Battery box for electric vehicle

A technology for battery boxes and electric vehicles, applied in the field of materials, can solve the problems of easily damaged batteries, decreased specific capacity of battery boxes, and heavy weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

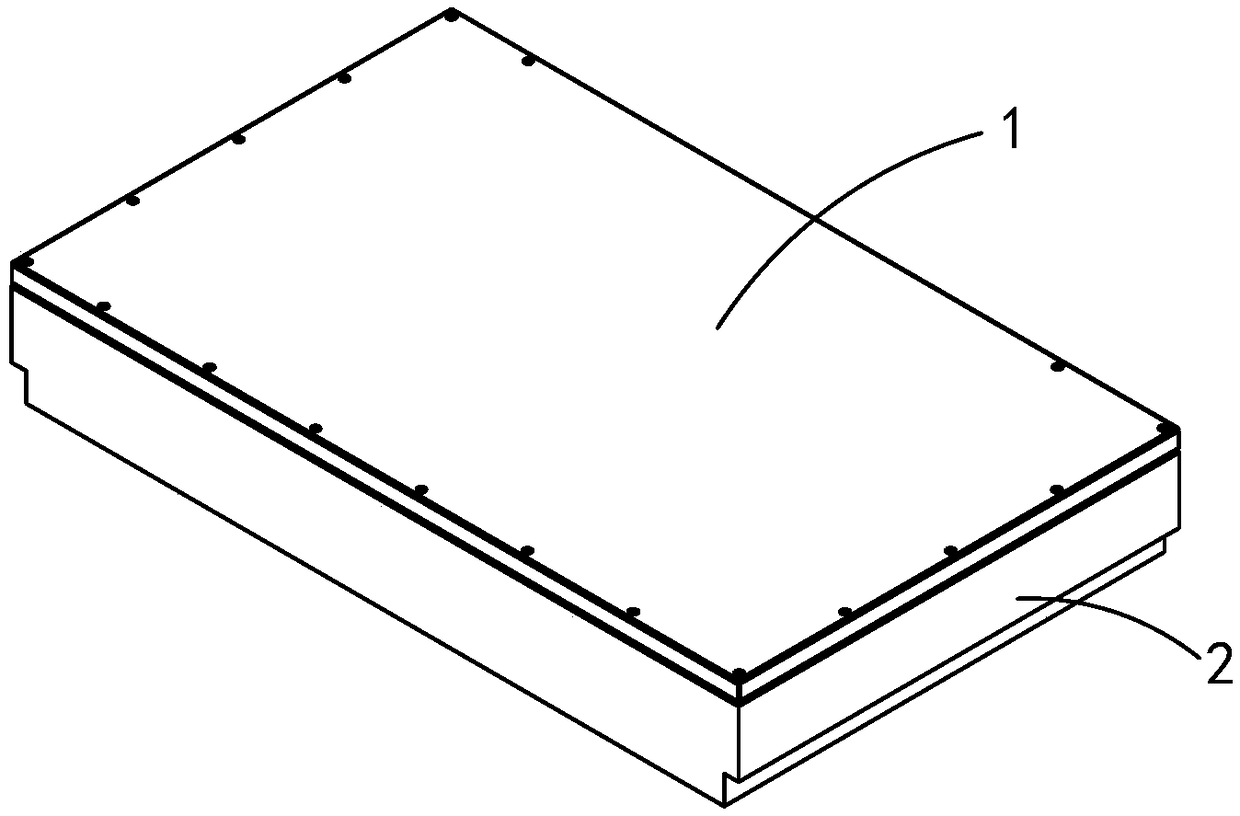

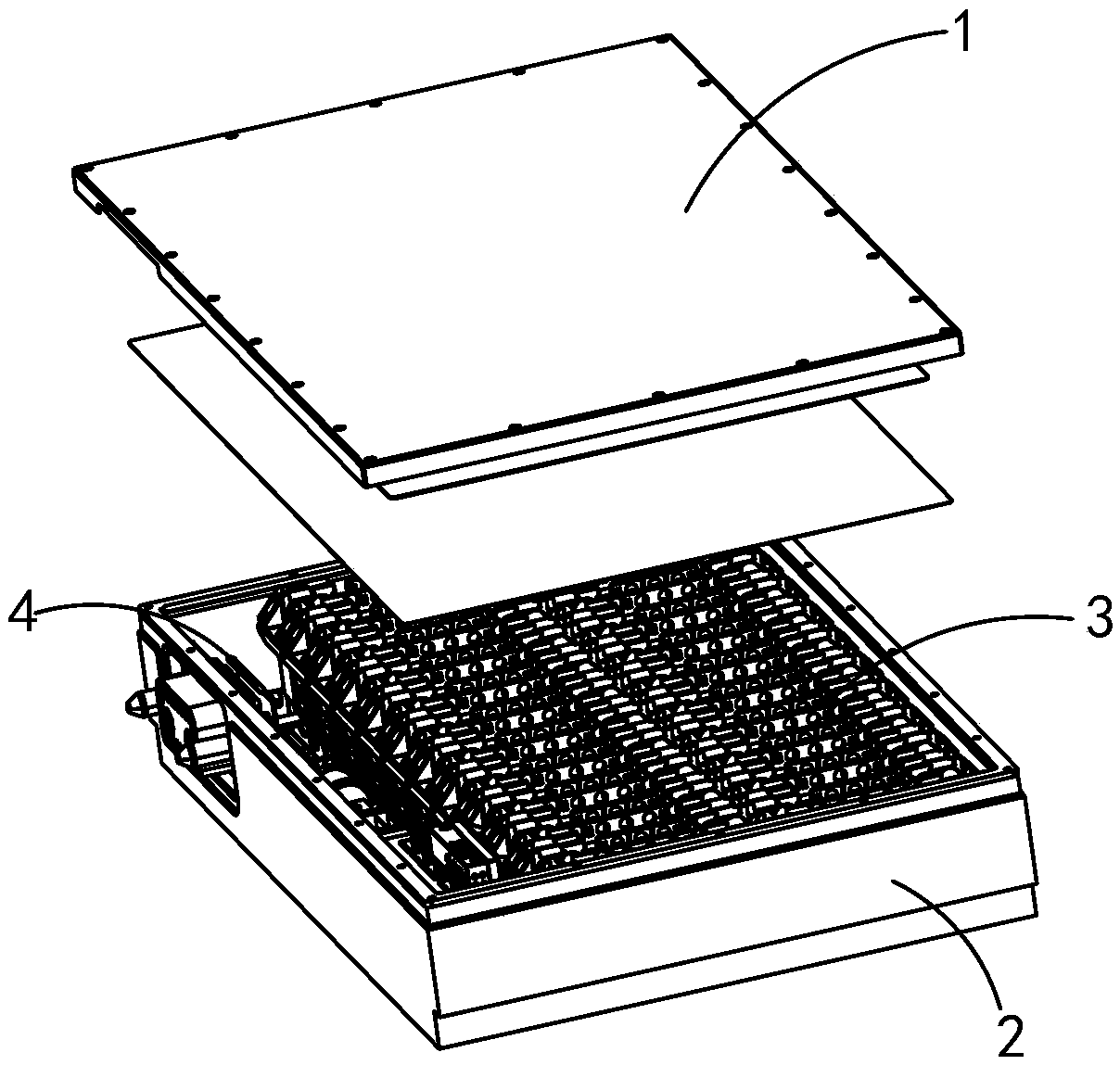

[0016] see Figure 1-2 .

[0017] This embodiment provides an electric vehicle battery box, including a box cover 1 , a box body 2 , a battery pack 3 and an auxiliary assembly 4 .

[0018] The battery pack 3 and the auxiliary components 4 are both arranged in the box body 2, the box cover 1 covers the opening of the box body 2, the battery pack 3 is electrically connected with the auxiliary components 4 to realize the charging and discharging of the battery pack 3, and the box body 2 includes The front side wall and the rear side wall are oppositely arranged, the battery pack 3 is pressed on the front side wall, the auxiliary component 4 is pressed on the rear side wall, there is a gap between the auxiliary component 4 and the box cover 1, and the gap is filled with buffer Insulation Materials.

[0019] The composition of the buffer insulating material is calculated in parts by mass:

[0020] Linear low density polyethylene with a density of 0.92g / cm 3 , 50 copies;

[002...

Embodiment 2

[0029] The composition of the buffer insulating material in this embodiment is calculated in parts by mass:

[0030] Linear low density polyethylene with a density of 0.925g / cm 3 , 50 copies;

[0031] Polyethylene glycol, molecular weight 800-1000, 30 parts;

[0032] Polypropylene, 10 servings;

[0033] Tricresyl Phosphate, 10 parts.

[0034] The average density of the buffer insulating material in this embodiment is 1.17 g / cm 3 .

Embodiment 3

[0036] The composition of the buffer insulating material in this embodiment is calculated in parts by mass:

[0037] Linear low density polyethylene with a density of 0.92g / cm 3 , 60 copies;

[0038] Polyethylene glycol, molecular weight 800-1000, 20 parts;

[0039] Polypropylene, 10 servings;

[0040] Tricresyl Phosphate, 10 parts.

[0041] The average density of the buffer insulating material in this embodiment is 1.08g / cm 3 . In addition, the fluidity of the buffer insulating material is reduced to a certain extent compared with Example 1, and it is not easy to enter the void.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Average density | aaaaa | aaaaa |

| Average density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com