Simple and practical ferrule coating device

A coating device and a practical technology are applied in the field of optical communication active connector coating, which can solve the problems of low coating yield, cumbersome upper plate protection, difficult coating, etc., so as to reduce the problem of coil breakage, reduce waste of operating hours, and reduce up and down The effect of disk protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

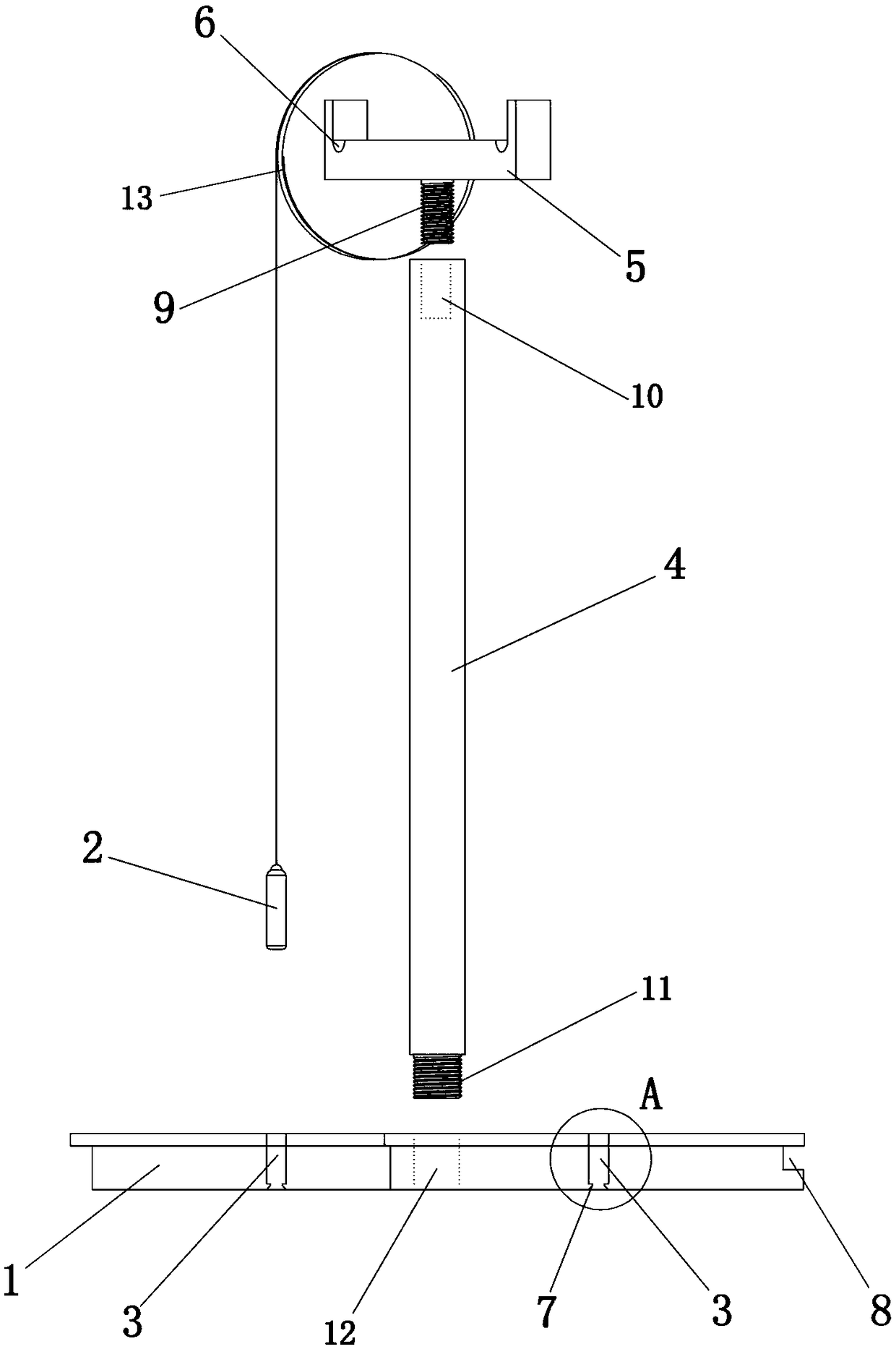

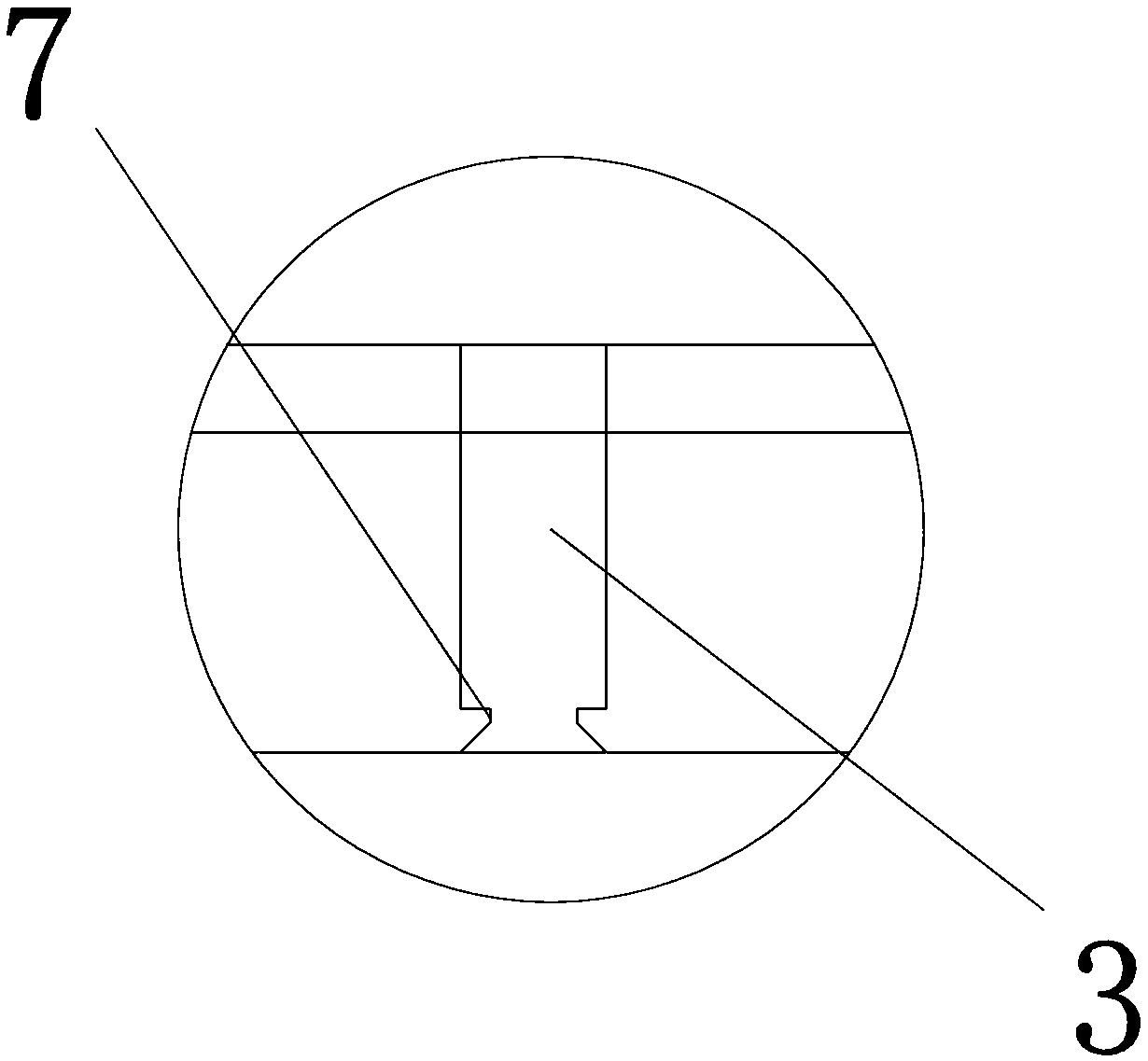

[0017] A simple and practical ferrule coating device, such as figure 1 , figure 2 As shown, the fixture body 1 is included, and the fixture body 1 is provided with several storage holes 3 that match the fiber optic ceramic ferrule 2; the fixture body 1 is connected with a support rod 4, and the lower end of the support rod 4 is a threaded rod 11, and the threaded rod 11 is connected with the second threaded hole 12 on the clamp body 1; the upper end of the support rod 4 is connected with a hanging wire bracket 5, and the bottom of the hanging wire bracket 5 is provided with a threaded rod 9, and the threaded rod 9 and the first threaded rod 9 on the upper end of the supporting rod 4 The threaded holes 10 are connected, and the wire hanging bracket 5 is located above the storage hole 3 .

[0018] In this embodiment, the wire-hanging bracket 5 is provided with an arc-shaped groove 6 for limiting the position of the optical fiber 13 with the wire.

[0019] In this embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com