Method for screening copper from copper-containing sulfur concentrates low in copper grade

A concentrate, copper-sulfur technology, applied in flotation, solid separation and other directions, can solve the problem of not being able to comprehensively recover copper, and achieve the effects of improving sorting indicators, thorough drug removal, and improving recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

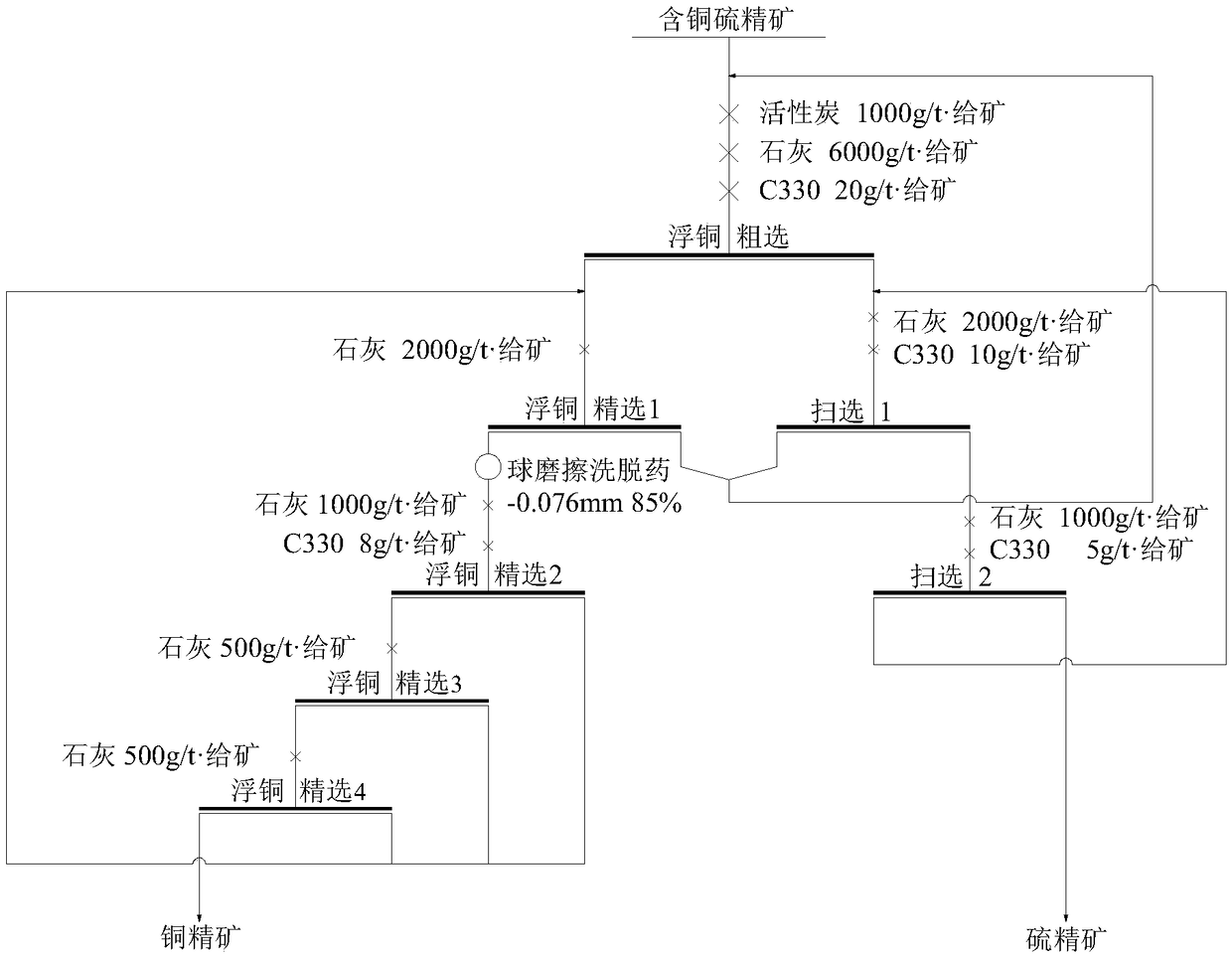

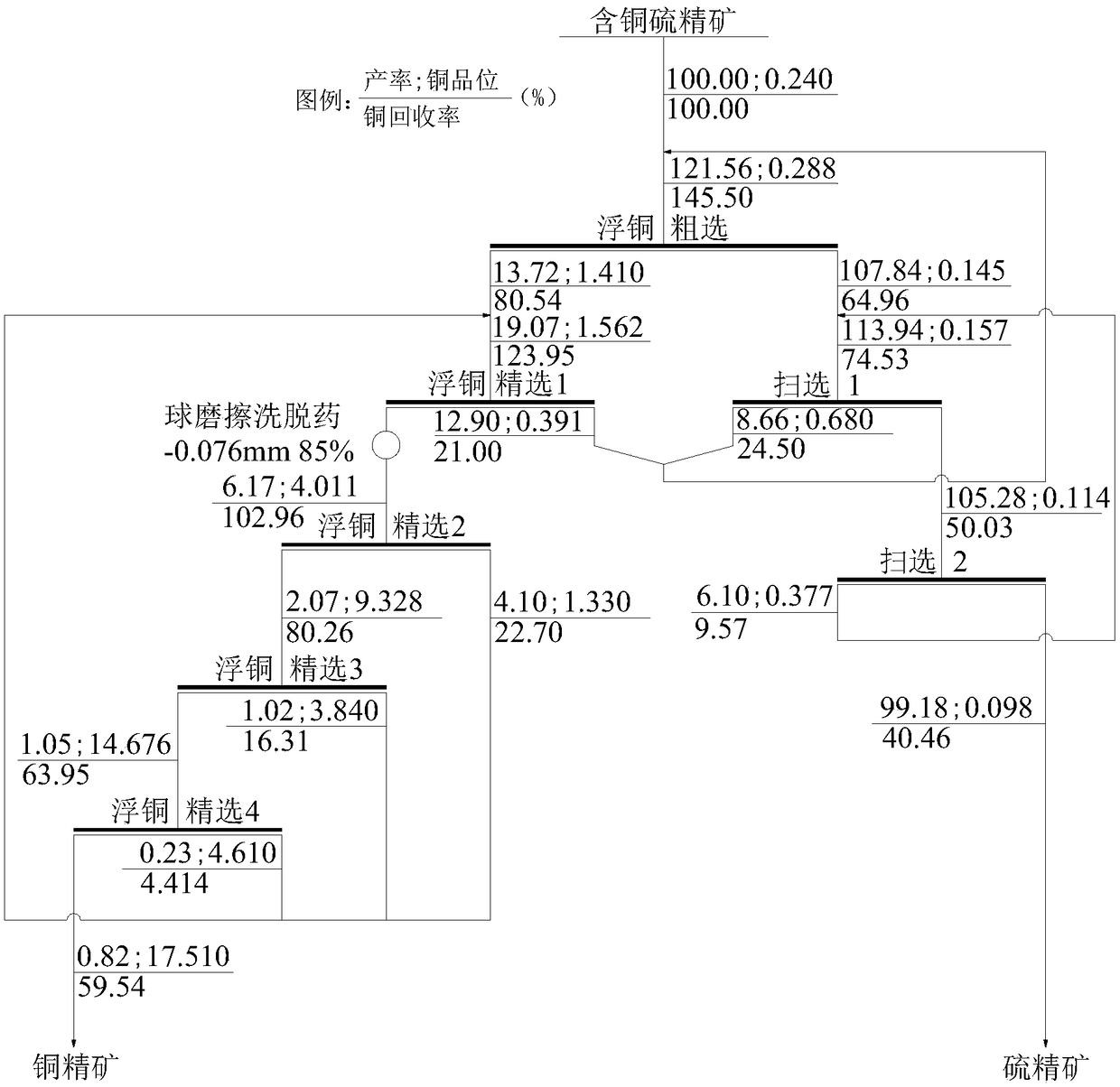

[0027] In order to further describe the present invention, a method for separating copper from a copper-containing sulfur concentrate with extremely low copper grade will be further described in detail below in conjunction with the accompanying drawings and examples.

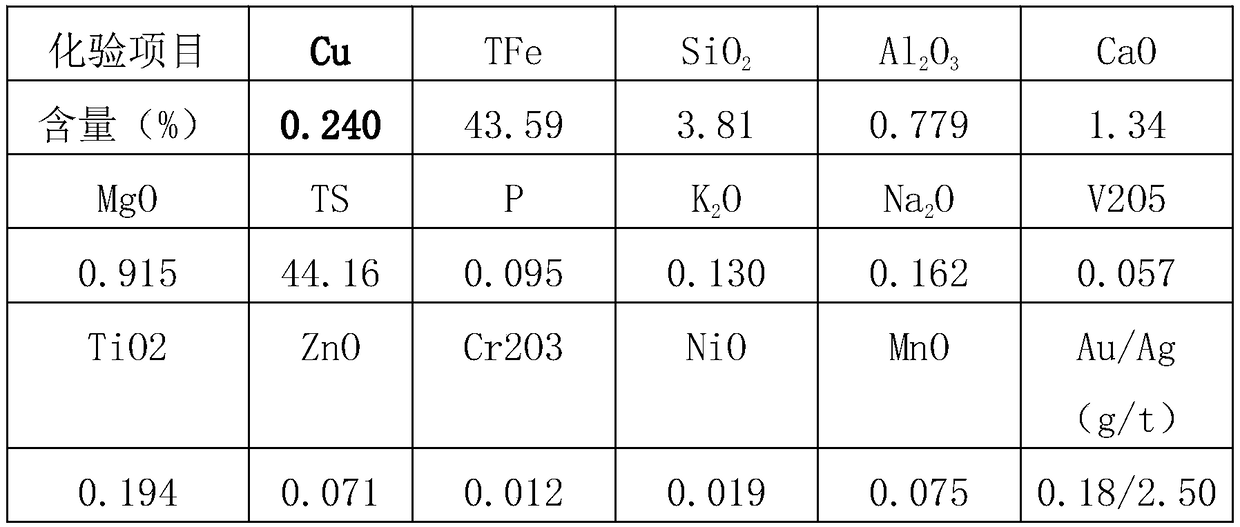

[0028] The extremely low-grade copper-containing sulfur concentrates treated in the examples were taken from an iron ore dressing plant in Anhui. The results of chemical multi-element analysis and copper phase analysis are shown in Table 1 and Table 2, respectively.

[0029] Table 1 Chemical multi-element analysis results of copper-bearing sulfur concentrates (%)

[0030]

[0031] Table 1 shows that in addition to sulfur and iron in sulfur concentrate, Cu also has comprehensive recovery value (gold and silver are enriched in copper concentrate).

[0032] Table 2 Phase analysis results of copper in copper-bearing sulfur concentrate (%)

[0033] Mineral phase name

Copper content in copper phase

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap