Double cover sealing structure

A sealing mechanism and locking mechanism technology, applied in nuclear engineering, portable protective containers, etc., can solve the problems of radioactive gas leakage, affecting the opening and closing actions, air pressure changes of closed containers, etc., to simplify the driving mechanism and prevent pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific examples. The examples are implemented on the premise of the technical solutions of the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

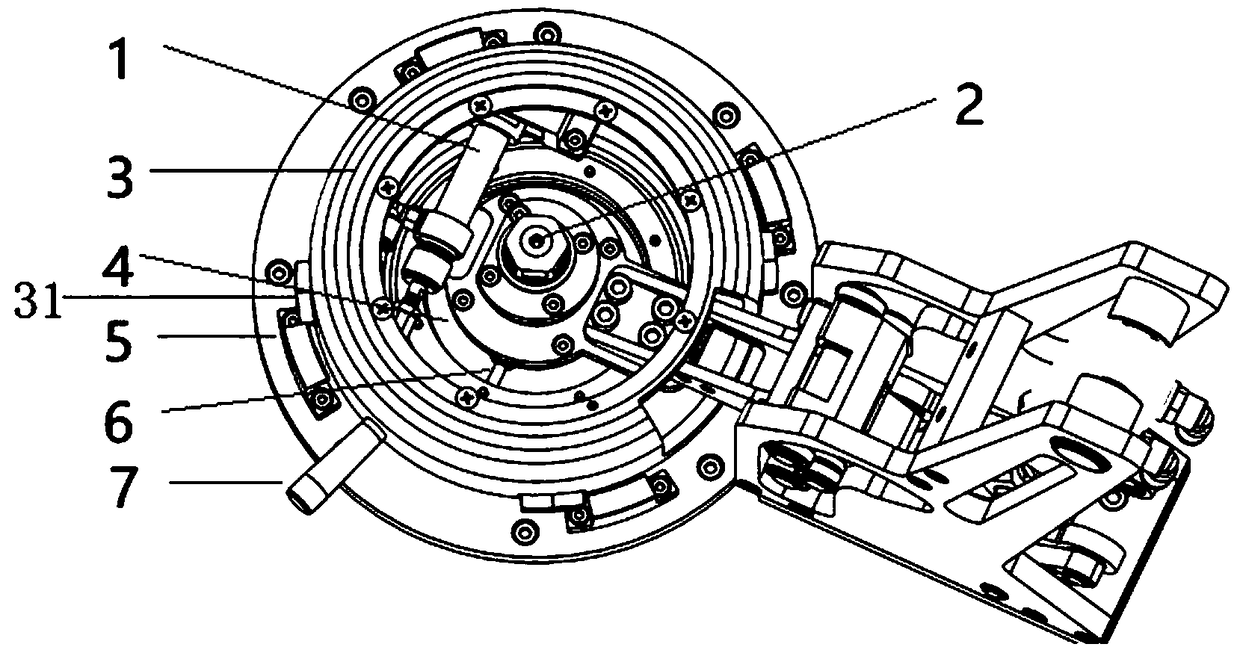

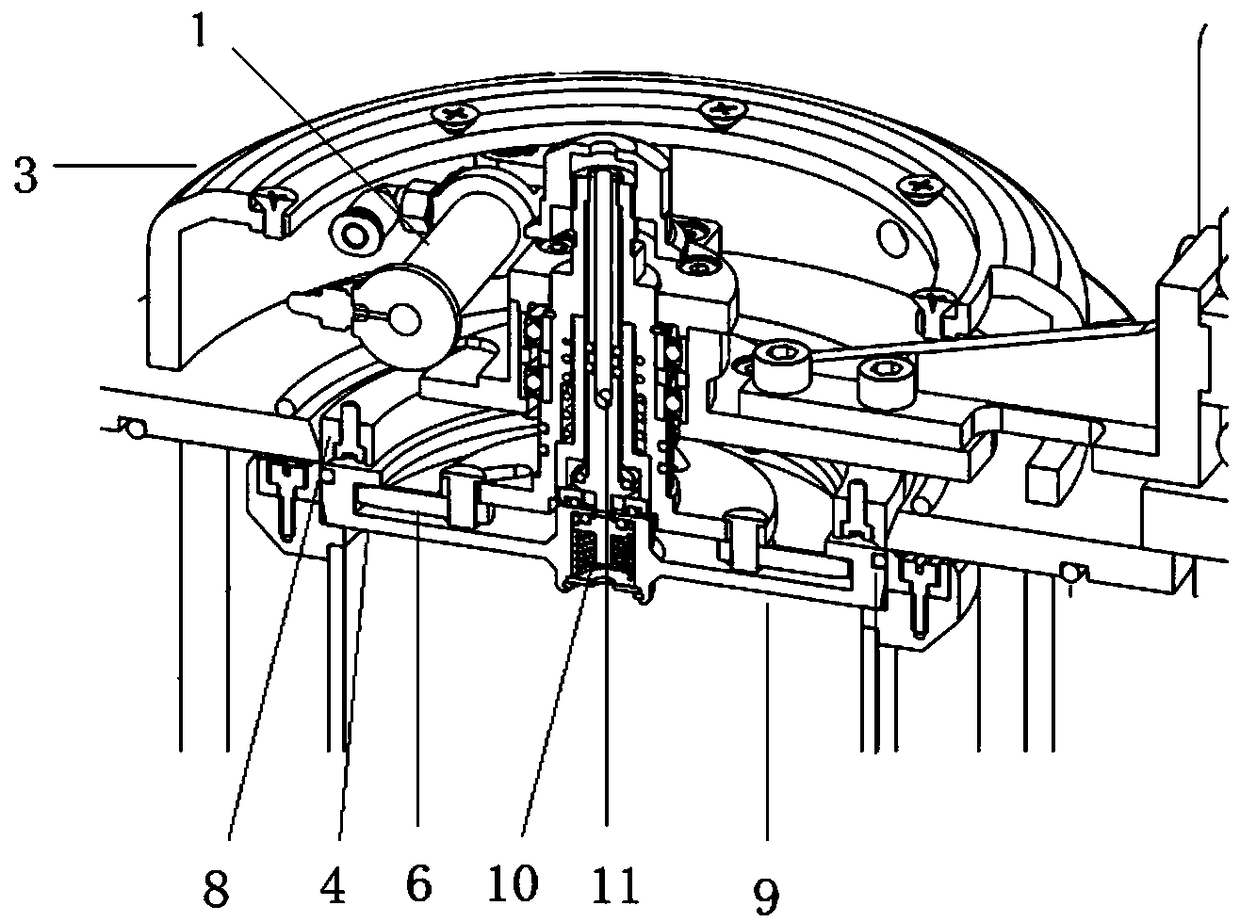

[0028] Such as figure 1 and figure 2 As shown, the double-cover sealing mechanism includes a shielding barrel, a shielding barrel cover, an airtight transfer barrel and an airtight transfer barrel cover 9;

[0029] The shielding lid is provided with a shielding lid locking ring 3, and the shielding lid locking ring 3 is fixedly provided with a shielding lid lock 31;

[0030] The upper end of the shielding barrel is provided with a barrel chamber locking block 5;

[0031] The shielding bucket lid locking ring 3 is rotated so that the shielding bucket lid lock 31 cooperates with the barrel ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com