Mounter and its bottom mirror vision system

A vision system and placement machine technology, applied in optics, instruments, photography, etc., can solve problems affecting image recognition speed, time-consuming multiple images, time-consuming image processing, etc., to shorten image processing time and avoid unclear images , Reduce the effect of taking pictures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

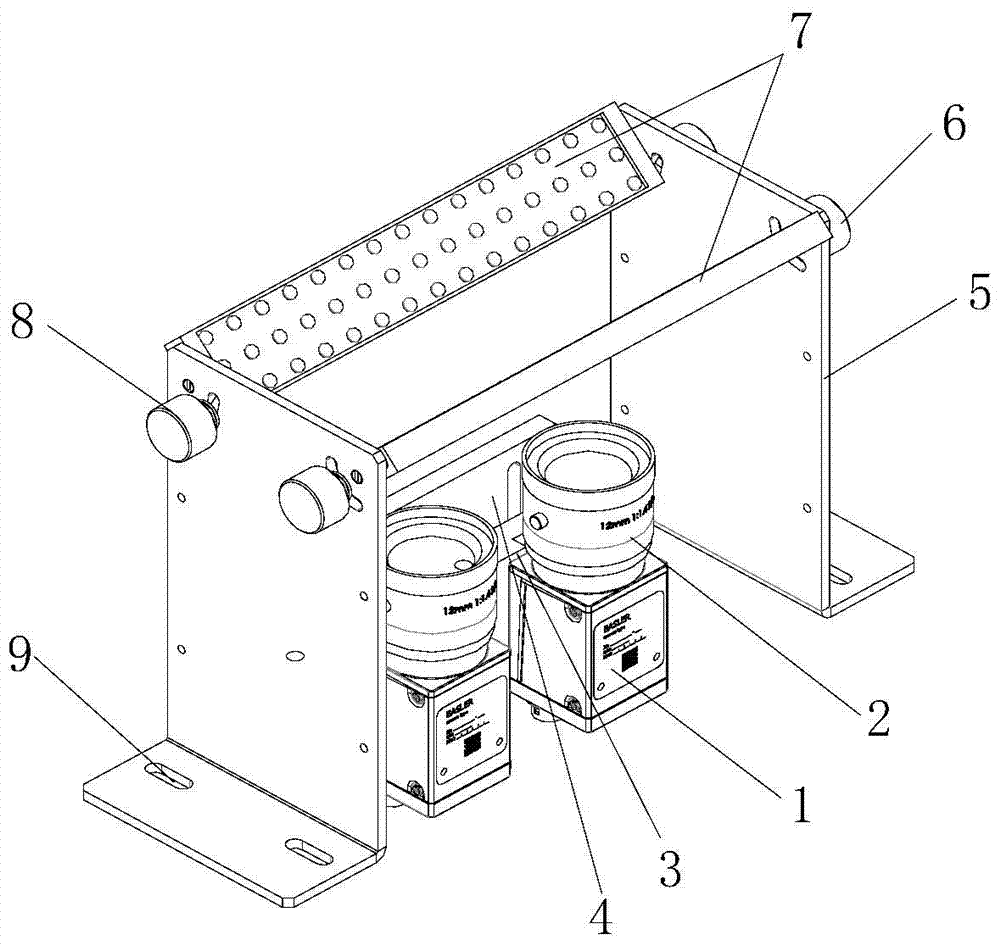

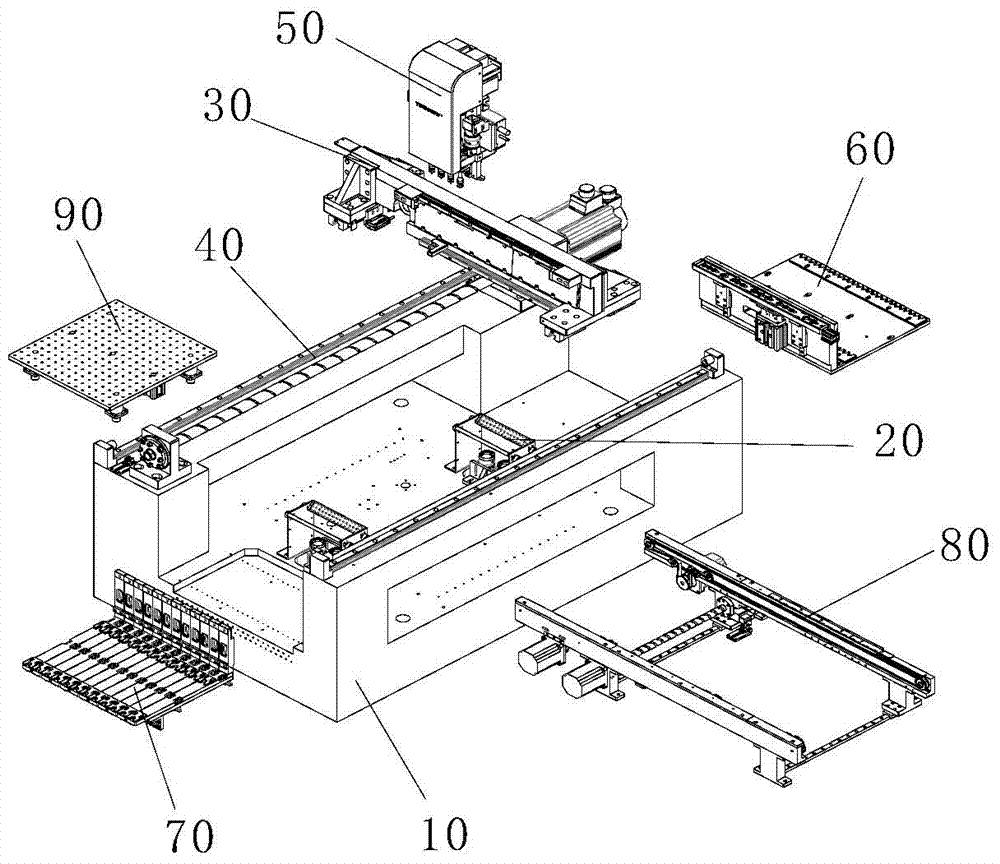

[0026] figure 1 Schematic diagram of the structure of the bottom mirror vision system of the placement machine provided by the embodiment of the present invention; figure 2 It is a schematic diagram of an exploded structure of a placement machine provided by an embodiment of the present invention. refer to figure 1 and figure 2 , Mounter bottom mirror vision system 20, including:

[0027] The camera installation base 4 is arranged on the placement machine platform 10;

[0028] The camera mounting plate 3 is arranged on the camera mounting base 3 in an adjustable position;

[0029] The camera 1 is arranged on the corresponding camera mounting plate 3 in an adjustable position;

[0030] Two light source mounting bases 5 are arranged on the mounter platform 10, and the two light source mounting bases 5 are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com