Optical fiber temperature sensor for measuring temperature field of transformer winding

A technology for the temperature of transformer windings and optical fibers, which is applied to thermometers, thermometers, measuring devices, etc. with physical/chemical changes. Influence and other issues, to avoid temperature strain crosstalk, improve service life and stability, ensure accurate measurement and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with accompanying drawing and embodiment:

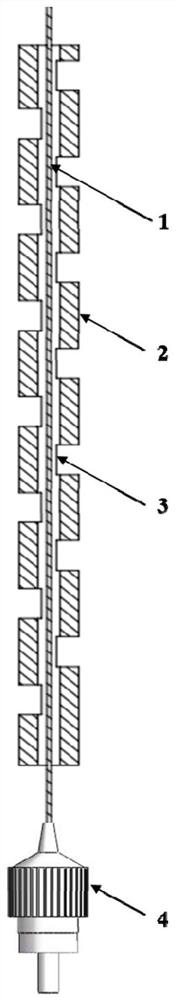

[0014] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of the present invention: an optical fiber temperature sensor for measuring the temperature field of a transformer winding, including a sensing optical fiber 1, one end of which is in a free state to ensure that the outer protective sleeve will not be bent during the laying process. Under tension, avoid temperature stress crosstalk and ensure accurate temperature measurement. The other end is an optical fiber connector 4, and the optical fiber connector 4 is plugged and connected with the optical fiber flange head on the through-board of the transformer box. The sensing optical fiber 1 is covered with a high temperature resistant protective sleeve 2, and the surface of the high temperature resistant protective sleeve 2 is provided with evenly distributed rectangular air groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com