Lactating sow fermented feed drying device

A technology for fermented feed and lactating sows, which is applied in the directions of drying gas arrangement, drying solid materials, and dry goods processing, etc., and can solve the problems that the drying device for fermented feed for lactating sows cannot be quickly dried and evenly dispersed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

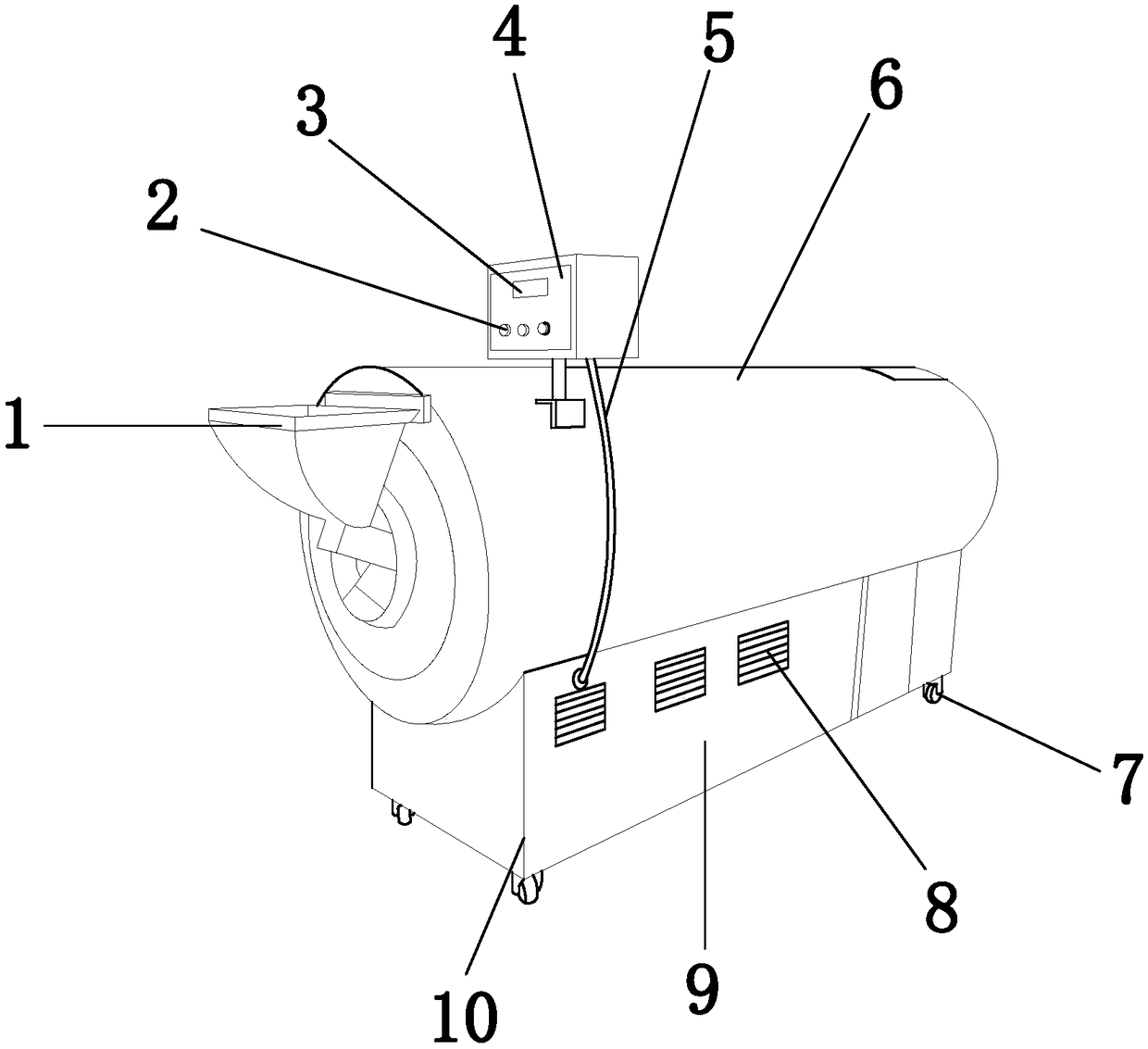

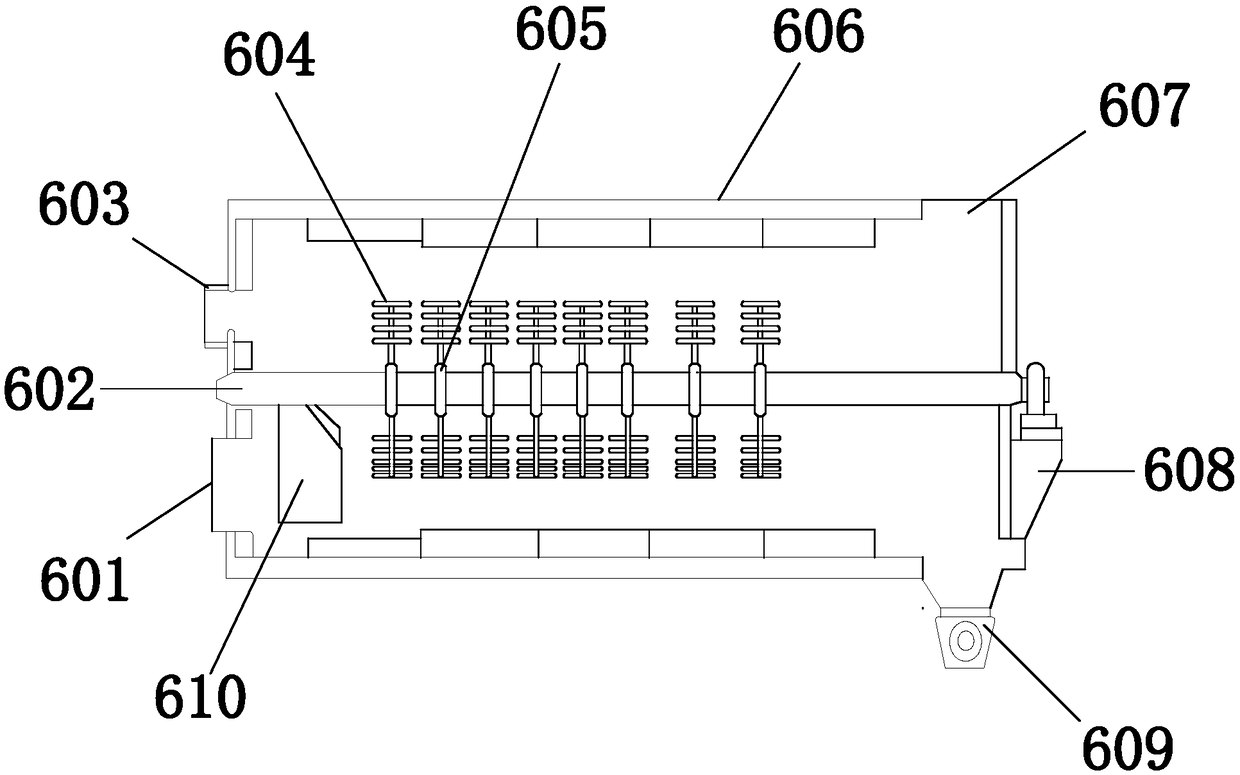

[0020] see Figure 1-2 , the present invention provides a lactating sow fermented feed drying device: its structure includes a feed hopper 1, operation buttons 2, a display screen 3, a controller 4, a wire 5, a dispersing drying device 6, casters 7, and a heat dissipation port 8 , drying machine 9, box body 10; the box body 10 is provided with casters 7 evenly and equidistantly at the bottom of the rectangle, and the caster wheels 7 are fixed on the bottom of the box body 10, and the left and right sides of the box body 10 are evenly spaced, etc. There are six cooling vents 8, and the cooling vents 8 and the box body 10 are an integrated structure, and the inside of the box body 10 is provided with a dryer 9, and the dryer 9 is fixed on the box bo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap