Construction method for repairing bridge crack

A construction method and bridge technology, applied in bridges, bridge maintenance, bridge reinforcement, etc., can solve problems such as insufficient repair of cracks and difficulty in reaching hidden corners of repair materials, so as to reduce the generation of waste structural adhesive and improve the overall grouting Efficiency, the effect of prolonging the operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

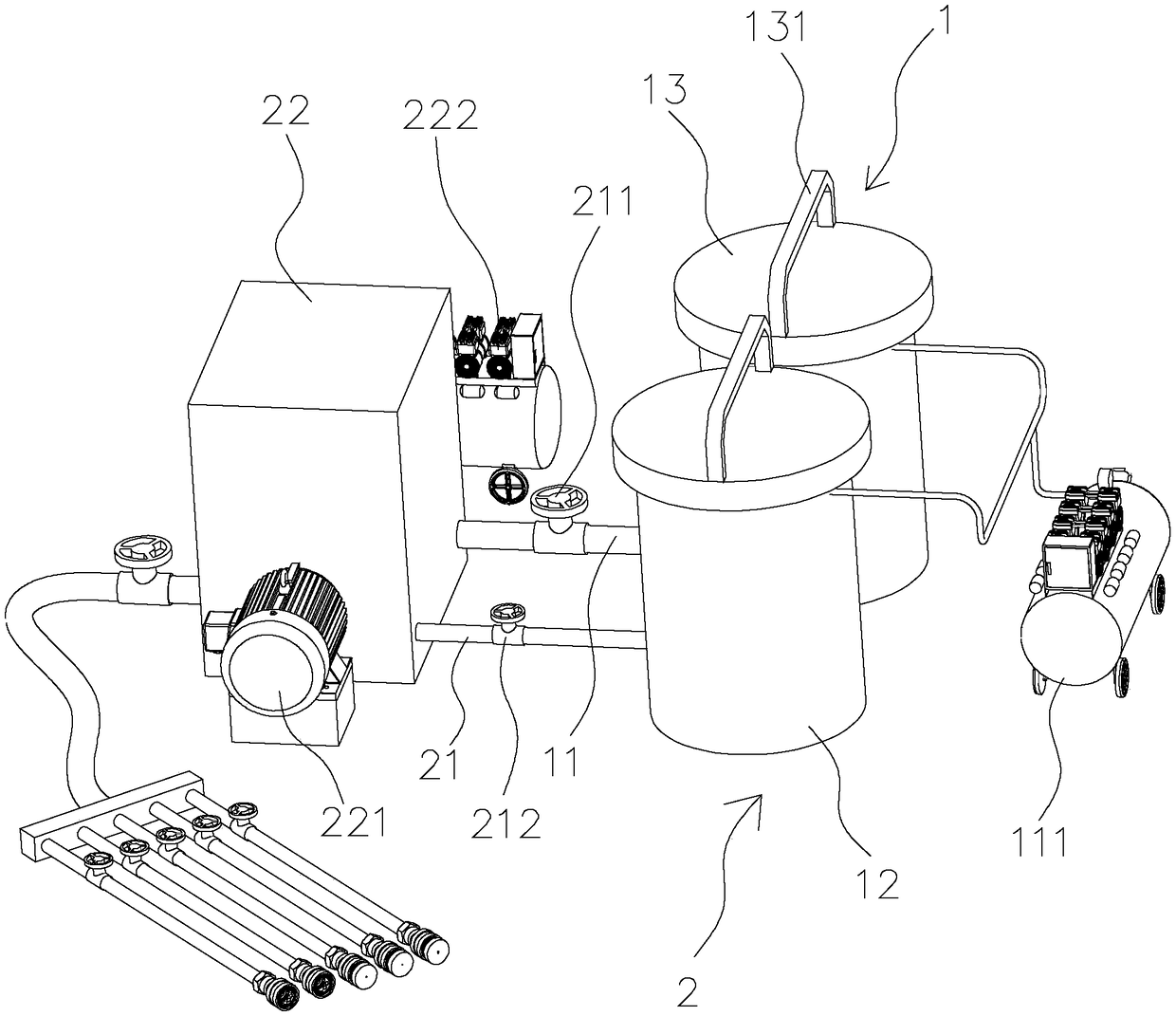

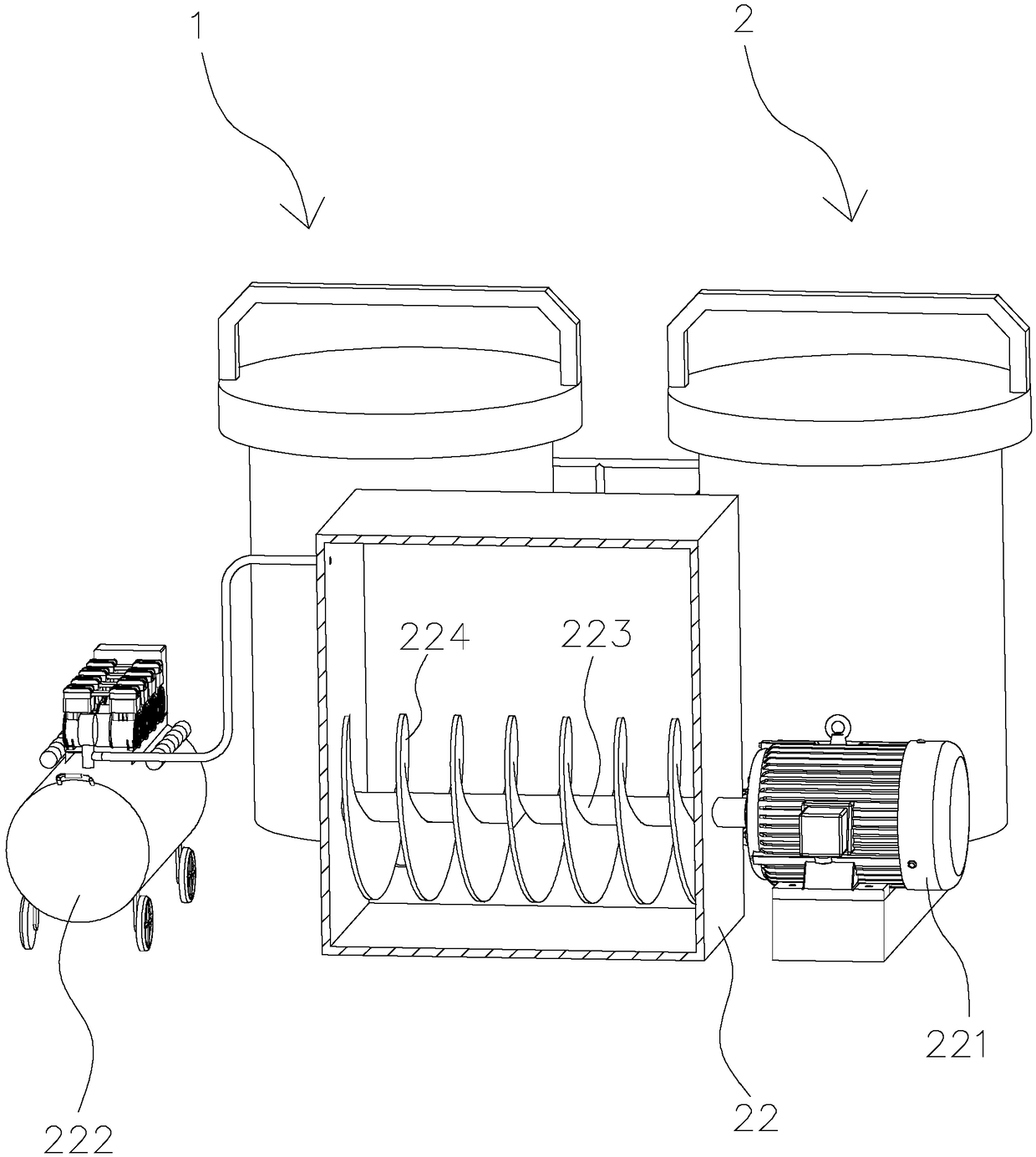

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0053] refer to figure 1 , is a construction method for repairing bridge cracks disclosed in the present invention. The glue injection device that needs to be used includes a first glue storage tank 1 and a second glue storage tank 2 that are set independently of each other. In this embodiment, the first glue storage tank 2 The glue storage tank 1 and the second glue storage tank 2 store glue A and glue B respectively, wherein glue A is an amino-terminated polyurethane elastic prepolymer, glue B is bisphenol A epoxy resin, glue A and glue B are mixed Composition of two-component crack glue for repairing cracks in bridges3. A first air compressor 111 is connected outside the first glue storage tank 1 and the second glue storage tank 2 .

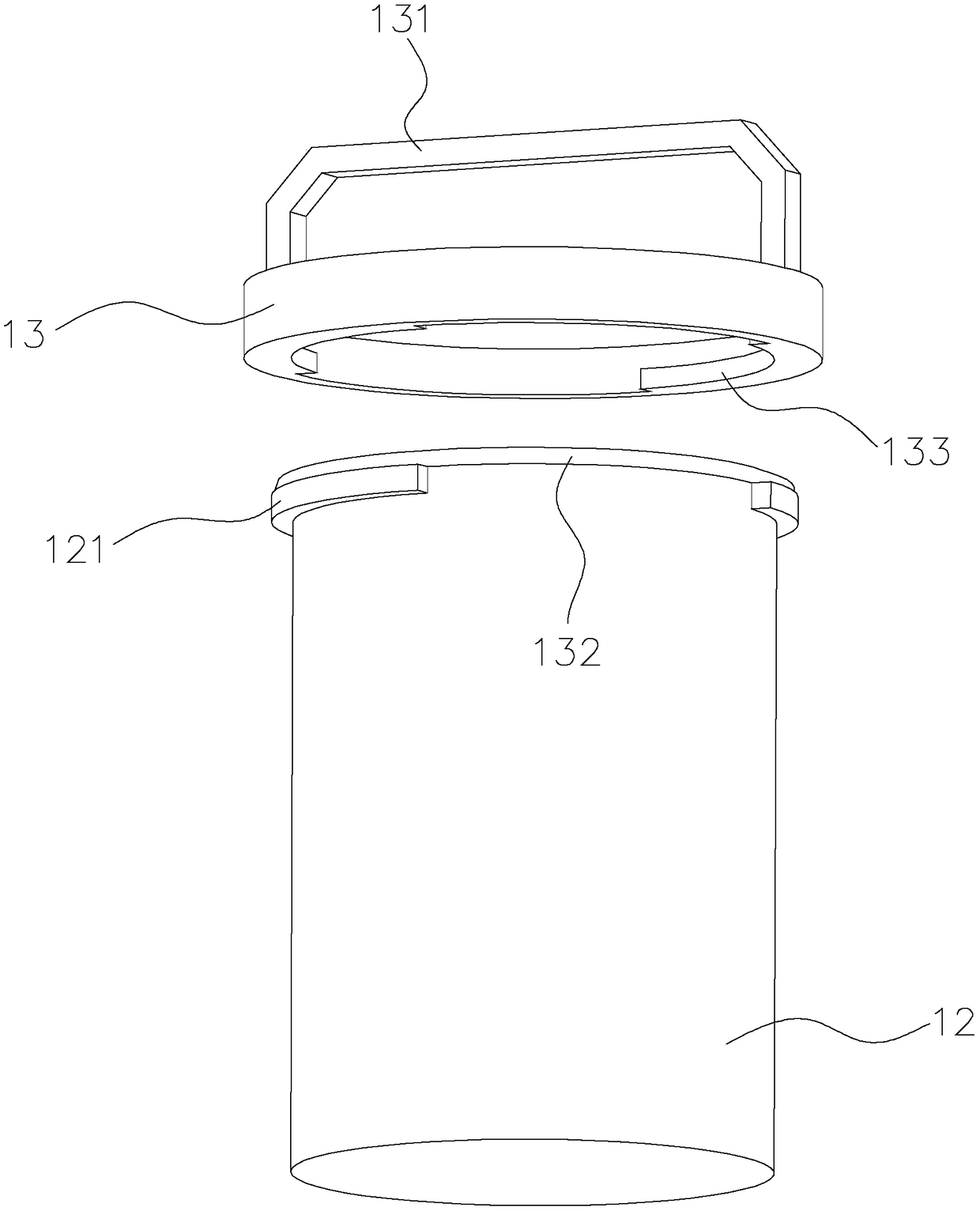

[0054] refer to figure 1 and figure 2 , the first glue storage tank 1 and the second glue storage tank 2 both include ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com