Novel steel plate beam and steel-concrete bond beam

A new type of steel plate beam technology, applied in the direction of load-bearing elongated structural members, girders, joists, etc., can solve problems such as difficulty in guaranteeing the deformation degree of welded steel plate beams, affecting the safety of bridge structures, and weak structural stress. , to achieve the effect of easy guarantee of welding quality, solving welding quality problems, and convenient processing and production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

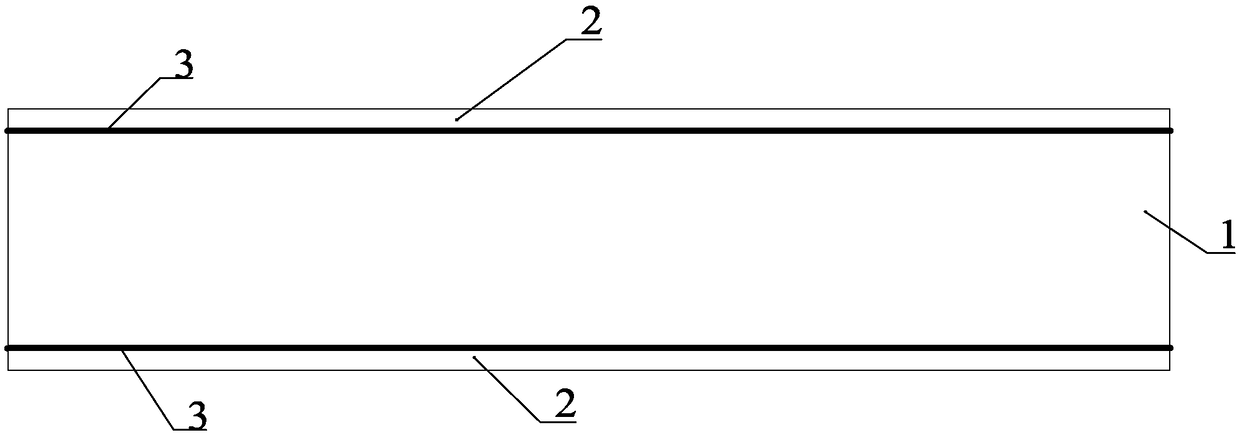

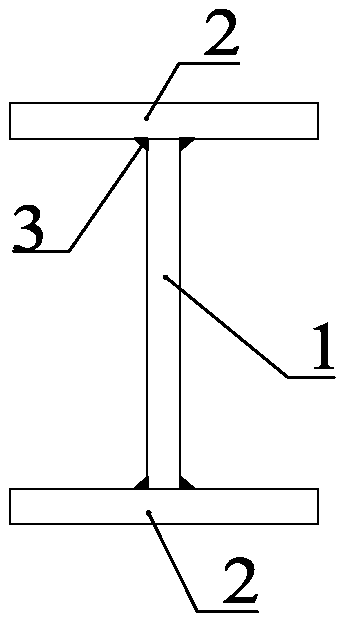

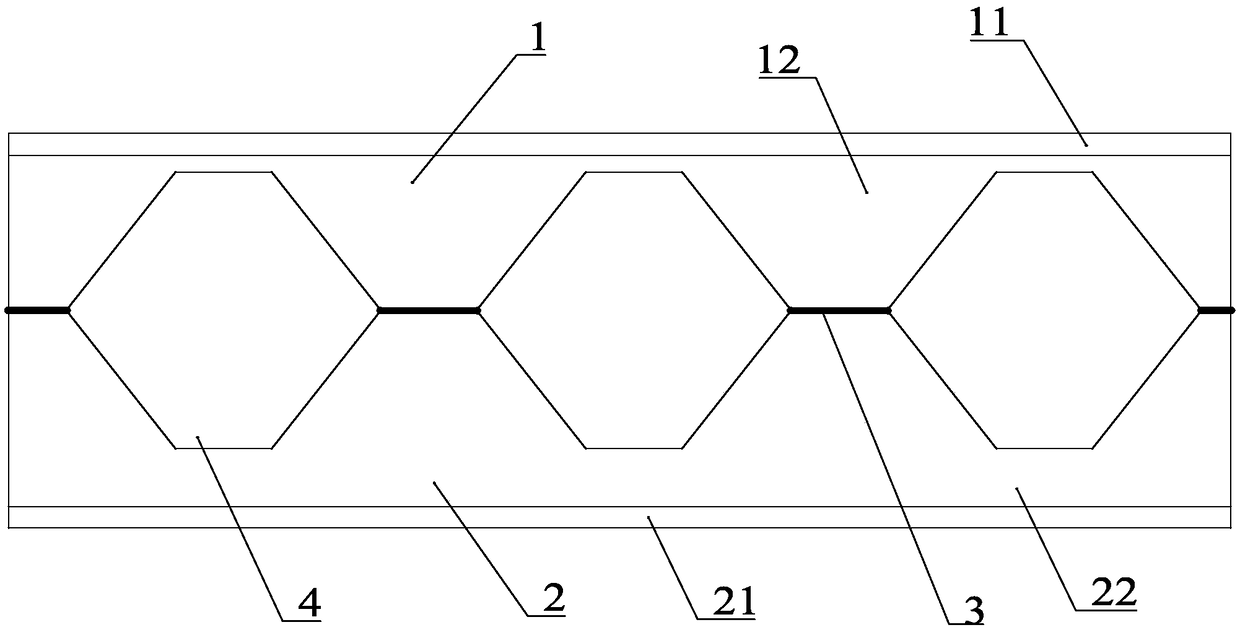

[0045] Such as Figure 3-Figure 8 As shown, a new type of steel plate girder includes a first assembled part 1 and a second assembled part 2, the first assembled part 1 includes a flange plate 11 and a web plate 12 integrally rolled and formed, and the first assembled part 1 The second assembling part 2 includes the flange plate 2 21 and the web 2 22 integrally rolled, and the web 12 and the web 2 22 are connected by a butt weld 3, and the butt weld 3 is fully melted Penetrating butt welds. Several hexagonal cavities 4 are formed between the first web 12 and the second web 22, and the cavities 4 are axisymmetric structures. Specifically, the side of the web one 12 away from the flange plate 11 is cut off by several cavity units 1 41, and the side of the web two 22 away from the flange plate two 21 is also cut off by several The second cavity unit 42 is cut off, and the openings of the first cavity unit 41 and the second cavity unit 42 are adapted to form the cavity 4 .

[0...

Embodiment 2

[0053] Such as Figure 11-Figure 12 As shown, a steel-concrete combined beam includes any one of the novel steel plate girders, and a concrete slab 6 covered on the new steel plate girder, and the new steel plate girder and the concrete slab 6 Connectors 7 are connected between them, thereby forming an integral structure that bears force together. The connecting piece 7 may be a shear nail or the like. At this time, not only the girder height of the new steel plate girder has been greatly increased to meet the construction requirements, but also the quality problem of the fillet welds has been solved. If the concrete slab is covered on it, the high tensile strength of the steel material, good ductility and concrete resistance will be fully utilized. The advantages of high compressive strength and high rigidity are very suitable for the field of bridge engineering.

Embodiment 3

[0055] Such as Figure 13 As shown, the difference between this embodiment and Embodiment 1 is that the distance between the cavity 4 and the first flange plate 11 is equal to the distance between the cavity 4 and the second flange plate 21, that is, when cutting, the The distance between the high cutting line 52 and the first flange plate 11 is equal to the distance between the low cutting line 53 and the second flange plate 21 , ie D1 = D2 . The size and shape of the first assembling part 1 and the second assembling part 2 formed by cutting in this way are convenient for assembling and processing.

[0056] When the girder height of the integrally rolled steel plate girder 1 is 1.2m, the processing method of the present invention can not only process a steel plate girder with a girder height greater than 1.2m, but can even process a steel plate with a girder height greater than or equal to 2m beam. In this embodiment, the beam height of the integrally rolled steel plate gir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com