Rotating self-pulling type framework gasket

A self-pulling, skeleton technology, used in gaskets, connecting components, mechanical equipment, etc., can solve the problems of increasing the difficulty of card processing, destroying the consistency of the card, and inconvenient use of skeleton gaskets, so as to improve product assembly quality and The effect of assembly efficiency, shortening production cycle and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

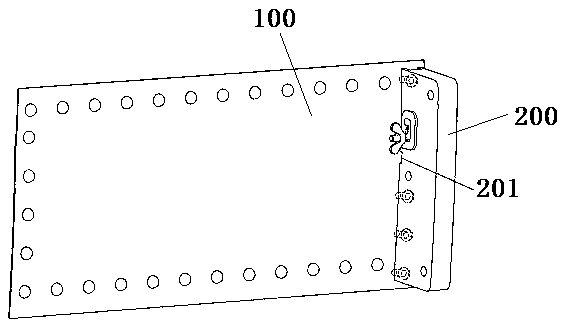

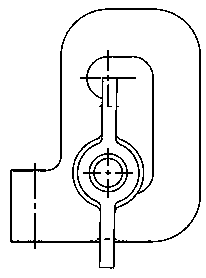

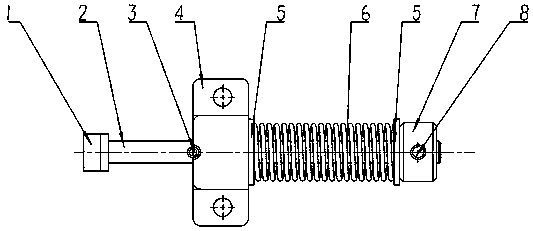

[0025] Example 1, see image 3 —— Figure 5 A rotating self-pull-type skeleton gasket shown includes a skeleton profile 1, a rod 2 and a positioning block 4. One end of the rod 2 is provided with a skeleton profile 1, and the other end is provided with a nut 7. The body of the rod 2 The pre-compression limiter is equipped with a positioning block 4, and the positioning block 4 includes an upper plate 41, a vertical plate 42 and a lower plate 43, and one side of the upper part of the lower plate 43 is provided with an upper plate 41 through the vertical plate 42, and the vertical plate 42 is provided with an upper plate 41. There are rod through holes, and the front and rear sides of the lower part of the lower plate 43 are respectively extended outwards to be provided with mounting ears 44, and the mounting ears 44 are provided with mounting holes 45, and the rod 2 is radially provided with pin holes, and the pin holes are provided with The cylindrical pin 3, the upper plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com