Expansion bolt structure

A bolt structure and expansion bolt technology, applied in the field of fastening parts, can solve the problems of easy plastic failure of the material of the hole wall, the tightening force cannot be effectively improved, and the expansion force loss, etc., to overcome the small tightening force, Improve anchoring force and durability, and disperse the effect of anchoring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

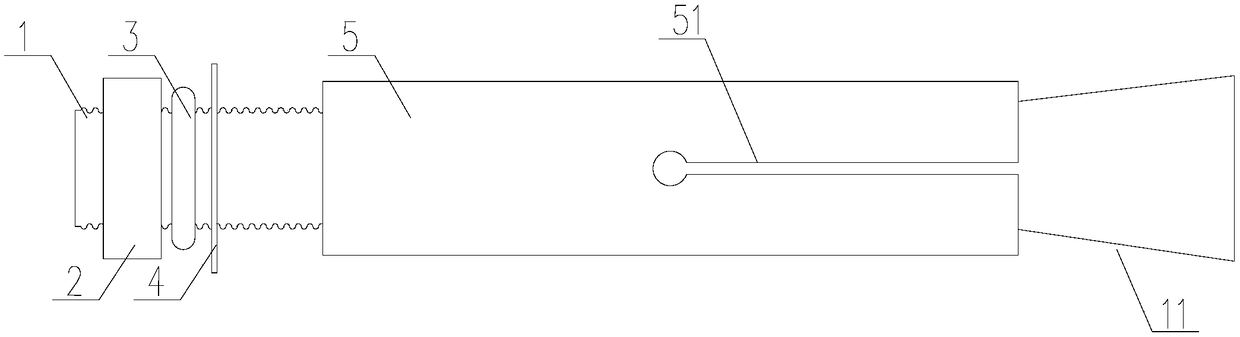

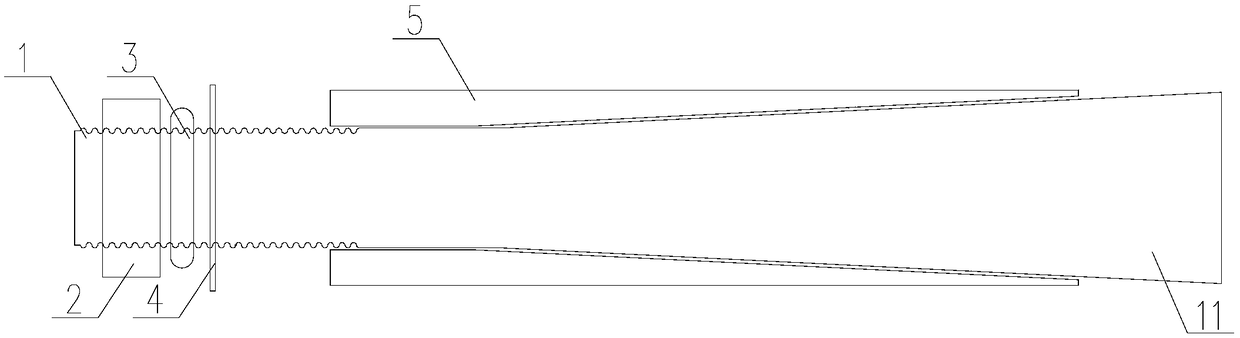

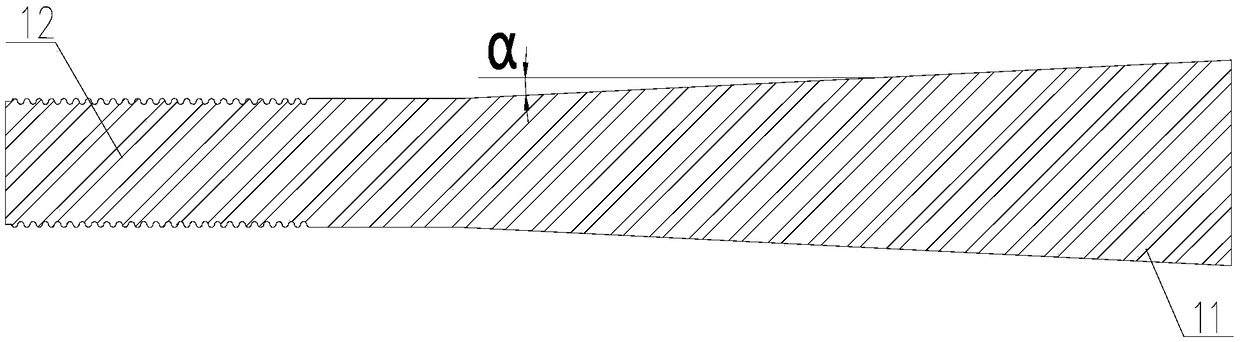

[0023] Such as Figure 1 to Figure 6 The shown expansion bolt structure includes a bolt body 1 composed of a threaded section 12 and an expansion bolt section 11. The expansion bolt section 11 is externally provided with an expansion shell structure 5, and the threaded section 12 is externally provided with a nut structure 2. The wall thickness of the expansion shell structure 5 is gradually thickened along the direction from the expansion bolt section 11 to the threaded section 12 and the inner wall surface of the expansion shell structure 5 is in close contact with the outer wall surface of the expansion bolt section 11 .

[0024] In the present invention, by coordinating the size of the vertebral body of the expansion bolt section 11 and the expansion shell structure 5, the expansion bolt section 11 and the expansion shell structure 5 are evenly stressed during the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com