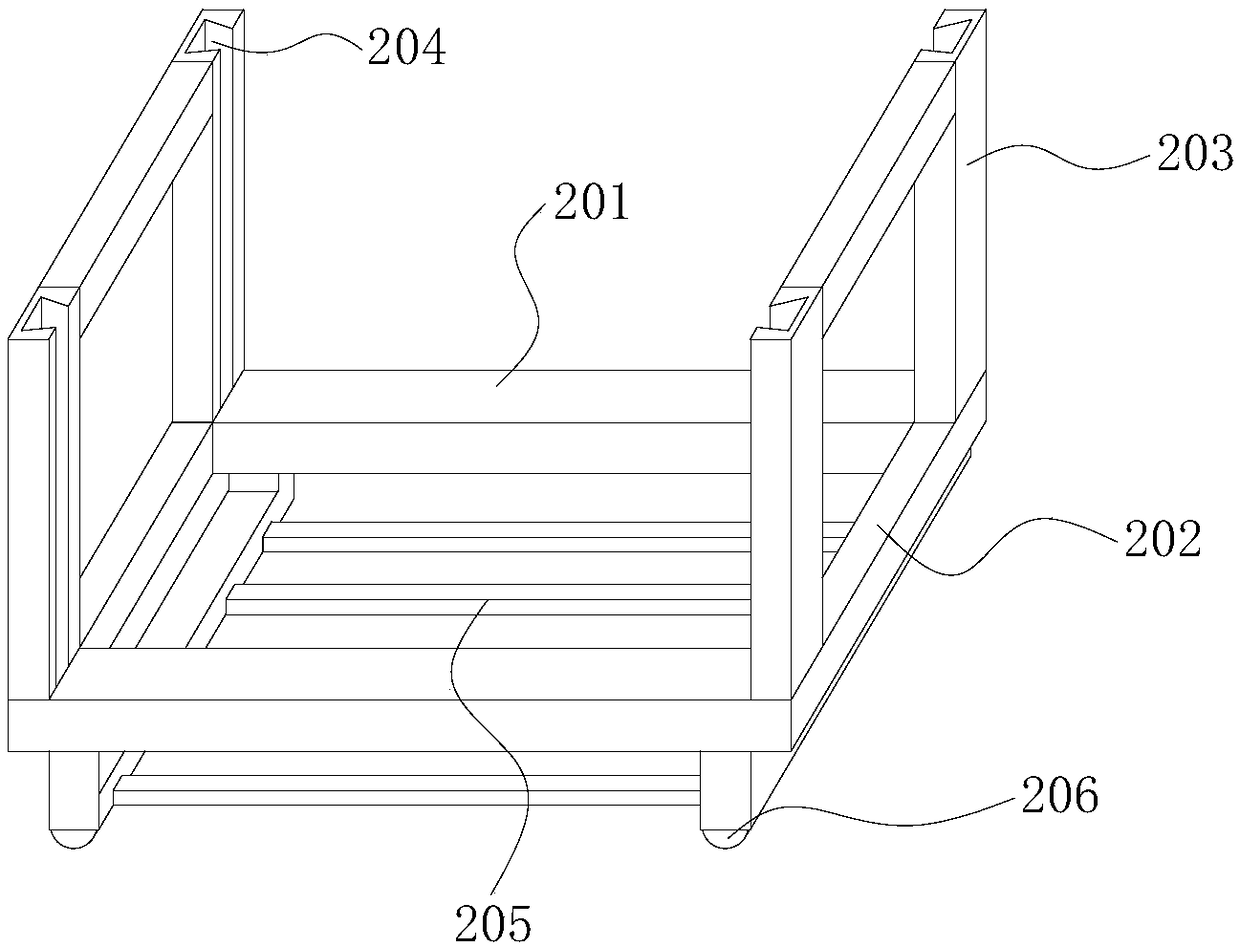

[0041] Such as Figure 1-12 As shown, the present embodiment provides a fast loading and unloading system for freight trains, including a loading and unloading bridge installed on both sides of the freight train and a sliding mechanism installed on the container of the freight train, the sliding mechanism is provided with moving wheels that slide on the loading and unloading bridge 102. It is convenient for the container to move on the loading and unloading bridge by means of a sliding mechanism; the loading and unloading bridge includes an upper platform, a middle load-bearing frame and a bottom frame that are installed sequentially from top to bottom. The bottom frame is provided with a vertical chute 204, and the middle load-bearing frame The two sides of the frame are fixed with slide blocks 303 that are installed in the vertical chute 204 to facilitate the disassembly and assembly of the middle load-bearing frame. The upper end of the middle load-bearing frame is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com