A kind of method of using kimchi fermented liquid to prepare foot bath liquid

A technology of kimchi fermented liquid and foot bath liquid, which can be used in toiletry preparations, pharmaceutical formulas, cosmetic preparations, etc., can solve the problems of side effects, complicated process, expensive price, etc., and achieve rich natural nutrients, simple process, and non-toxic side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

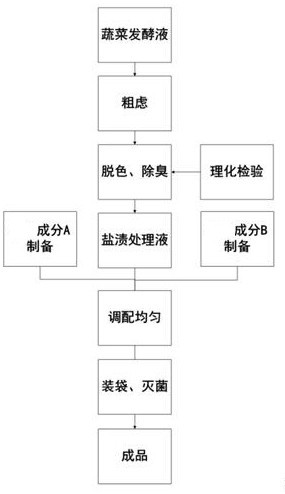

[0026] The invention discloses a foot bath containing kimchi fermented liquid, which is obtained by processing industrial kimchi fermented liquid. Among them, the processing method is as follows:

[0027] (1) Fermentation is mature, and salinity is 10-15% salted vegetable water (the pickle fermented liquid after the industry produces pickle) is collected in the regulating sedimentation tank, after standing to settle, its supernatant is carried out coarse filtration, Coarse filter with a mesh diameter of 0.15mm and a mesh width of 0.25mm to remove large particles of suspended impurities and residual vegetable leaves.

[0028] (2) decolorizing and deodorizing the vegetable fermented liquid obtained by the coarse filtration of step (1), that is, adding chitosan of 0.01‰ (in the mass meter of the vegetable fermented liquid obtained by the strained filtration) to the fermented liquid for flocculation, Flocculate and settle for 100 min, take the supernatant, and then add 3% activat...

Embodiment 2

[0034] The invention discloses a foot bath liquid containing industrial kimchi fermented liquid. The foot bath liquid contains the liquid after processing the industrial pickled vegetable fermented liquid (ie, salting treatment liquid), component A and component B. In terms of mass percentage, the saline treatment solution is 85%, component A is 14%, and component B is 1%. The specific preparation method is as follows:

[0035] (1) Collect fermented and mature salted vegetable water with a salinity of 10-15% in the adjustment sedimentation tank, after standing for precipitation, coarse filter the supernatant, the diameter of the coarse filter mesh is 0.15mm, and the mesh is wide 0.25mm to remove large particles of suspended impurities and residual vegetable leaves.

[0036] (2) decolorize and deodorize the vegetable fermented liquid obtained by rough filtering in step (1), add chitosan of 0.02‰ (in terms of the mass of the vegetable fermented liquid obtained by coarse filtrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com