Evaluation method for safe operation of equipment in refinery

A technology for safe operation and equipment, applied in the direction of instruments, manufacturing computing systems, data processing applications, etc., can solve problems such as poor security and achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

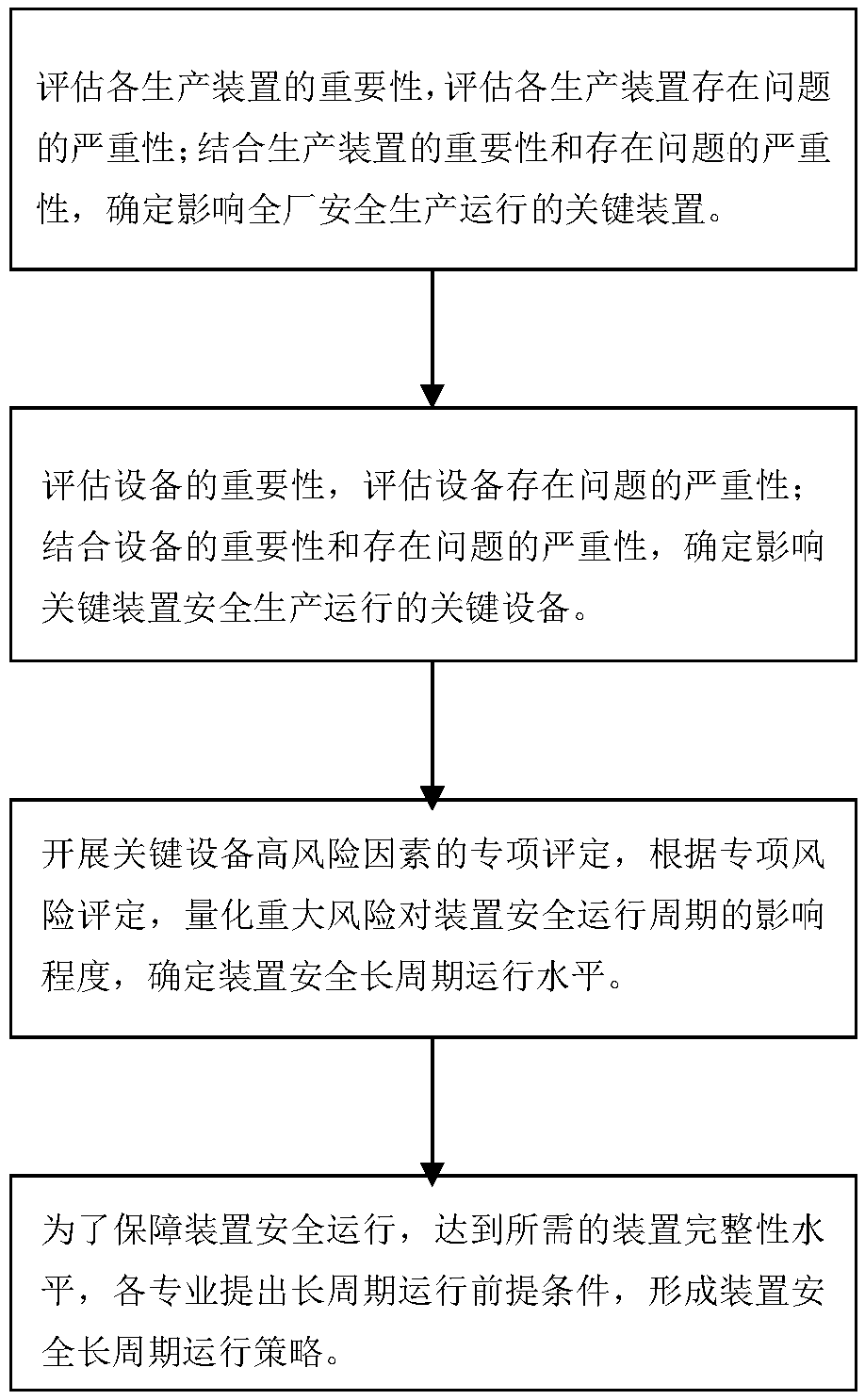

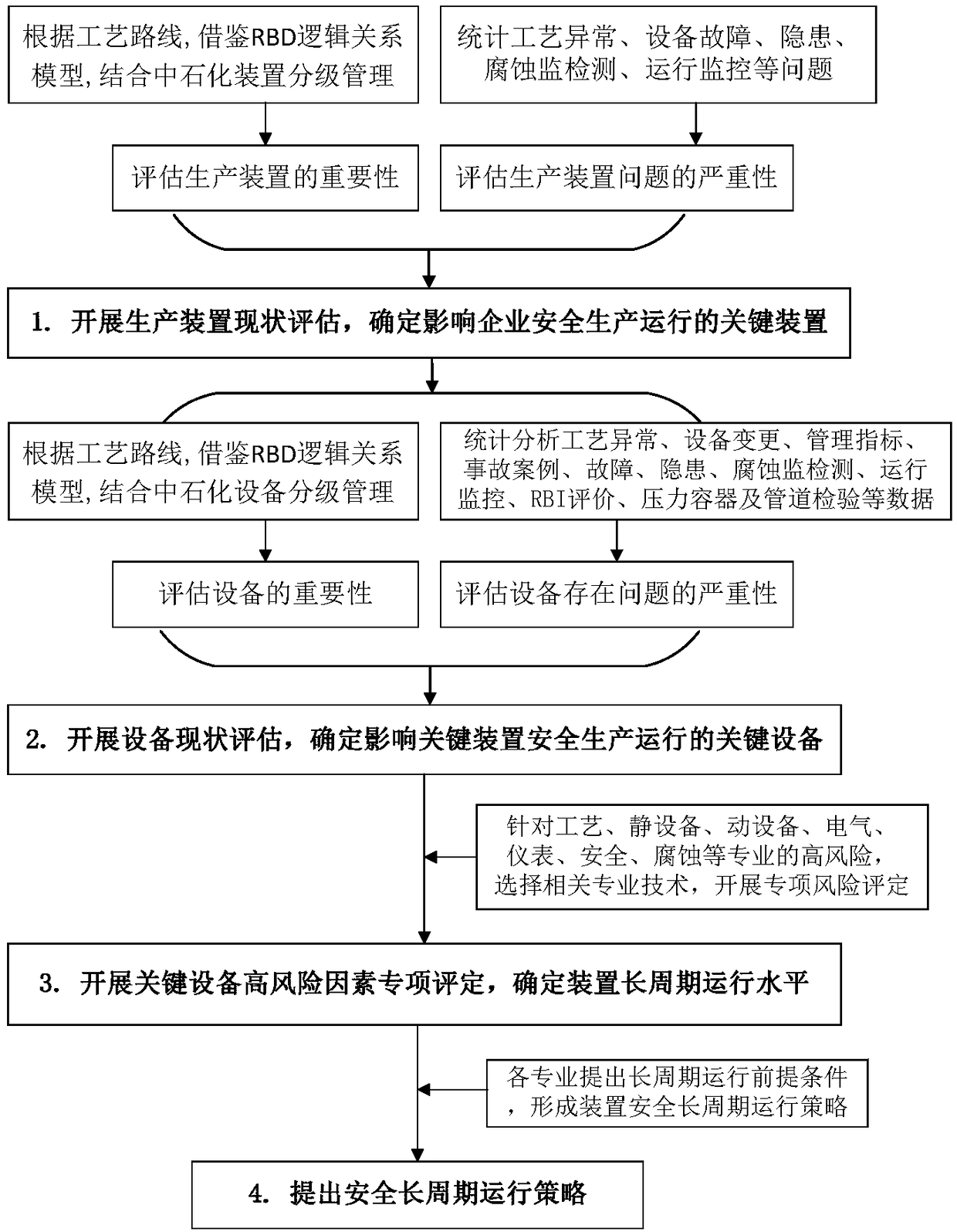

[0035] An evaluation method for the safe operation of refinery equipment, such as figure 1 , figure 2 shown, including the following steps:

[0036] 1. Carry out the current situation assessment of production equipment and determine the key equipment that affects the safe production and operation of the enterprise

[0037] a. According to the overall production process of the whole plant, material balance, heat balance, sulfur balance, hydrogen balance, drawing on the RBD logical relationship model, combined with Sinopec's hierarchical management of equipment, evaluate the importance of each production unit;

[0038] b. Statistically analyze the process abnormalities, equipment failures, hidden dangers, corrosion monitoring, operation monitoring and other data of each production device, and evaluate the severity of the problems in each production device;

[0039] c. Combining the importance of production equipment and the severity of existing problems, apply the risk matrix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com