Rust removal mechanism for components of integrally formed knitting machine

A knitting machine and parts technology, applied in the field of knitting machine parts maintenance device, can solve the problems of fixed rust removal mechanism, inconvenient hand-held conversion, slow rust removal speed by manual operation, etc., and achieves convenient maintenance, convenient multi-purpose use, and increased functions sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

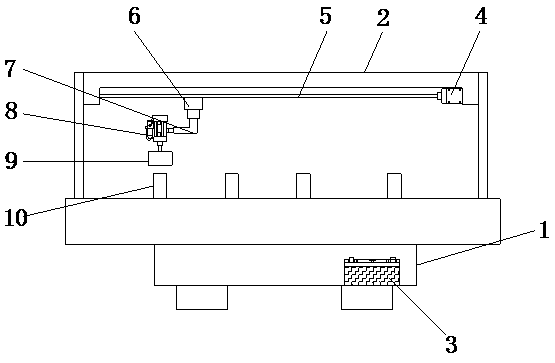

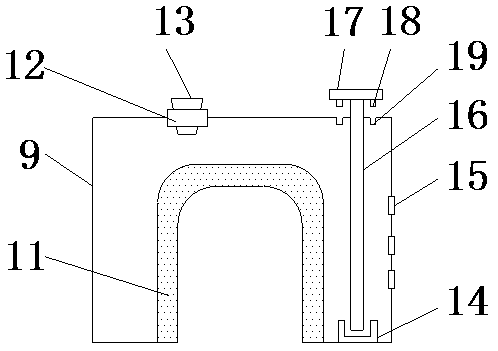

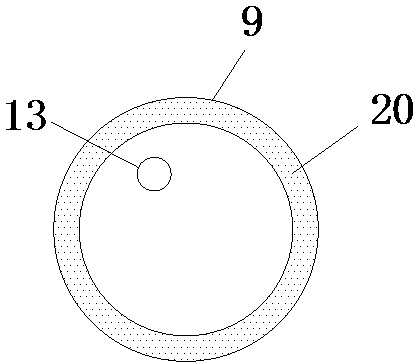

[0021] Figure 1-4 Shown is an integrated rust removal mechanism for knitting machine parts, including a knitting machine base 1, a servo motor 4 is fixed on the right side surface of the mounting bracket 2 above the knitting machine base 1, and a ball screw 5 fixed on the top of the servo motor 4 The lower surface is equipped with an electric telescopic rod 6, and the left side of the fixed L-shaped metal rod 7 on the lower surface of the electric telescopic rod 6 is equipped with a rotating motor 8, and a rust cleaning cylinder 9 is installed on the rotating motor 8 lower side, and the rust cleaning cylinder 9 is connected with the The knitting thread installation sleeves 10 are clamped with each other, and the right side of the rust cleaning cylinder 9 is provided with an oil outlet 15, the upper surface of the knitting machine base 1 is provided with a knitting thread installation sleeve 10, and the rust cleaning cylinder 9 inner surface The first frosting 11 is provided, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com