Method for preparing low-sugar coarse cereal nutritional wine

A technology for nutritious wine and miscellaneous grains, which is applied in the field of producing low-sugar nutritional health-care wine, can solve the problems of difficulty in satisfying the nutrition of various miscellaneous grains, high sugar content, not meeting the needs of low-sugar nutrition, etc., and achieves excellent nutritional and health care effects and rich nutrition. , flavor and mouthfeel harmonized soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

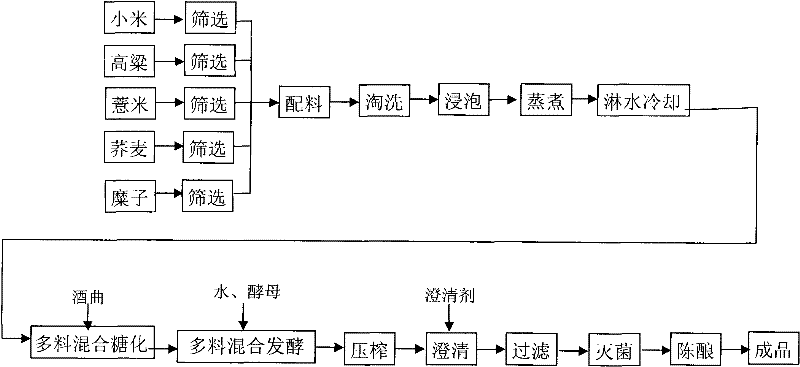

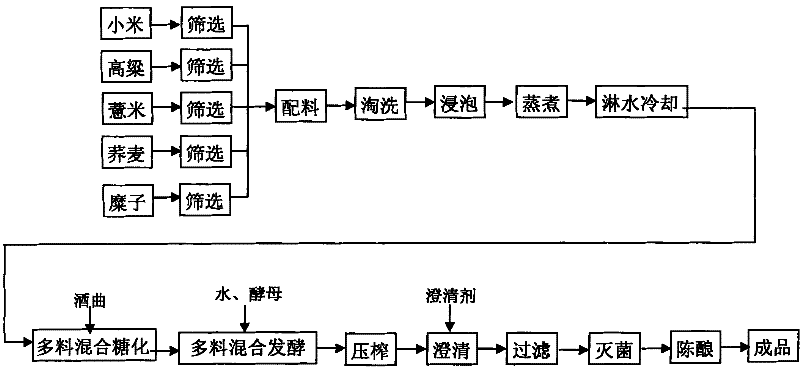

Image

Examples

Embodiment 1

[0034] Example 1 Coarse grain low-sugar nutritional wine

[0035] (1) Screen millet, buckwheat, sorghum, barley and broomcorn respectively to remove impurities, mix 60 parts of millet, 10 parts of buckwheat, 10 parts of sorghum, 10 parts of job's tears and 10 parts of broomcorn by weight, mix well, and then wash Wash, add water to the miscellaneous grains according to the ratio of miscellaneous grains to water (1:3 (W / W), soak at room temperature for 10 hours, move to a pot, cook at 90°C for 60 minutes, pour the steamed miscellaneous grains with cold water to room temperature .

[0036] (2) Based on the weight of 100 parts of miscellaneous grains, add 0.5 part of distiller's yeast to the cooked miscellaneous grains, stir evenly, and carry out multi-material mixed saccharification at 33°C for 24 hours. Add 0.01 part of yeast to the saccharified material based on the weight of 60 parts of miscellaneous grains, mix evenly, carry out multi-material mixed fermentation at 16°C, and...

Embodiment 2

[0038] Example 2 Coarse grain low-sugar nutritional wine

[0039] (1) Screen millet, buckwheat, sorghum, barley and broomcorn respectively to remove impurities, mix 10 parts of millet, 10 parts of buckwheat, 10 parts of sorghum, 60 parts of job's tears and 10 parts of broomcorn by weight, mix well, and then wash Wash, add water to the miscellaneous grains according to the ratio of miscellaneous grains to water 1:1 (W / W), soak at room temperature for 30 hours, move to a steamer, and cook at 125°C for 10 minutes, pour the steamed miscellaneous grains with cold water room temperature.

[0040] (2) Add 0.5 parts of distiller's yeast to the cooked miscellaneous grains by weight of 60 parts of miscellaneous grains, stir evenly, and carry out multi-material mixed saccharification. Perform multi-material mixed saccharification at 27° C. for 36 hours. Add 0.05 part of yeast to the saccharified material based on the weight of 100 parts of miscellaneous grains, mix evenly, carry out mul...

Embodiment 3

[0042] Example 3 Miscellaneous grains and low-sugar nutritional wine

[0043] (1) Screen millet, buckwheat, sorghum, barley and broomcorn respectively to remove impurities, mix 15 parts of millet, 40 parts of buckwheat, 15 parts of sorghum, 15 parts of job's tears and 15 parts of broomcorn millet by weight, mix well, and then wash Washing, add water to the miscellaneous grains according to the ratio of miscellaneous grains to water 1:1.5 (W / W), soak at room temperature for 25 hours, move to a steamer, cook at 95°C for 45 minutes, and pour the steamed miscellaneous grains with cold water room temperature.

[0044] (2) According to the weight of 90 parts of miscellaneous grains, add 0.2 parts of distiller's yeast to the cooked miscellaneous grains, stir evenly, and carry out multi-material mixed saccharification at 27°C for 36 hours. Add 0.05 part of yeast to the saccharified material based on the weight of 70 parts of miscellaneous grains, mix evenly, carry out multi-material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com