Two-stage reagent removal method for ilmenite flotation concentrate

A technology for flotation concentrates and ilmenite, which is applied in flotation, solid separation, etc., can solve the problems of production process and surrounding environment deterioration, and achieve the effects of good drug removal effect, complete drug removal, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

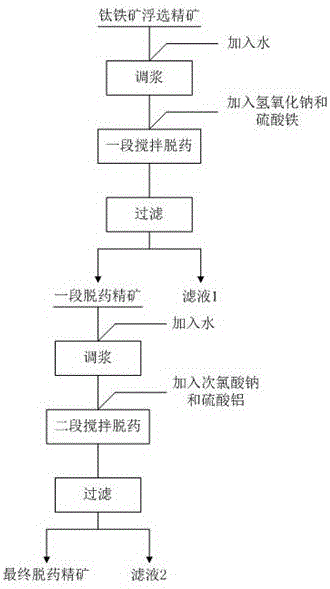

[0023] Such as figure 1 Shown, the two-stage drug-removing method of this ilmenite flotation concentrate, its concrete steps are as follows:

[0024] (1) The first stage of drug removal: the ilmenite flotation concentrate (the concentrate contains TiO 2 45.0wt%, TFe32.6wt%, the main minerals are ilmenite (88.4wt%), titanium magnetite (2.5wt%), (magnetic) pyrite (content 2.6wt%), the rest of the gangue minerals are titanium Pyroxene, plagioclase and amphibole are the main ones. The amount of collector sodium oleate used in flotation is 3000g / t, and the amount of diesel oil is 500g / t). After adjusting the pulp concentration to 25% (m / v), Add 1500g / t sodium hydroxide to adjust the pH to 11-12, then add 2000g / t ferric sulfate and stir thoroughly for 15 minutes, then filter to obtain a stage of drug-free ilmenite flotation concentrate;

[0025] (2) The second stage of drug removal: After adjusting the pulp concentration to 20% of the first stage of drug-free ilmenite flotation co...

Embodiment 2

[0028] Such as figure 1 Shown, the two-stage drug-removing method of this ilmenite flotation concentrate, its concrete steps are as follows:

[0029] (1) The first stage of drug removal: the ilmenite flotation concentrate (the concentrate contains TiO 2 46.5wt%, TFe33.5wt%, the main minerals are ilmenite (89.2wt%), titanium magnetite (2.8wt%), (magnetic) pyrite (content 1.9wt%), the rest of the gangue minerals are titanium Pyroxene, plagioclase and hornblende are the main ones. The amount of collector sodium oleate used in flotation is 3500g / t, and the amount of diesel oil is 800g / t). After adjusting the pulp concentration to 30% (m / v), Add 1800g / t of sodium hydroxide to adjust the pH to 11-12, then add 2200g / t of ferric sulfate and stir thoroughly for 18 minutes, then filter to obtain a stage of drug-free ilmenite flotation concentrate;

[0030] (2) The second stage of drug removal: After adjusting the pulp concentration to 25% of the first stage of drug-free ilmenite flota...

Embodiment 3

[0033] Such as figure 1 Shown, the two-stage drug-removing method of this ilmenite flotation concentrate, its concrete steps are as follows:

[0034] (1) The first stage of drug removal: the ilmenite flotation concentrate (the concentrate contains TiO 2 47.8wt%, TFe32.9wt%, the main minerals are ilmenite (90.4wt%), titanium magnetite (2.2wt%), (magnetic) pyrite (content 2.1wt%), the rest of the gangue minerals are titanium Pyroxene, plagioclase and hornblende are the main ones, the amount of collector sodium oleate used in flotation is 4000g / t, and the amount of diesel oil is 1000g / t) After adjusting the pulp concentration to 35% (m / v), Add 2000g / t of sodium hydroxide to adjust the pH to 11-12, then add 2500g / t of ferric sulfate and stir for 20 minutes, then filter to obtain a stage of drug-free ilmenite flotation concentrate;

[0035] (2) The second stage of drug removal: After adjusting the pulp concentration to 22% of the first stage of drug-free ilmenite flotation concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com