Automatic container positioning and anti-lifting method for automated loading and unloading operation

An automatic and box-fitting technology, which is applied in the directions of safety devices, transportation and packaging, and load-hanging components, can solve the problems of container anti-lifting detection, safety hazards, and different positions of lock holes at different heights, so as to reduce labor intensity , improve production efficiency, and prevent the truck from lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

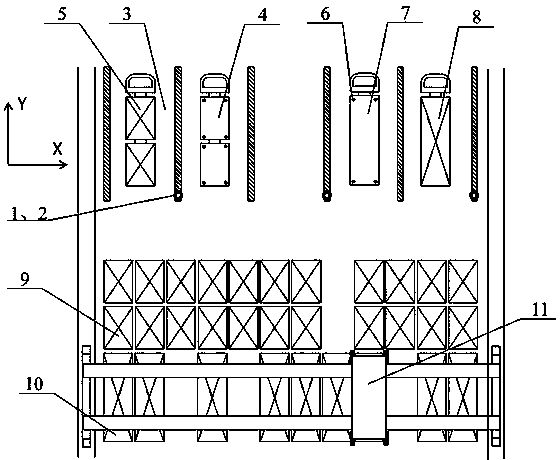

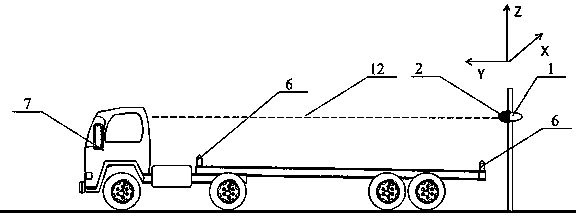

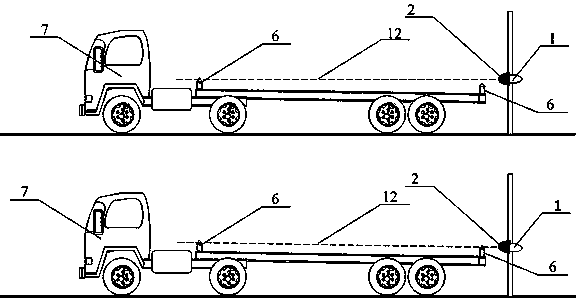

[0031] The automatic lifting device and automatic tilt adjustment device (1) are installed next to the outer collection truck parking lane (3) of the automated dock yard; the laser scanner (2) is installed on the automatic lifting device and automatic tilt adjustment device On (1), the motor driver (17) and the motor (16) control the automatic lifting device and the automatic tilting adjustment device (1) to adjust the lifting and tilting angle of the laser scanner (2), and align it with the lock head of the container truck (6) Tracking detection, through the data measured by the laser scanner (2) and software program processing data to find the sudden change state of the lock head (6) and the container flatbed, determine the reference three-dimensional coordinate position of the lock head (6), and send it to the PLC (15) , to control the position of the spreader (13) and the lock head (6) of the container flatbed truck to realize precise positioning and realize automatic packi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com