An automatic carpet cutting device and method using real-time machine vision technology

An automatic cutting device, real-time vision technology, applied in the directions of transportation and packaging, sending objects, thin material processing, etc., can solve the problems of low co-seat efficiency, inability to guarantee cutting accuracy, large carpet edge error, etc., to achieve high cutting accuracy, Save photo time, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

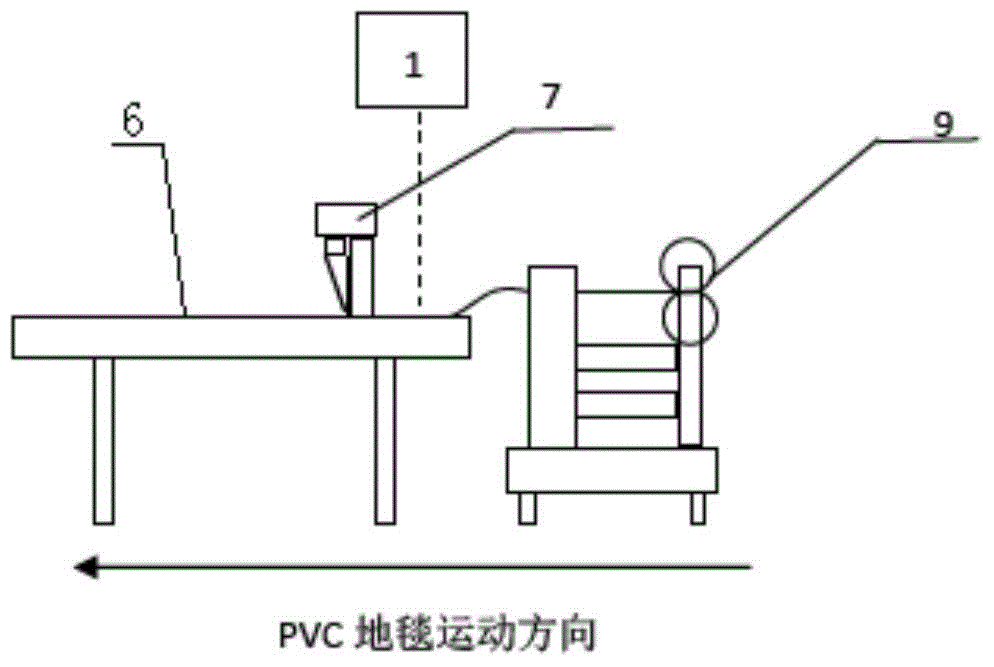

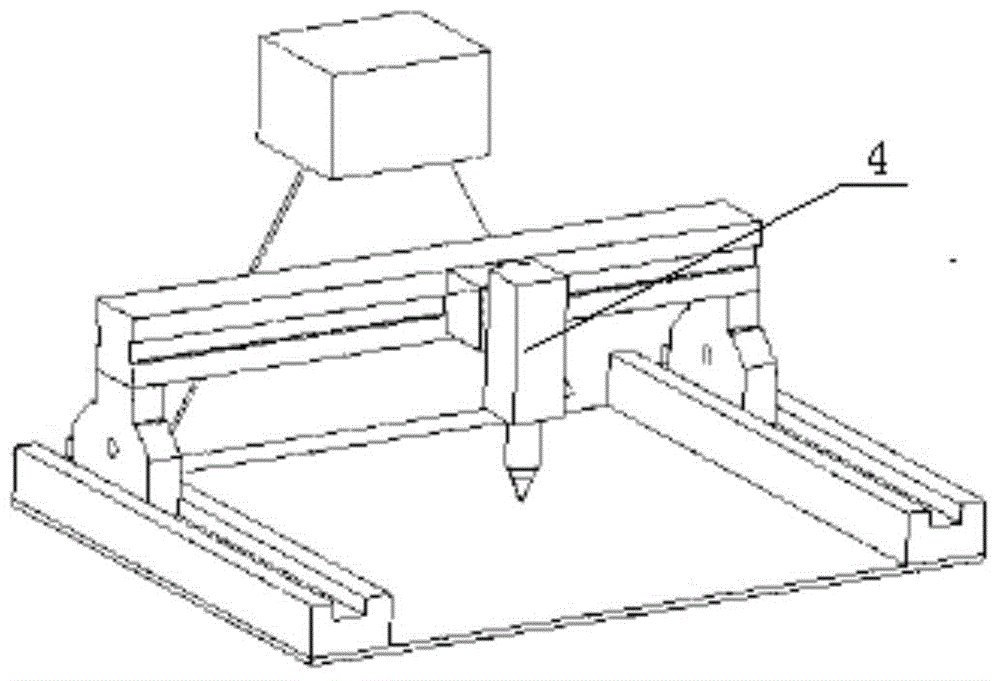

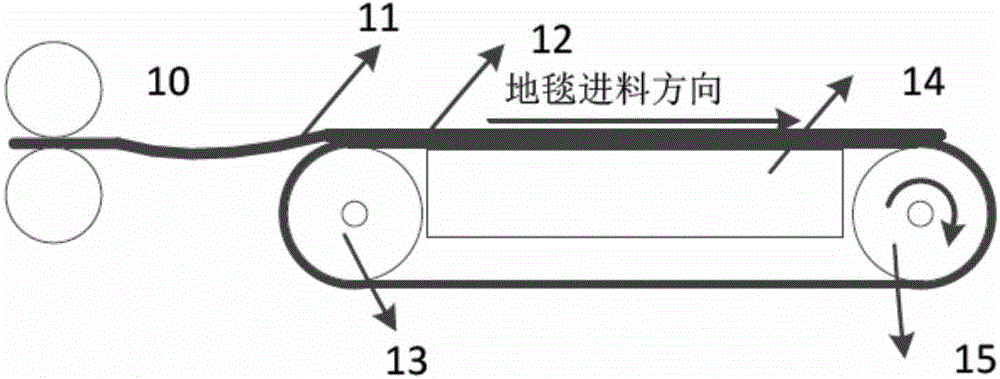

[0048] figure 1 , Picture 10 In this embodiment, it includes a cutting platform 6 which is matched with the discharge port of the pressure roller feeder 9 which includes a motor, a driving wheel and a driven wheel. There is a certain gap between the driving wheel and the driven wheel. During the heat-melting process of PVC carpet production, the PVC base material continuously moves out of the heat-melting mechanism with a fixed width. At this time, the cut carpet body, which can be rectangular sheets of various sizes, has been placed on the PVC substrate to form the PVC carpet 11. When feeding, the PVC carpet 11 is put into the gap, and the driving wheel presses the driven wheel and rotates to drive the PVC carpet 11 forward, so that the PVC carpet 11 moves to the cutting platform 6. When the PVC carpet 11 covers the cutting area of the cutting platform 6, the driving wheel stops rotating.

[0049] A line scan camera 1 is provided above the feed inlet where the cutting platf...

Embodiment 2

[0068] Such as Picture 11 , Figure 11a As shown, in this embodiment, if the width of the cutting platform 6 is too large to cover the entire width direction with one line scan camera 1, multiple line scan cameras 1 can be used to coordinate work, and each line scan camera 1 Covering a part of the width direction of the cutting platform 6, the images of multiple line scan cameras 1 can cover the entire width direction when combined.

[0069] In this embodiment, two line scan cameras 1 are used, and each line scan camera 1 processes a part of the width direction of the cutting platform 6 to take pictures. The field of view of the two line scan cameras 1 may overlap partially.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com