Stacked cutting machine

A cutting machine, stacking technology, applied in metal processing machinery parts, large fixed members, metal processing equipment, etc., can solve the problems of difficult storage, large space ratio, unsuitable height adjustment of the workbench, etc., to achieve easy storage, space The effect of small proportion and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

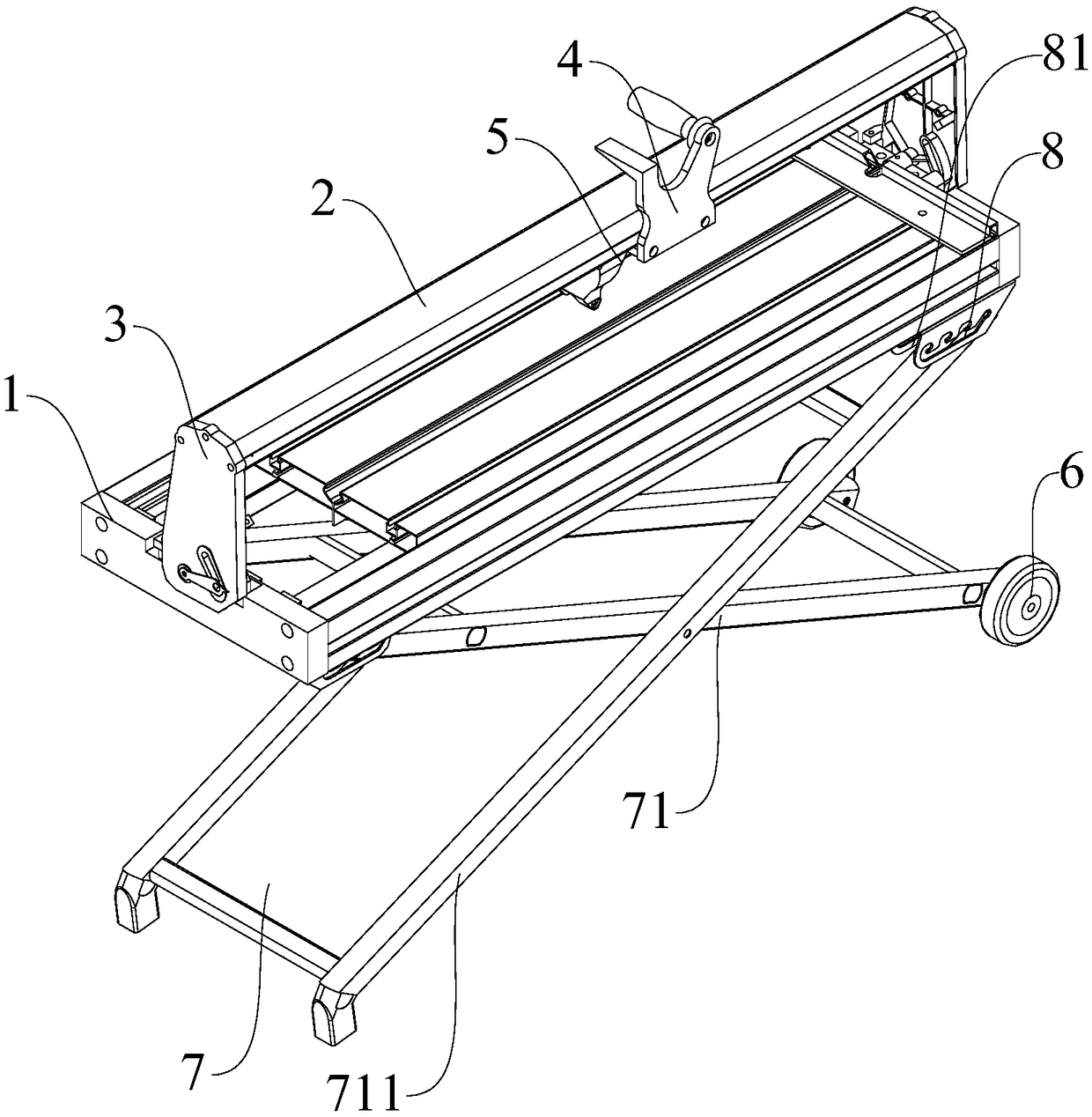

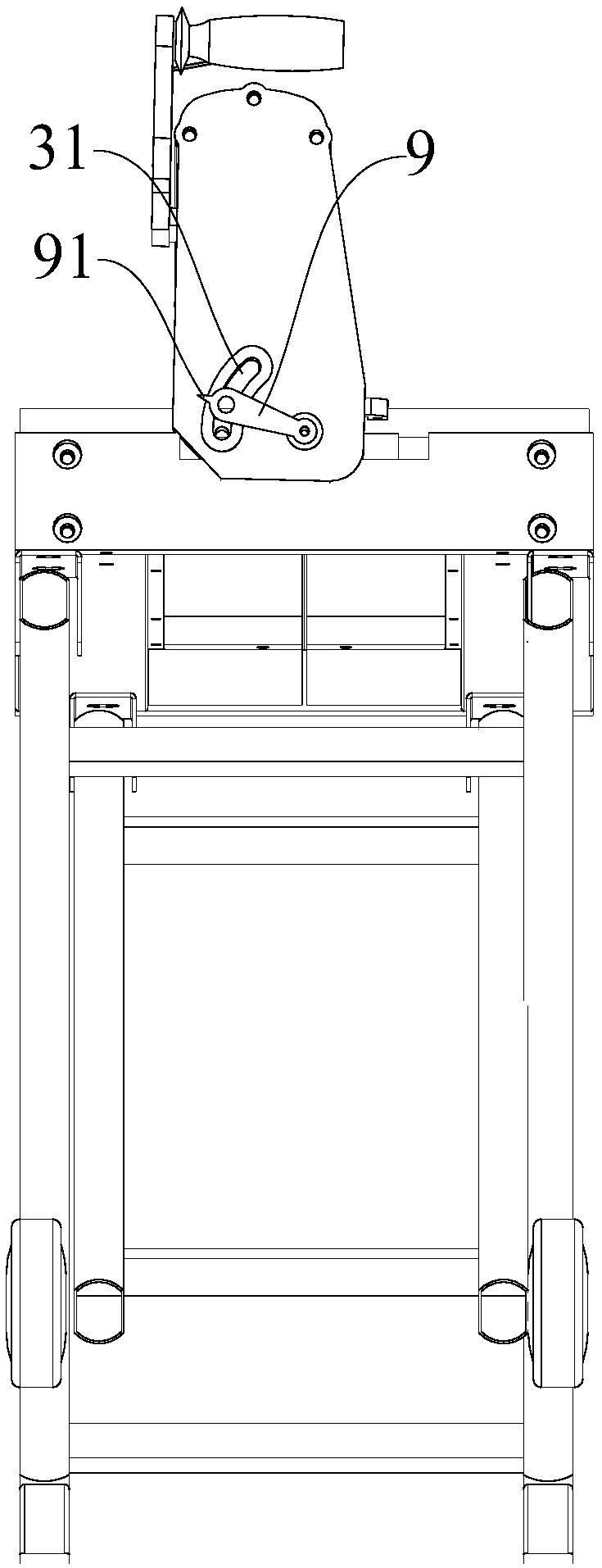

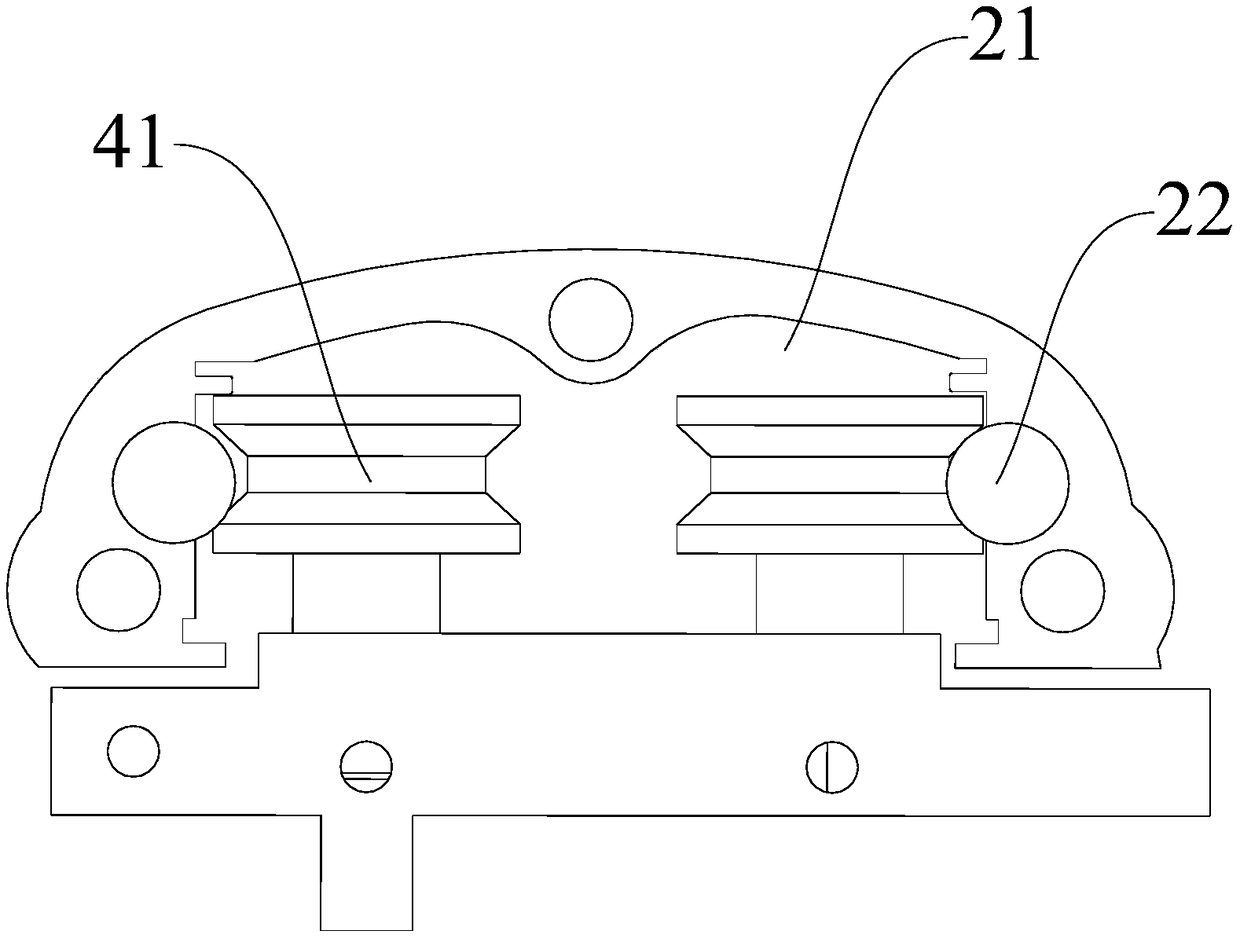

[0019] Such as figure 1 As shown, the top of the workbench 1 is provided with a slide rail 2 parallel to the workbench 1, both ends of the slide rail 2 are connected to the workbench 1 through the support plate 3, and the slide rail 2 is provided with a sliding piece that slides along its length 4. The sliding part 4 is connected to the cutting mechanism 6 through the fixing part 5. The bottom of the workbench 1 is provided with a folding bracket group 7. The folding bracket group 7 includes folding brackets 71 arranged parallel to each other. The folding brackets 71 include supports crossed and pivotally connected to each other. Rods 711, the top of each support rod 711 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com