Method for preparing nutritional wine brewed by fruit and millet

A production method and technology of nutritional wine, which are applied in the field of production of nutritional and health-care wine, can solve the problems of fruit juice and fruit aroma loss, influence on wine flavor and taste, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

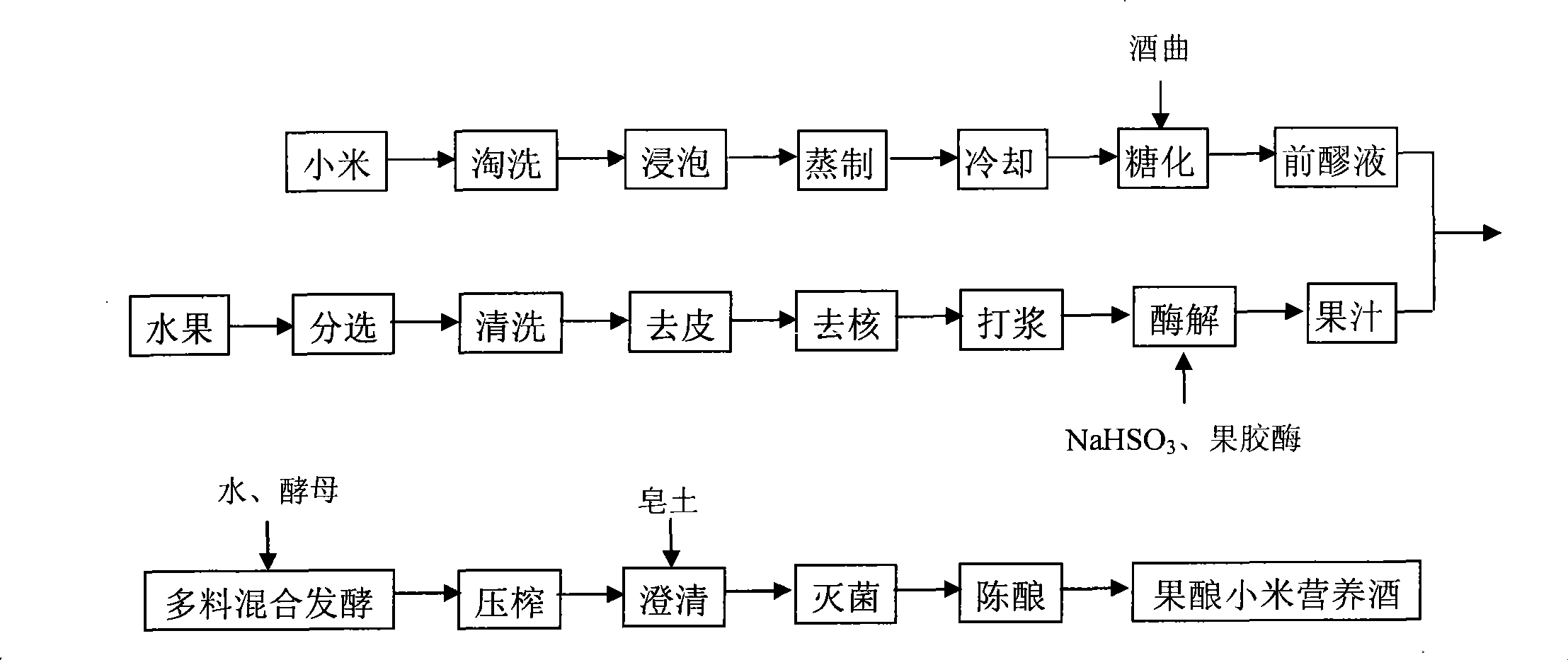

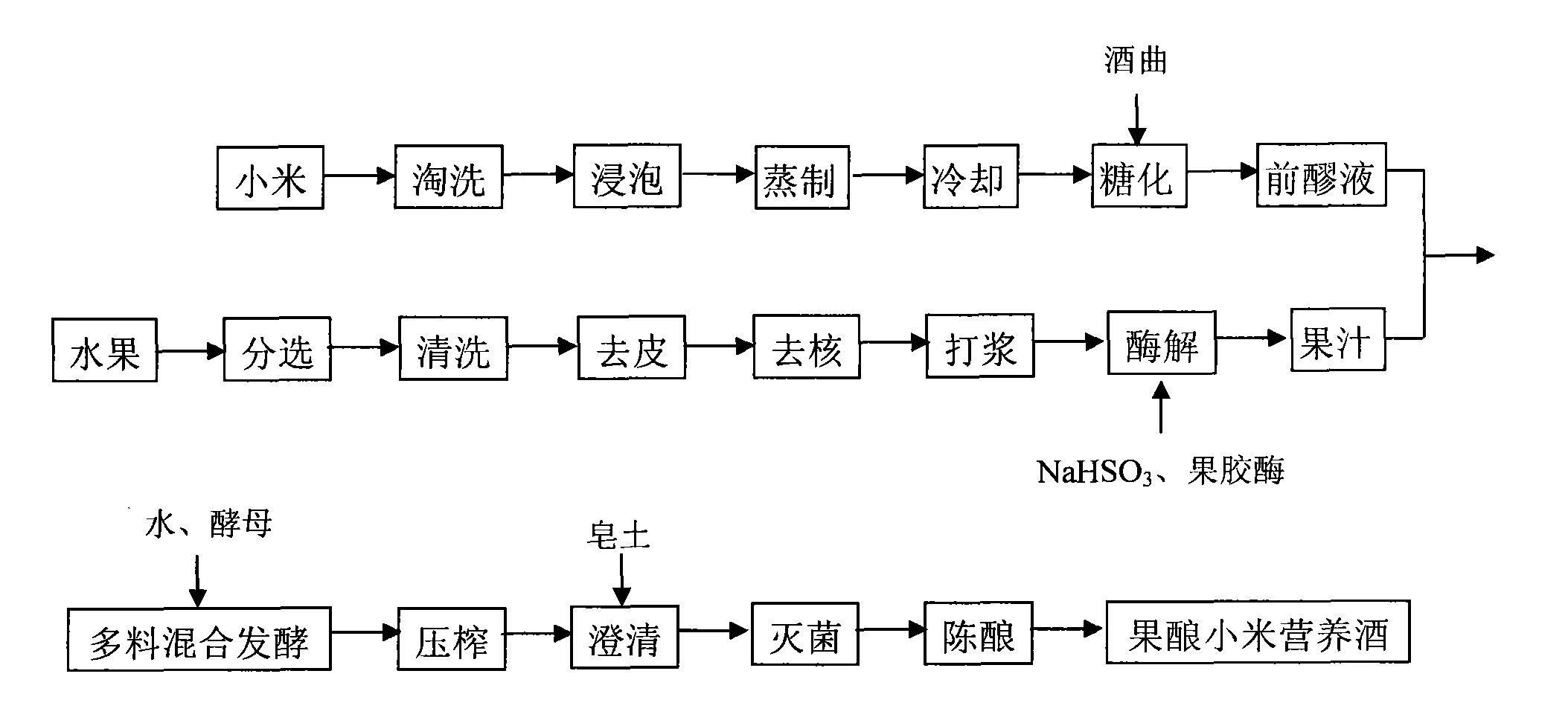

[0028] Such as figure 1 As shown, the preparation method of a fruit-stuffed millet nutritional wine provided by the present invention comprises the steps of fermenting millet and fruit as the main raw materials, pressing, clarifying, sterilizing, and aging the fermented materials to produce the resultant stuffed millet Nutritional wine, the millet and fruit are the main raw materials for fermentation, and the steps include:

[0029] After the millet is washed, water is added to the millet according to the volume ratio of millet and water of 1:2-5, soaked at room temperature for 10-20 hours, dehydrated, boiled, cooled by water and saccharified to make pre-mash;

[0030] Select ripe, plump and disease-free fruits, wash them, remove the peel and core, beat them into pulp in a beater, and then make juice through enzymatic hydrolysis;

[0031] According to the weight of 40 to 100 parts of dry millet, 60 to 100 parts of fruit, 0 to 40 parts of water and 0.1 to 0.5 parts of yeast, m...

Embodiment 2

[0037] In this example, after washing 100kg of glutinous millet, add water to the millet according to the volume ratio of millet and water of 1:3, and soak it at room temperature for 15 hours to make it fully absorb water and drench off the water; Add water to the millet at a volume ratio of 1:3, heat with steam, cook at 100°C for 30 minutes, pour the steamed millet with cold water to room temperature; Mix cooked millet and koji evenly, and saccharify at 30°C for 60 hours to obtain pre-mash;

[0038] Select 100kg of ripe, plump, disease-free pears, wash, peel, and remove cores, and add them to a beater to make pear pulp; 100 parts of pears, 0.005 parts of NaHSO 3 and 0.005 parts by weight of pectinase, pear pulp, NaHSO 3 Mix evenly with pectinase, enzymolyze at 30°C for 10 hours; heat to 100°C to inactivate the enzyme for 15 minutes, cool to make pear juice.

[0039] According to the weight of 100 parts of dry millet, 100 parts of pears, 40 parts of water and 0.5 parts of ye...

Embodiment 3

[0042] In this embodiment, 50Kg japonica millet and 50Kg glutinous millet are mixed evenly. After washing, water is added to the millet according to the volume ratio of millet and water as 1:4, and soaked at room temperature for 18 hours to make it fully absorb water and drain the water; Move to a steamer, add water to the millet according to the volume ratio of millet and water of 1:4, heat with steam, heat to 100°C and cook for 20 minutes, pour the steamed millet with cold water to room temperature; press 100 parts of dry millet and 0.5 parts of distiller's yeast by weight, mix cooked millet and distiller's yeast evenly, and saccharify at 32°C for 48 hours to obtain pre-mash;

[0043] Select 80kg of ripe, plump and disease-free fresh dates, wash them, remove the pits, and beat them into date pulp in a beater, according to 80 fresh dates and 0.015 parts of NaHSO 3 And 0.015 parts by weight of pectinase, jujube pulp, NaHSO 3 Mix evenly with pectinase, enzymolyze at 35°C for 25 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com