Two-tube heat recovery multi-split system and air conditioning outdoor unit thereof

A technology for outdoor units of air conditioners and multi-connection systems, which is applied in refrigerators, compressors, refrigeration components, etc., can solve the problems of small refrigerant circulation, insufficient heating capacity, and low return air density, and achieves increased refrigerant circulation. The effect of improving heating effect and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

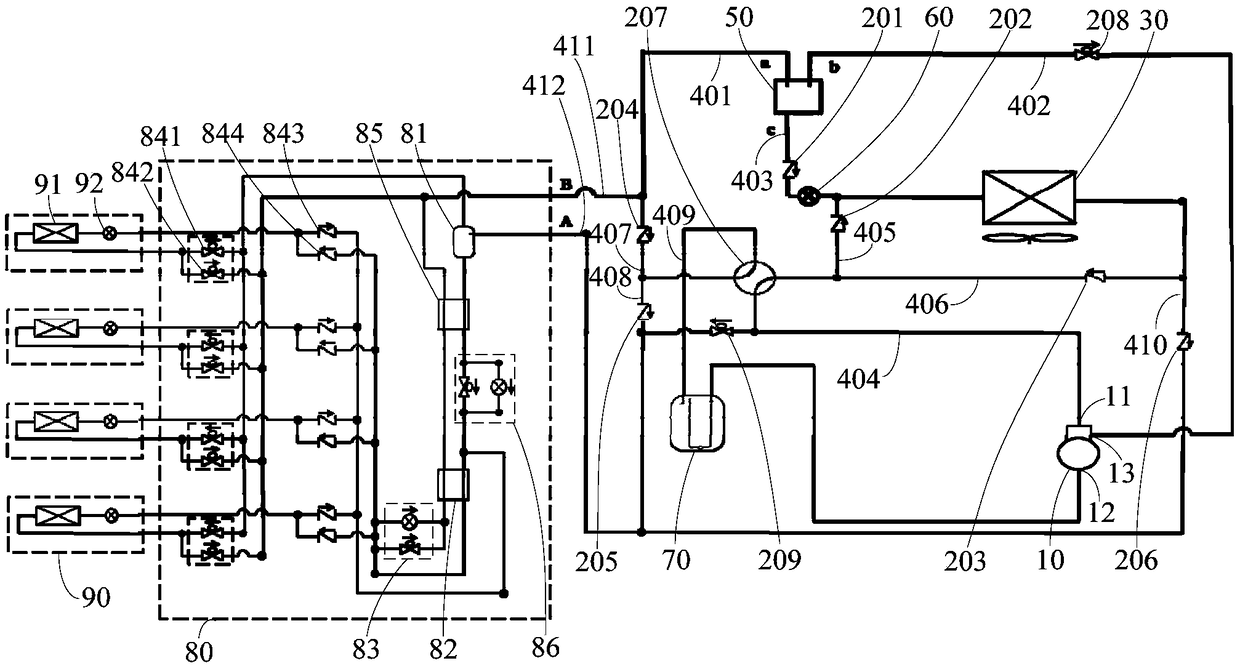

[0075] The second pipeline 402 is provided with a first control valve 208 capable of controlling its on-off, such as figure 1 with figure 2 shown.

[0076] The first control valve 208 is set on the second pipeline 402, and the first control valve 208 can control the on-off of the second pipeline 402, so as to realize the selective on-off of the second pipeline 402. In this way, in cooling operation and other systems When there is no need for enthalpy injection and supplementary air, the second pipeline 402 can be disconnected through the first control valve 208 to prevent other functions of the system (such as pure cooling mode, main cooling mode, etc.) from being affected, thus improving the system efficiency. reliability.

[0077] Preferably, the first control valve 208 is a solenoid valve.

[0078] Using the solenoid valve as the first control valve 208 can not only effectively control the on-off of the second pipeline 402, but also facilitate automatic control in coope...

Embodiment 2

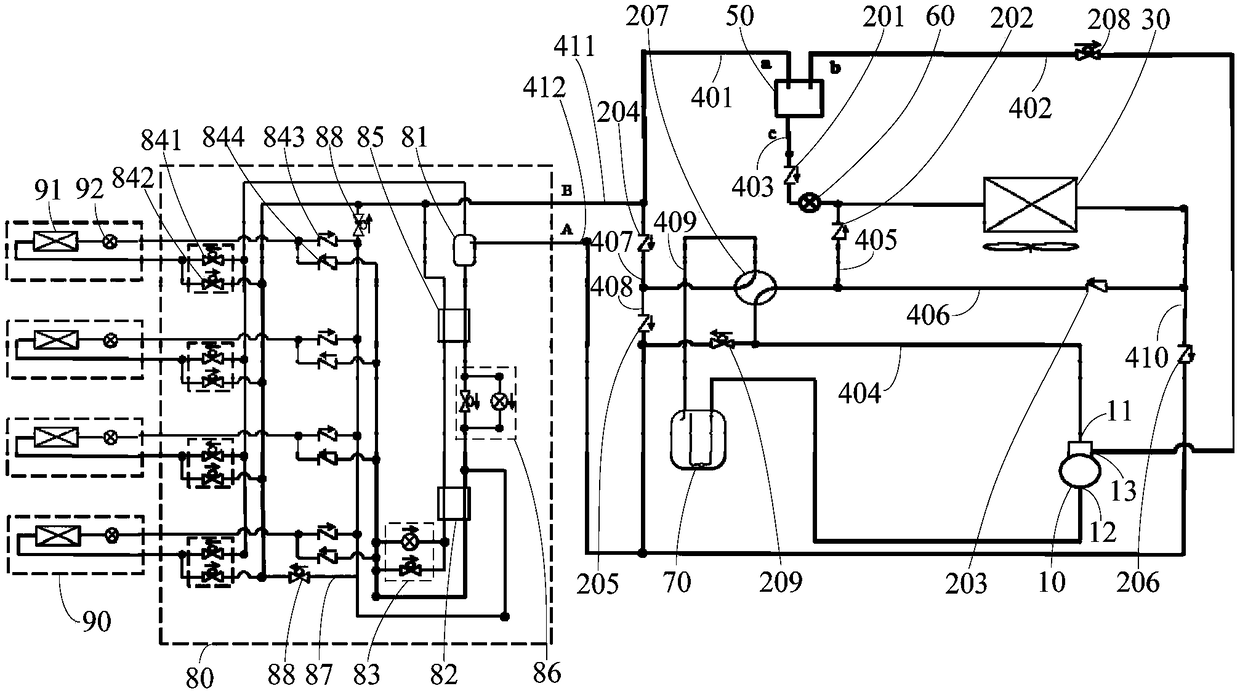

[0099] The difference from Embodiment 1 is that the outdoor throttling device 60 includes multiple throttling elements connected in parallel.

Embodiment 3

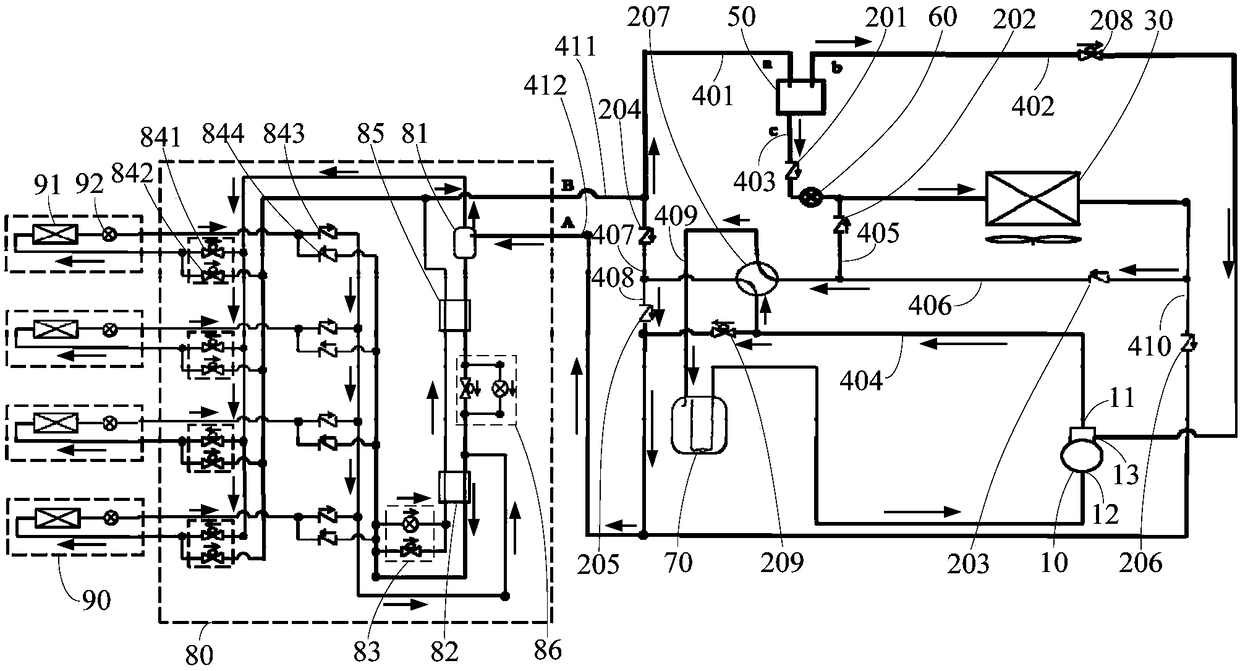

[0101] The difference from Embodiment 1 is that the outdoor throttling device 60 includes at least one throttling element and a flow diversion solenoid valve, and the at least one throttling element and the flow diversion solenoid valve are connected in parallel.

[0102] The outdoor throttling device 60 mainly performs the function of throttling and reducing pressure, and its specific form is not limited. For example: it can include only one throttling element, or it can include multiple throttling elements connected in parallel, or it can be a throttling element and a shunt solenoid valve (that is, a solenoid valve that acts as a shunt to prevent all refrigerant from entering the throttling Components) parallel combination, etc., can also be other forms; and the form of the throttling element is not limited, such as capillary, electronic expansion valve 92, etc., are not listed here, because all can achieve throttling reduction Pressure function, and do not deviate from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com