Noise-reducing wiper motor

A technology of wiper and motor housing, which is applied in the field of noise reduction and noise reduction wiper motors, which can solve the problems of short service life, large vibration, high noise, etc., and achieve the effects of long service life, reduced noise and problem of sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

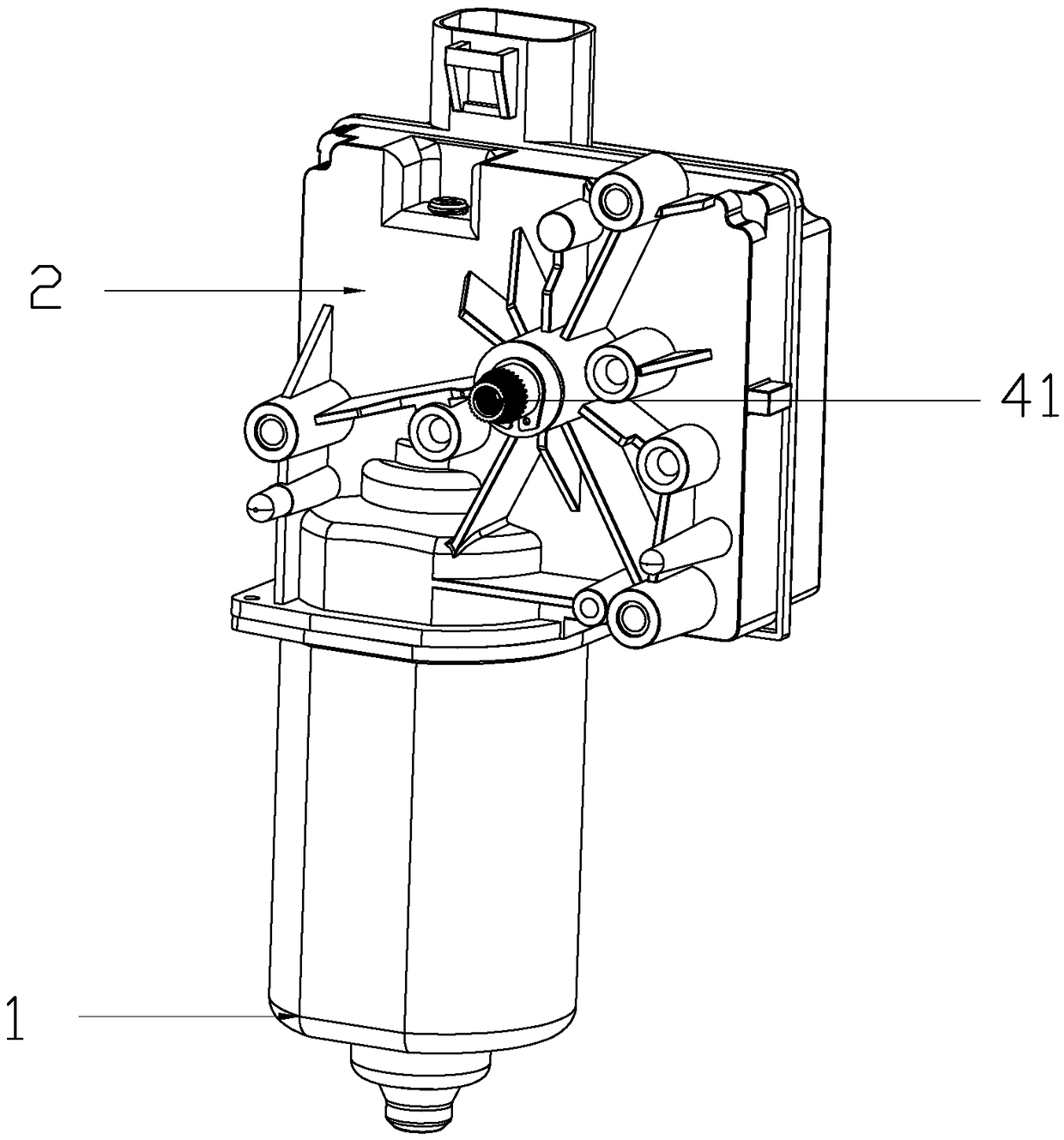

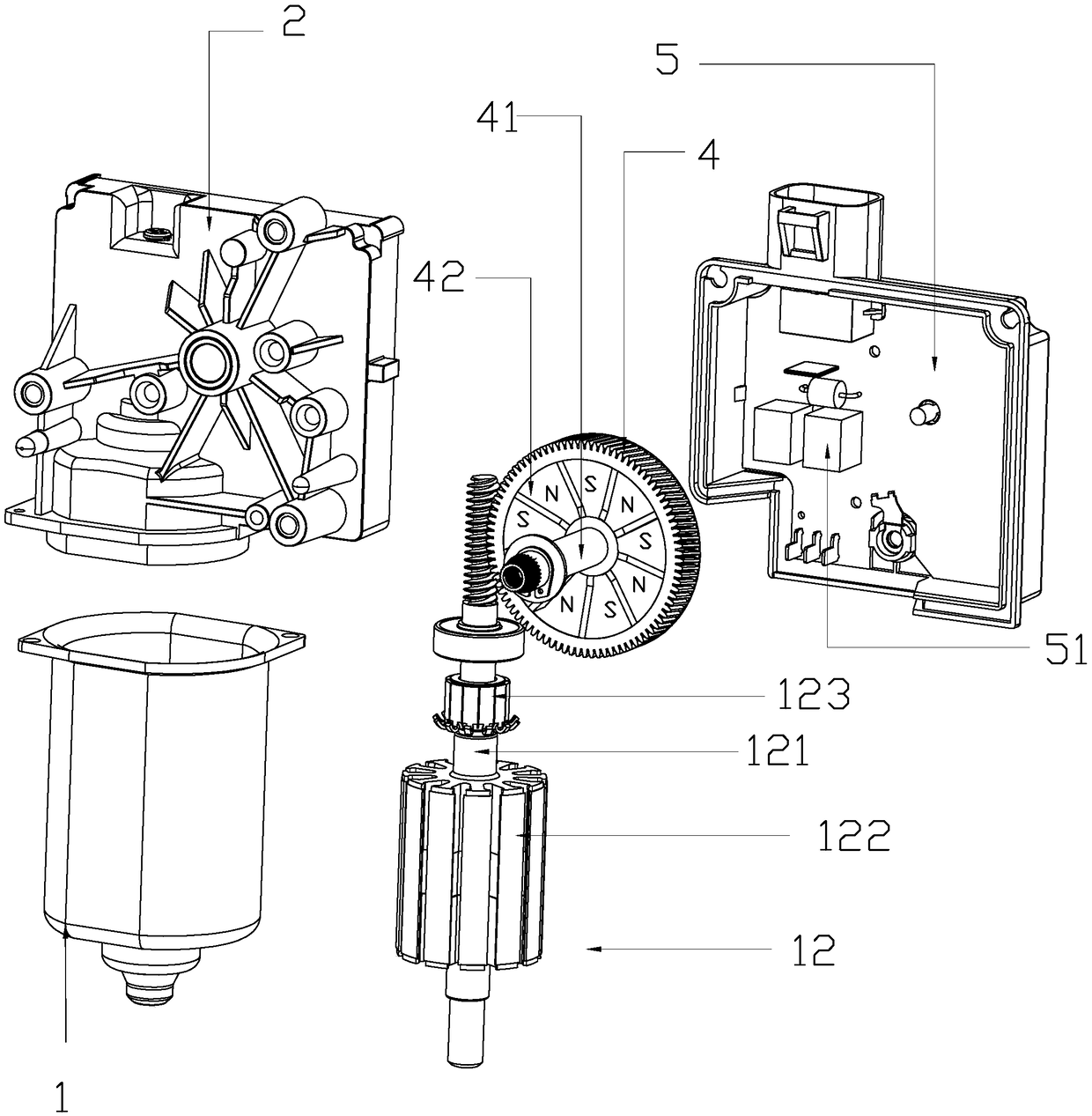

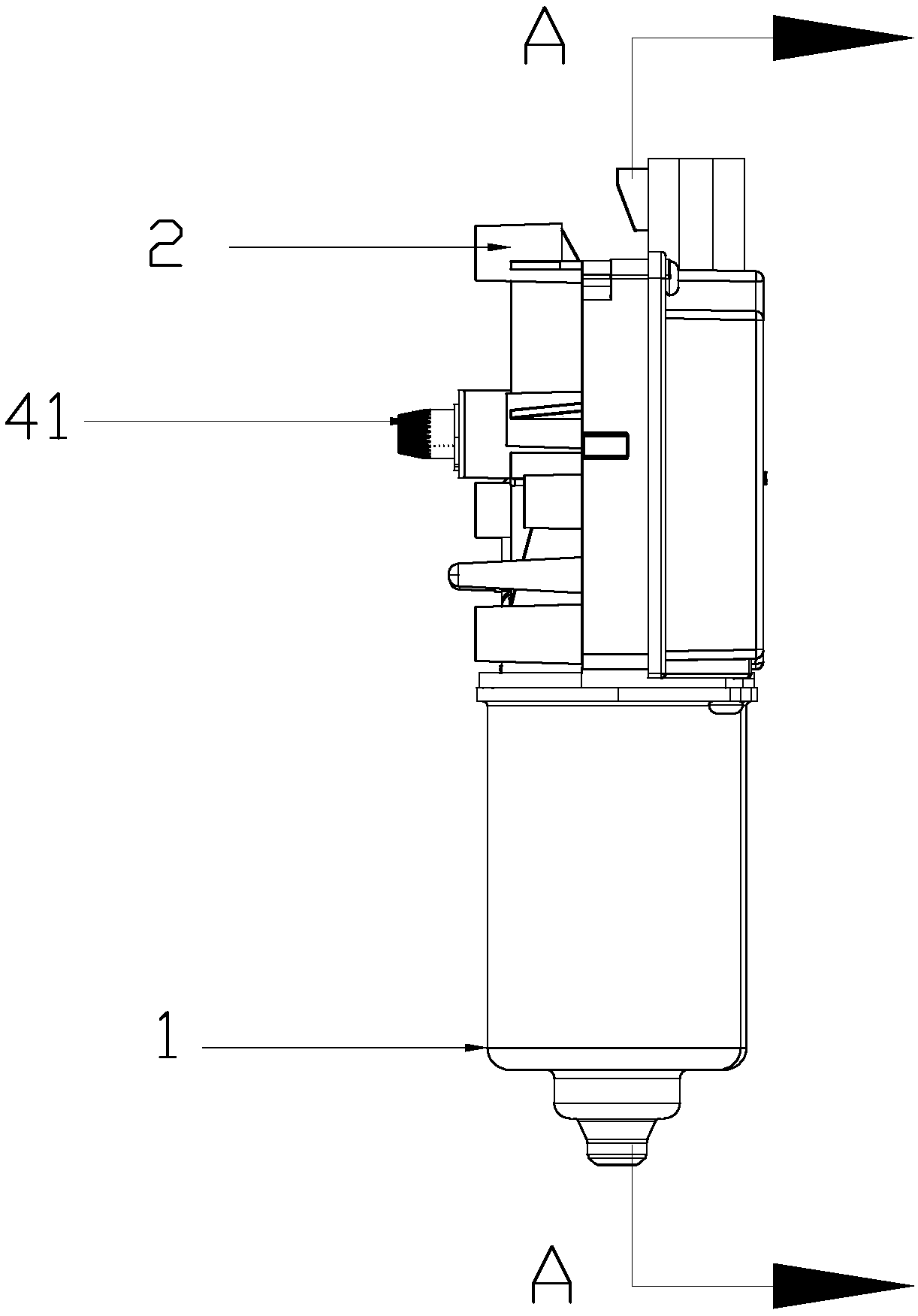

[0022] Such as Figure 1-Figure 7 As shown, a wiper motor with noise reduction and noise reduction includes a motor housing 1, a magnetic tile assembly 11 attached to the inner wall of the motor housing 1, an armature component 12 arranged in the motor housing 1, and The gear housing 2 interlocked with the motor housing 1, the brush component 3 attached to the inner wall of the gear housing 2, and the gear components arranged in the gear housing 2 are characterized in that the armature component 12 includes The rotor shaft 121 arranged in the motor housing 1, the winding 122 wound on the rotor shaft 121, and the commutator 123 arranged on the rotor shaft 121, the gear components include the The gear 4 in the middle, the circuit board 5 attached to the gear housing 2 corresponding to the gear 4, and the gear shaft 41 arranged on the gear 4 and linked with the gear 4, the gear part also includes an angle sensor, the The angle sensor includes a multi-pole magnetic block 42 arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com