Lubricating device for seawater hydraulic pump

A technology for lubricating devices and hydraulic pumps, which is applied to parts, pumps, and pump components of pumping devices for elastic fluids, and can solve problems such as poor lubrication performance, reduced service life of hydraulic pumps, and wear of internal parts of the power box. Problems, to achieve the effect of improving heat resistance and corrosion resistance, improving performance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

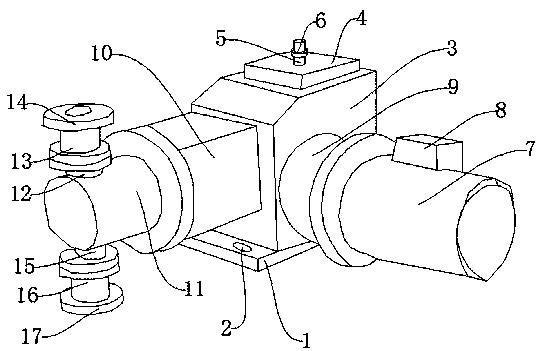

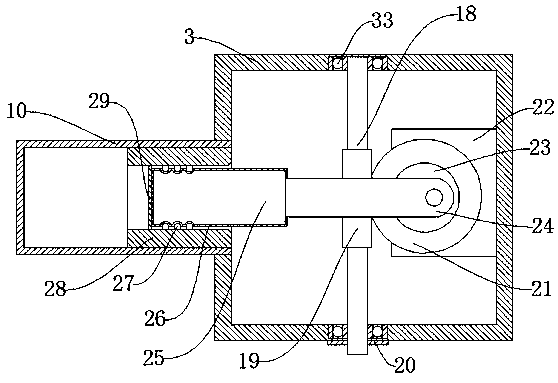

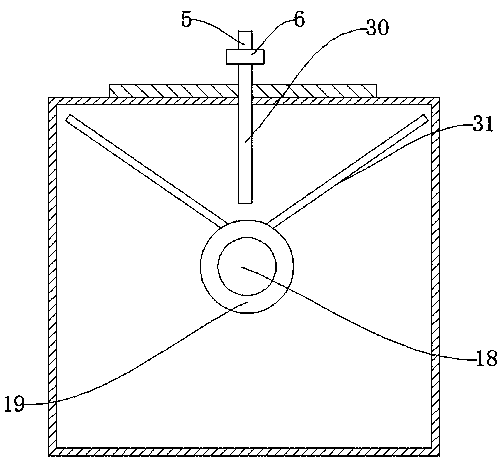

[0028] Such as Figure 1-Figure 5As shown, a seawater hydraulic pump lubricating device includes a support base 1, a power box 3, a bearing lubrication groove 31 and a plunger lubrication groove 32. The four corners of the support base 1 are formed with mounting holes 2, and the mounting holes 2 For installing this seawater hydraulic pump, the power box 3 is arranged above the support base 1, and the top sealing cover 4 is arranged above the power box 3, and the top sealing cover 4 realizes the control of the power The sealing of the box body 3, the top sealing cover plate 4 is provided with a lubricating oil filling pipe 5, the lubricating oil filling pipe 5 is used to inject lubricating oil into the power box body 3, the lubricating oil filling pipe 5 is An oil injection control valve 6 is provided, a power shaft seal cover 20 is provided on one side wall of the power bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com