Reflowable Thermal Cutoffs

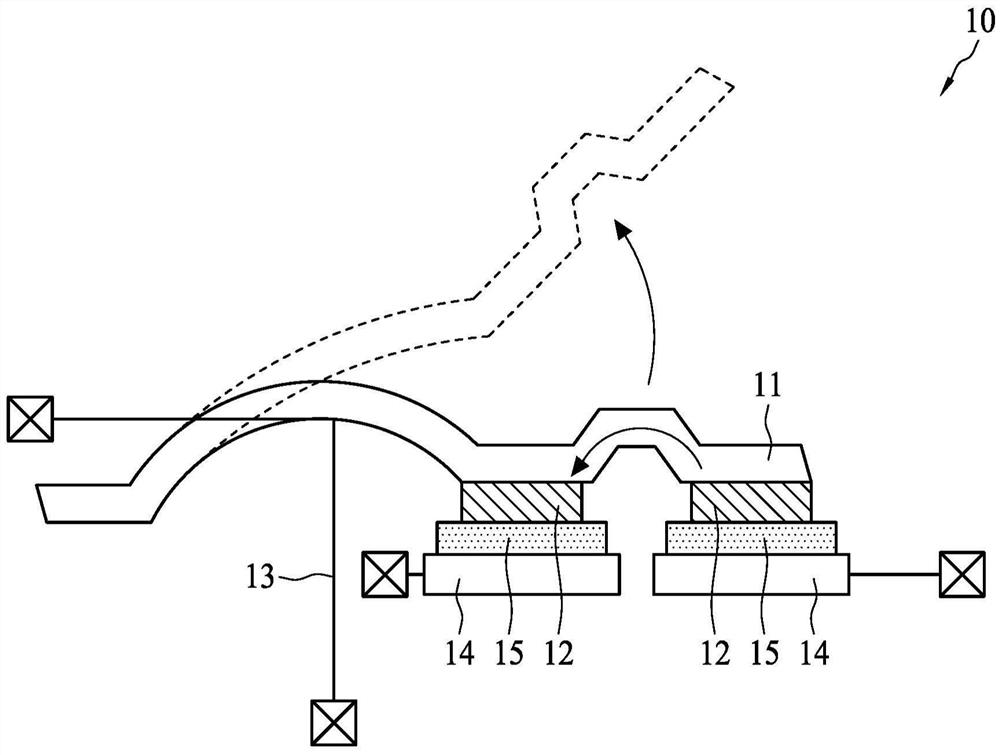

A thermal fuse, welding technology, applied in the direction of protection switch operation/release mechanism, electrical components, thermal switches, etc., can solve the problems of complex structure of reflowable thermal fuse, achieve simplified structure, avoid tension reduction, accurate fixed or maintained effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to make the above and other technical content, features and advantages of the present invention more comprehensible, the following specifically cites relevant embodiments, together with the accompanying drawings, for a detailed description as follows.

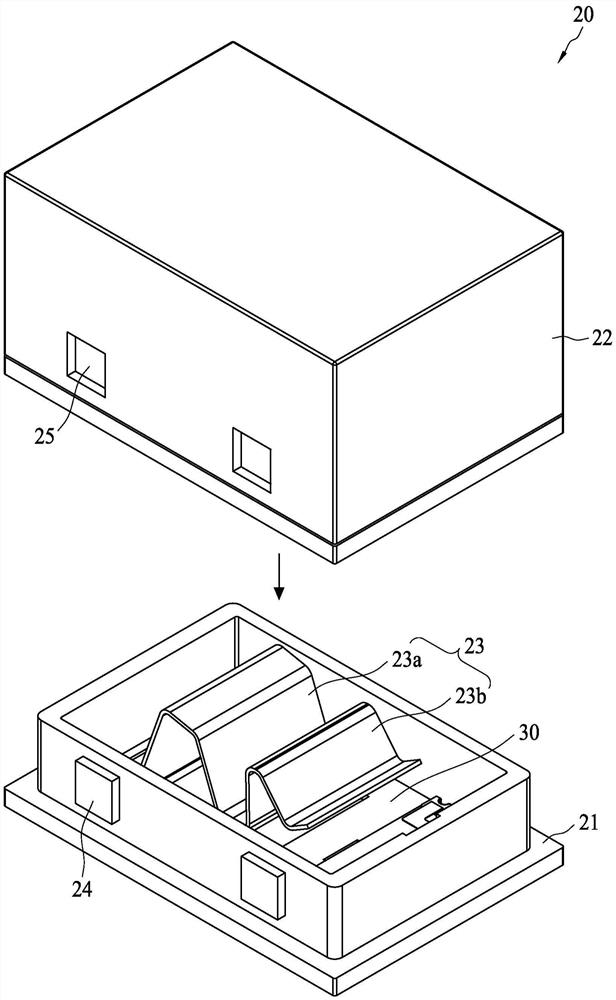

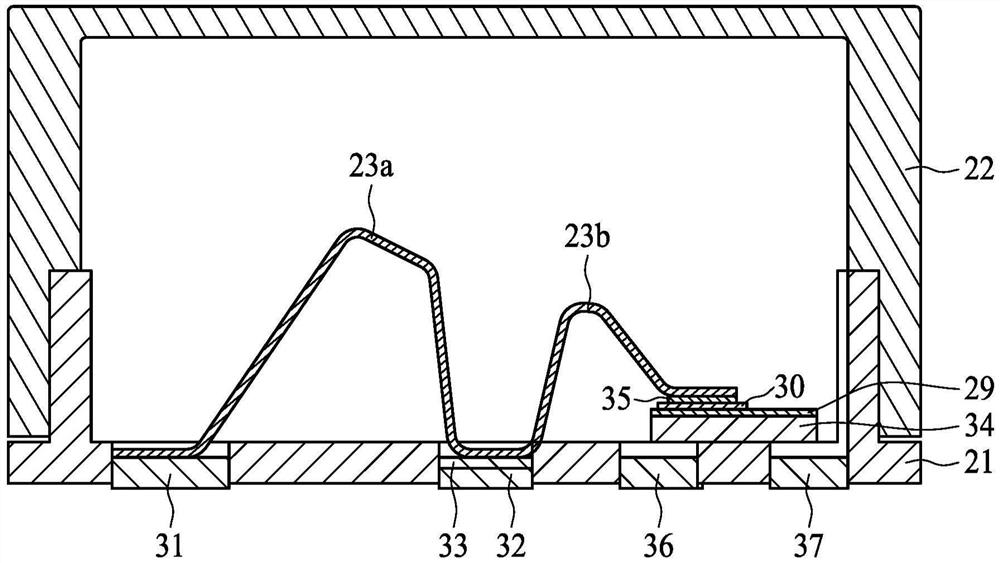

[0064] figure 2 A reflowable thermal fuse 20 according to an embodiment of the present invention is shown in an actuated state. The base 21 cooperates with the cover 22 to form an inner space capable of accommodating necessary components of the reflowable thermal fuse 20 . The conductive member 23 is disposed on the base 21 and includes a first elastic portion 23 a and a second elastic portion 23 b. The side wall of the base 21 is provided with a protruding block 24, and the protruding block 24 can engage with the notch 25 of the side wall of the housing 22, so as to combine the two. The conductive member 23 can be bent from a single metal sheet to form two arched portions, which respectively correspond to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com