Method for detecting defects in and on film

A detection method and internal defect technology, which is applied in the field of optical detection, can solve the problems of film defects on the film and the inability to distinguish the defects in the film or on the film, so as to improve the detection rate, reduce network traffic and storage space, and increase production capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

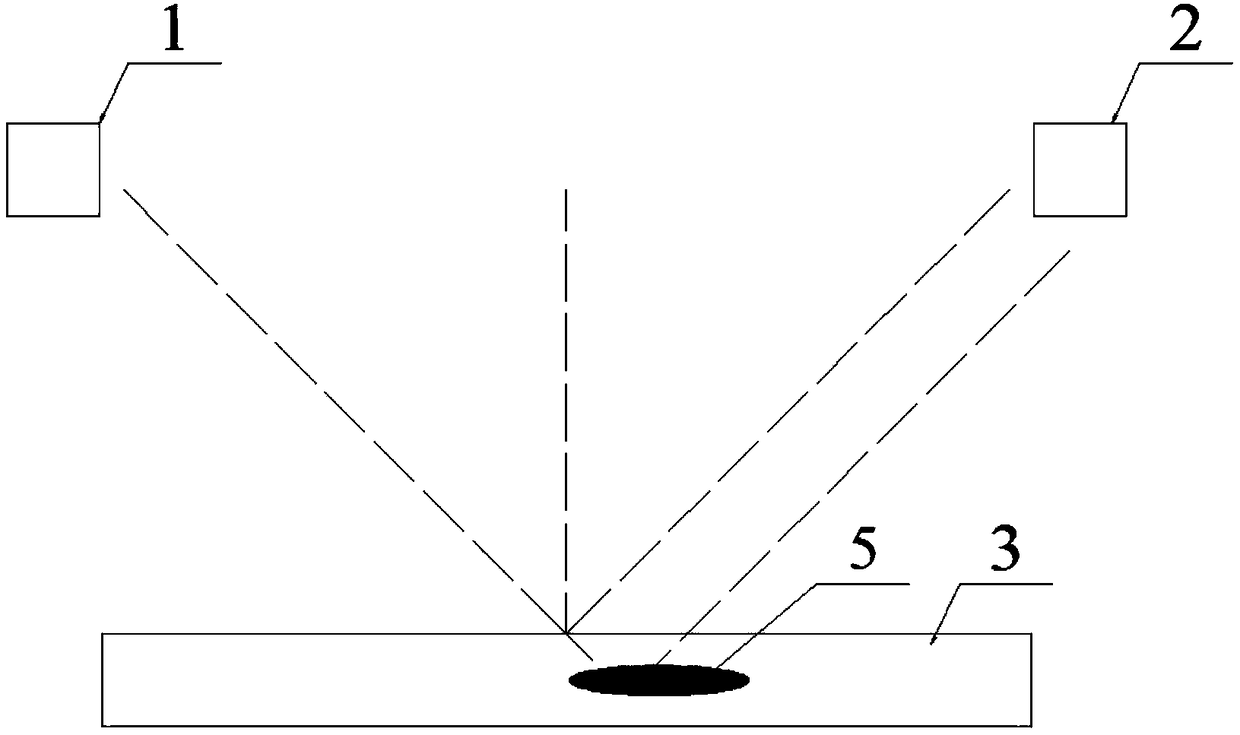

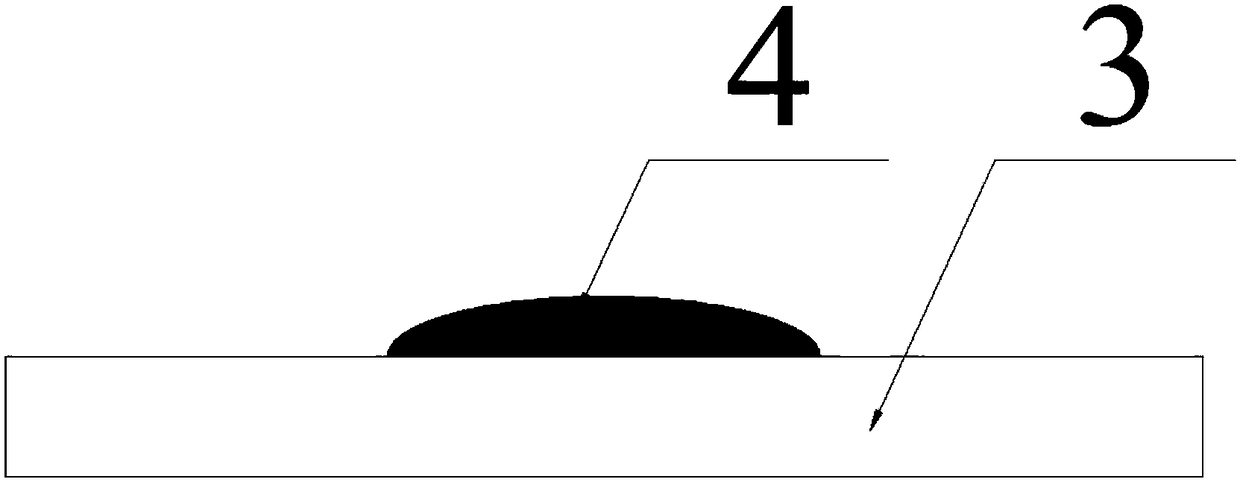

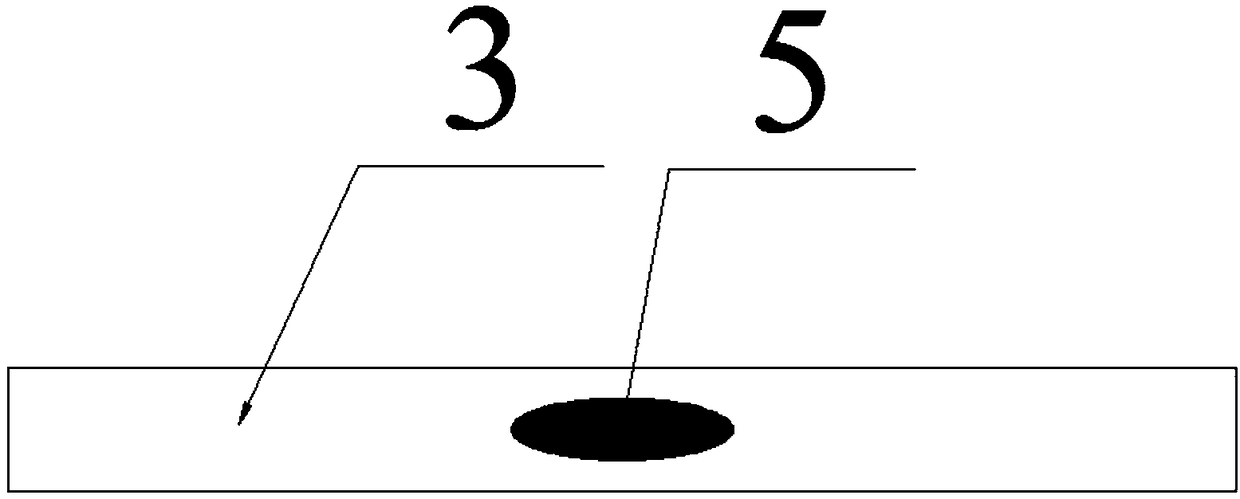

[0029] The schematic diagram of this embodiment is as Figure 1~3 As shown, the image capture unit 1 and the defect scanning unit 2 are used to capture images of the substrate to be tested on which the transparent film 3 is deposited, and then through data analysis of the captured image information, the defect is determined by the analysis results (this embodiment considers transparent There are some defective parts on the film 3, the defective parts are independent individuals, and the adjacent defective parts are distributed at intervals). Are the defects 4 on the transparent film 3 or the internal defects 5 located in the transparent film 3? This embodiment is to be tested The substrate is a flexible substrate or a glass substrate. The image capturing unit 1 of this embodiment is a high-precision optical camera, and the defect scanning unit 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com