Quartz sand flotation agent removal method

A technology of quartz sand and flotation, which is applied in the direction of silica, silicon oxide, etc., can solve the problems of affecting product indicators, unclean cleaning, and difficult cleaning and cleaning, so as to avoid secondary pollution, remove drugs thoroughly, and speed up the cleaning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

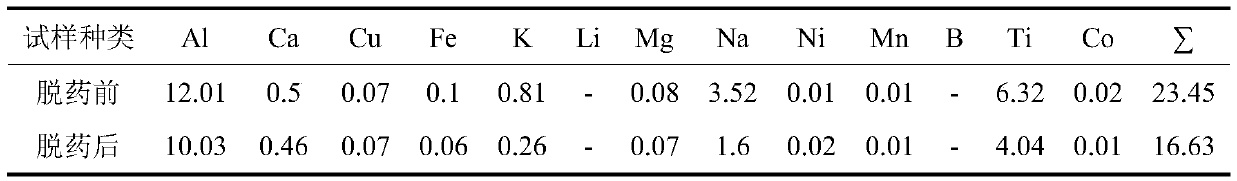

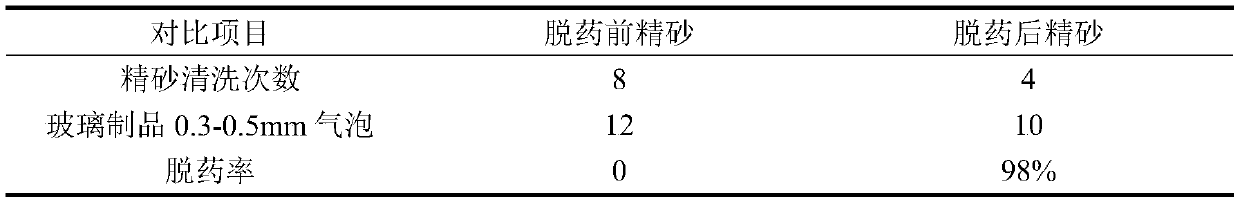

Embodiment 1

[0033] A method for removing drugs by quartz sand flotation, comprising the following steps:

[0034] (1) Dosing and scrubbing: Take the quartz sand after flotation, the particle size of the quartz sand is 0.1-0.2mm, add the mixed agent, the mass ratio of the quartz sand to the mixed agent is 1:2, and the mixed agent includes ammonia water and absolute ethanol , the mass ratio of ammonia water to absolute ethanol is 1:1, scrubbing, the scrubbing speed is 1000r / min, the scrubbing time is 30min, centrifuged until the moisture content of the quartz sand is less than 8%;

[0035] (2) Cleaning with hot pure water: Add hot pure water to the centrifuged quartz sand in step (1) to stir and clean, the temperature of pure water is 80°C, the conductivity of pure water is less than 2 μs / cm, and the rotating speed during stirring and cleaning is 100r / min, stirring time 5min, centrifuge until the moisture content of the quartz sand is less than 8%;

[0036] (3) Calcination: calcining the c...

Embodiment 2

[0041] A method for removing drugs by quartz sand flotation, comprising the following steps:

[0042] (1) Dosing and scrubbing: Take the quartz sand after flotation, the particle size of the quartz sand is 0.2-0.3mm, add the mixed agent, the mass ratio of the quartz sand to the mixed agent is 1:2, and the mixed agent includes ammonia water and absolute ethanol , the mass ratio of ammonia water to absolute ethanol is 1:2, scrubbing, the scrubbing speed is 1200r / min, the scrubbing time is 20min, centrifuged until the moisture content of the quartz sand is less than 8%;

[0043] (2) Cleaning with hot pure water: Add hot pure water to the centrifuged quartz sand in step (1) to stir and clean, the temperature of pure water is 80°C, the conductivity of pure water is less than 2 μs / cm, and the rotating speed during stirring and cleaning is 120r / min, stirring time 3min, centrifuge until the moisture content of the quartz sand is less than 8%;

[0044] (3) Calcination: calcining the c...

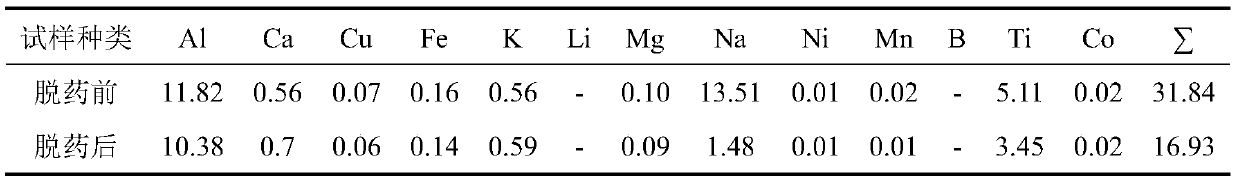

Embodiment 3

[0049] A method for removing drugs by quartz sand flotation, comprising the following steps:

[0050] (1) Dosing and scrubbing: Take the quartz sand after flotation, the particle size of the quartz sand is 0.2-0.3mm, add the mixed agent, the mass ratio of the quartz sand to the mixed agent is 1:2, and the mixed agent includes ammonia water and absolute ethanol , the mass ratio of ammonia water to absolute ethanol is 1:5, scrubbing, the scrubbing speed is 1500r / min, the scrubbing time is 10min, centrifuged until the moisture content of the quartz sand is less than 8%;

[0051] (2) Cleaning with hot pure water: add hot pure water to the centrifuged quartz sand in step (1) to stir and clean, the temperature of pure water is 85°C, the conductivity of pure water is less than 2 μs / cm, and the rotating speed during stirring and cleaning is 150r / min, stirring time 1min, centrifuge until the moisture content of the quartz sand is less than 8%;

[0052] (3) Calcination: calcining the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap