Die-cut product appearance detection machine

A testing machine and testing mechanism technology, applied in measurement devices, optical testing flaws/defects, instruments, etc., can solve problems such as single testing items, high labor costs, and no unified testing standards, achieve high testing efficiency, and save enterprise costs. , The effect of preventing mobile phone quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

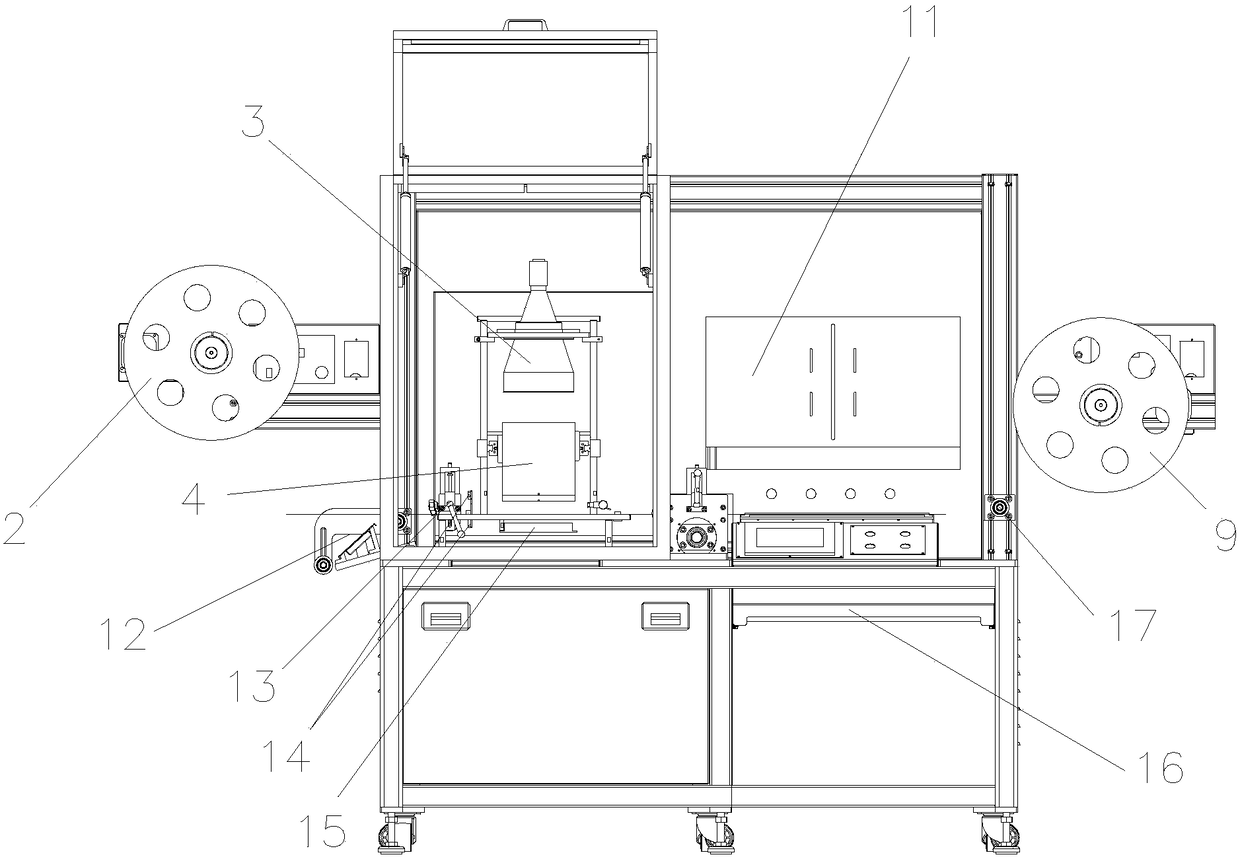

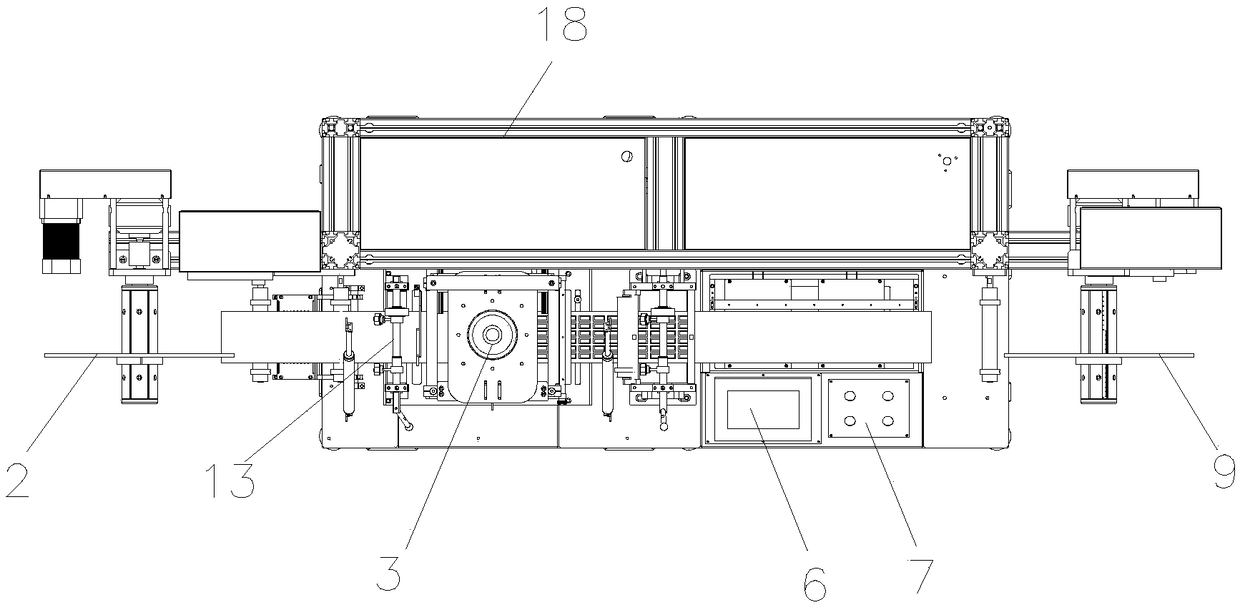

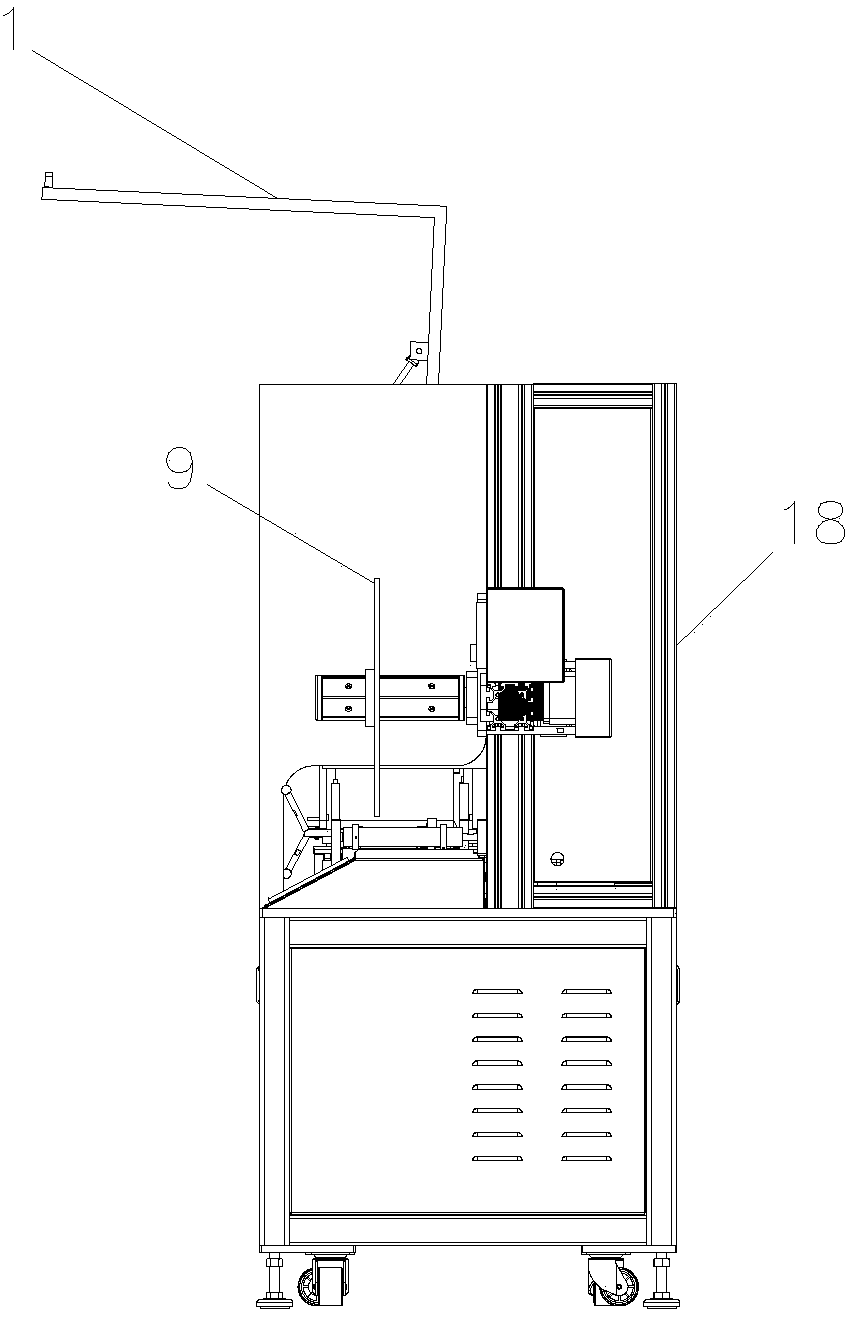

[0030] see Figure 1-6 , a die-cut product appearance inspection machine, comprising a body 18, a feeding shaft 2, a detection mechanism, an operating platform, a feeding shaft 9, a display 11, a suction platform 12, a pressure wheel mechanism 13 and a sensor 14;

[0031] The middle part of the body 18 is provided with a horizontal detection platform, and the body 18 is also provided with a vertical partition plate. The lower end of the partition plate is provided with an opening for the passage of products. On the platform, a protective cover 1 is rotatably connected to the top of the left end of the body 18, and the left and right ends of the protective cover 1 are respectively hinged with the left side wall of the body 18 and the partition plate; the protective cover 1 is used to block external light;

[0032] The left side of the body 18 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com