Novel phase-change cooling and heating integrated structure for power batteries

A power battery, phase change cooling technology, applied in secondary batteries, electrochemical generators, circuits, etc., can solve problems such as aluminum plate heat pipes difficult to cylindrical power battery modules, achieve uniform processing process, reduce contact heat resistance and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better understand the present invention, the present invention will be further described below with reference to the accompanying drawings and embodiments.

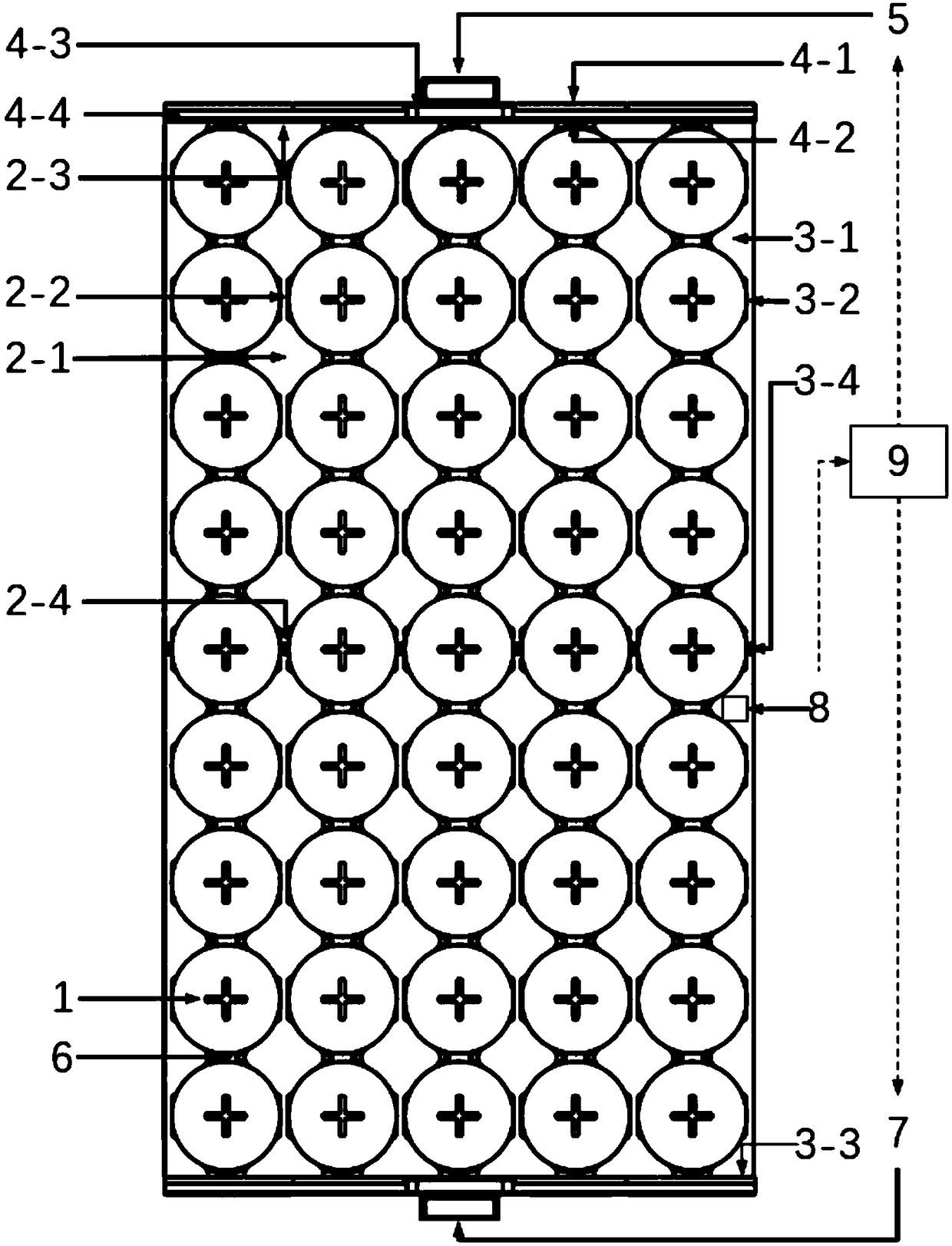

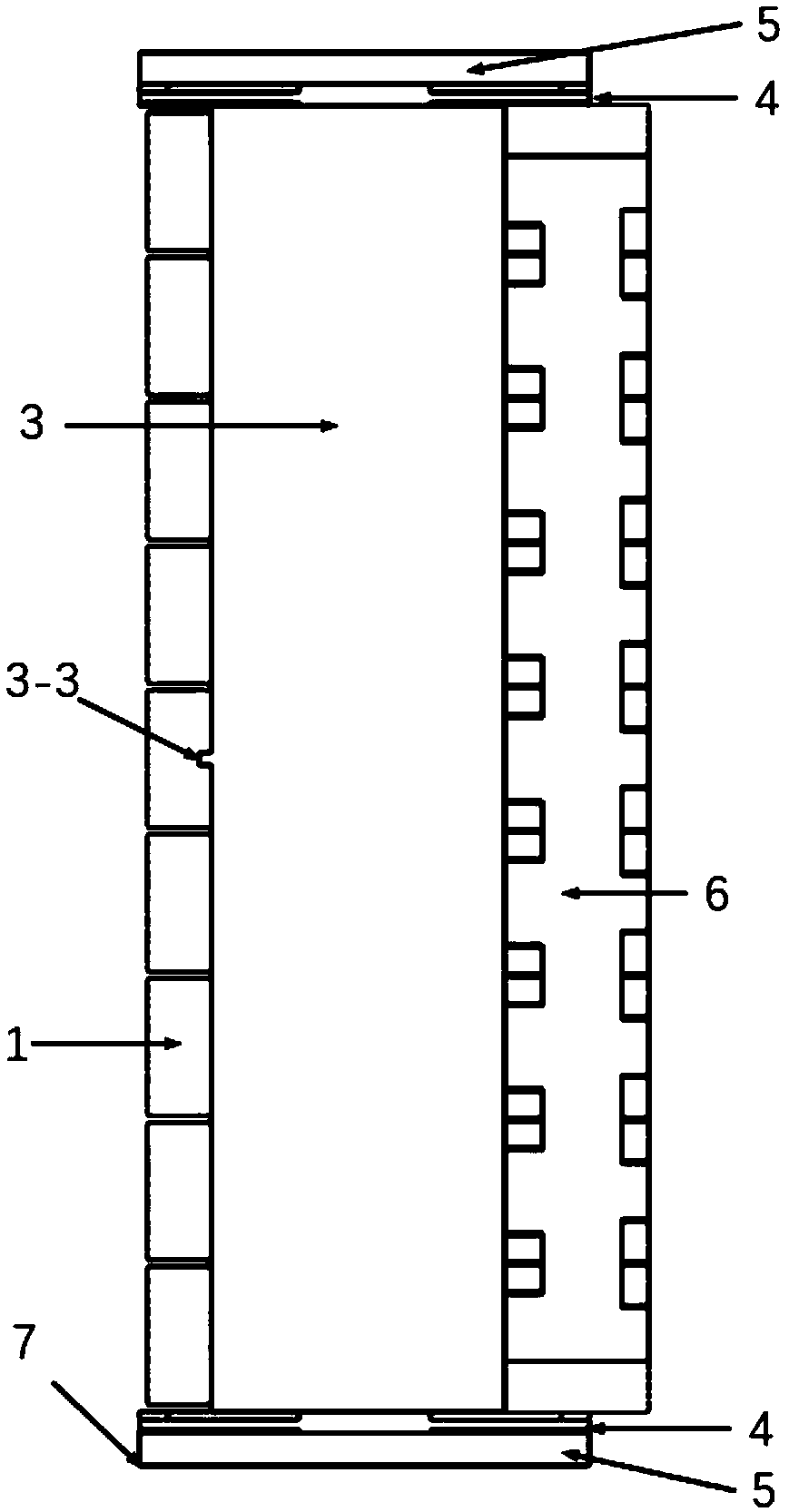

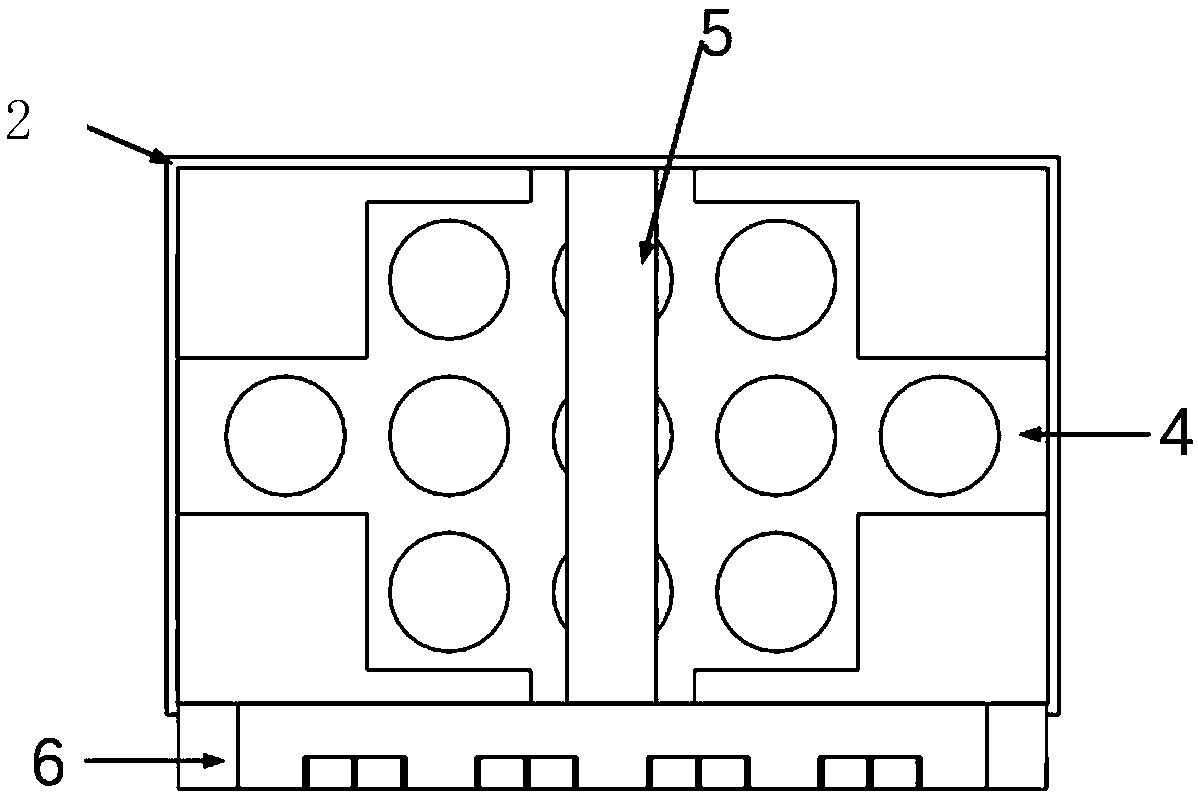

[0034] Such as Figure 1 to 4 As shown, a new phase-change cooling and heating integrated structure for power battery includes a power battery module fixture for array installation of cylindrical power battery pack 1, a temperature sensor 8 for monitoring the temperature of cylindrical power battery pack 1, In the control unit 9, the gaps on both sides of each column of the cylindrical power battery are filled with an inflatable type whose shape matches the outer contour of the cylindrical battery cell and closely fits the curved surface of each cylindrical power battery. An aluminum heat equalizing plate, the top of the power battery module is sequentially superimposed with an inflatable aluminum heat equalizing plate 4 and a heat exchange copper flat tube that are in heat transfer contact with the heat co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com