Method for preparing spherical baricitinib crystal

A crystallization and spherical technology, applied in the direction of organic chemistry, organic chemistry, etc., can solve the problem of high viscosity of baricotine and achieve good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1. Step 1 Add 10 g of Baricit into 100 ml of water, heat to 40°C to dissolve, prepare a solution with a concentration of 0.10 g / ml, cool to room temperature, and filter.

[0025] Step 2 Keep the temperature of the filtrate in the first step at 5°C, add 20ml of 95% ethanol under stirring, grow crystals at constant temperature for 1 hour, and stir at a stirring speed of 190 rpm.

[0026] The third step The solution obtained in the second step is cooled to -5°C and stirred while continuing to stir, and the constant temperature crystal growth is continued for 1.5 hours. Wherein, the cooling rate is 0.5° C. / minute, and the stirring speed is 190 revolutions / minute.

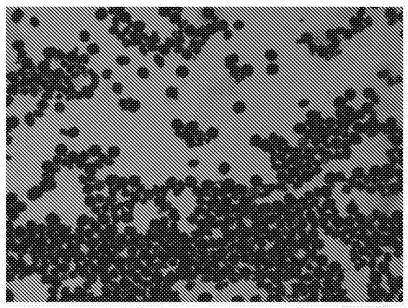

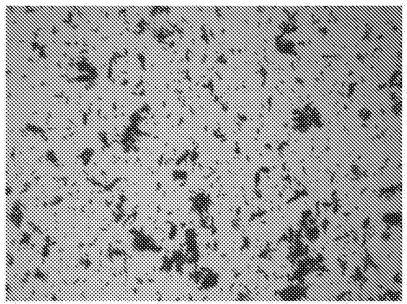

[0027] Step 4 Suction filtration, wash the filter cake with 95% ethanol solution, and dry the filter cake at 50°C. Debarix is a spherical crystal, and its polarized light microscope photo is shown in the appendix figure 1 , D90 is 102μm, the purity detected by HPLC is 99.97%, and the yield is 93.24%. ...

Embodiment 2

[0029] Step 1 Add 25g of Baricit into 100ml of water, heat to 50°C to dissolve, prepare a solution with a concentration of 0.25g / ml, cool to room temperature, and filter;

[0030] Step 2 Keep the temperature of the filtrate in the first step at 15°C, add 30ml of 95% ethanol under stirring, grow the crystal at constant temperature for 2.5 hours, and stir at a stirring speed of 160 rpm;

[0031] The third step, the solution obtained in the second step, continued to stir, cooled to 0°C and stirred, and continued to grow crystals at a constant temperature for 2 hours, wherein the cooling rate was 1°C / min, and the stirring speed was 160 rpm;

[0032] Step 4 Suction filtration, wash the filter cake with 95% ethanol solution, and dry the filter cake at 60°C. Debarix is a spherical crystal, and its polarized light microscope photo is shown in the appendix figure 1 , D90 is 74μm, the purity detected by HPLC is 99.99%, and the yield is 92.02%.

Embodiment 3

[0033] Example 3. In the first step, add 15g of Baricit into 100ml of water, heat to 45°C to dissolve, prepare a solution with a concentration of 0.15g / ml, cool to room temperature, and filter;

[0034] Step 2 Keep the temperature of the filtrate in the first step at 10°C, add 25ml of 95% ethanol under stirring, grow the crystal at constant temperature for 1.8 hours, and stir at a stirring speed of 178 rpm;

[0035] The third step The solution obtained in the second step, continue to stir, cool down to -2.5°C and stir, continue to grow crystals at a constant temperature for 1.8 hours, wherein, the cooling rate is 0.8°C / min, and the stirring speed is 178 rpm;

[0036] Step 4 Suction filtration, wash the filter cake with 95% ethanol solution, and dry the filter cake at 55°C. Debarix is a spherical crystal, and its polarized light microscope photo is shown in the appendix figure 1 , D90 is 80μm, the purity detected by HPLC is 99.99%, and the yield is 92.98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com