A kind of positive electrode material of spherical sodium ion battery and preparation method thereof

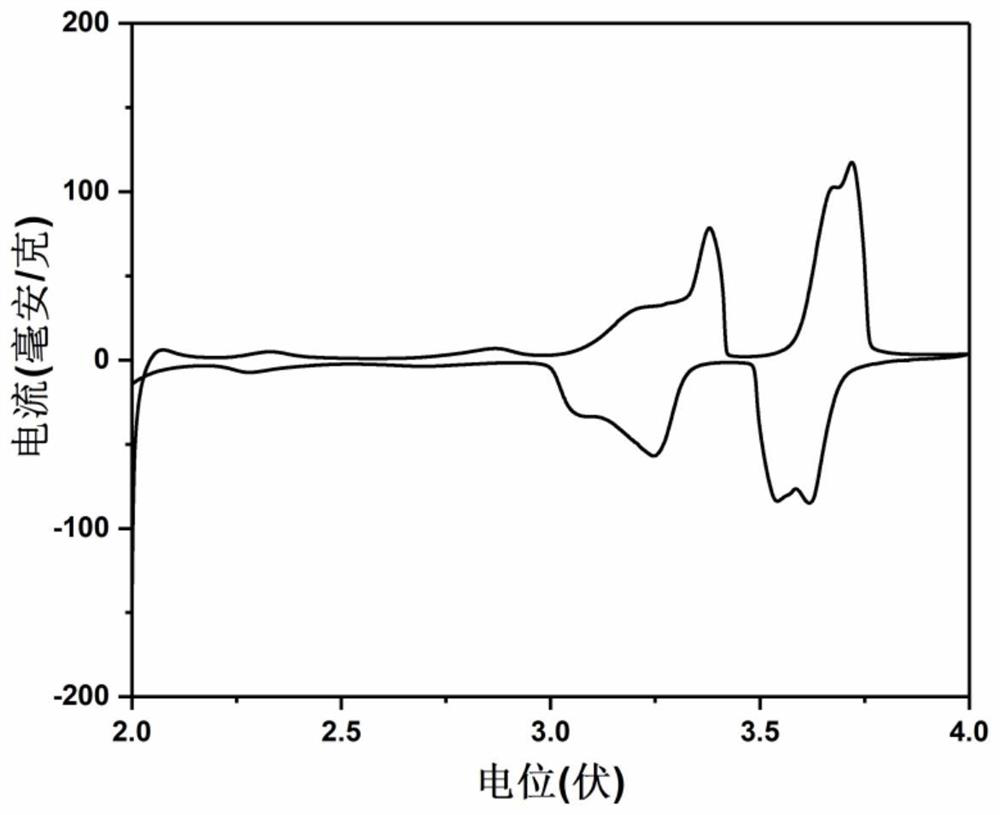

A technology for sodium-ion batteries and cathode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the inconsistency in the proportion of precursor metals and feed ratios, the difficulty of controllable preparation of target products, and the limited high-current cycling capability of materials, etc. problems, to achieve the effect of easy control of the feeding ratio, enhanced dynamic characteristics, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

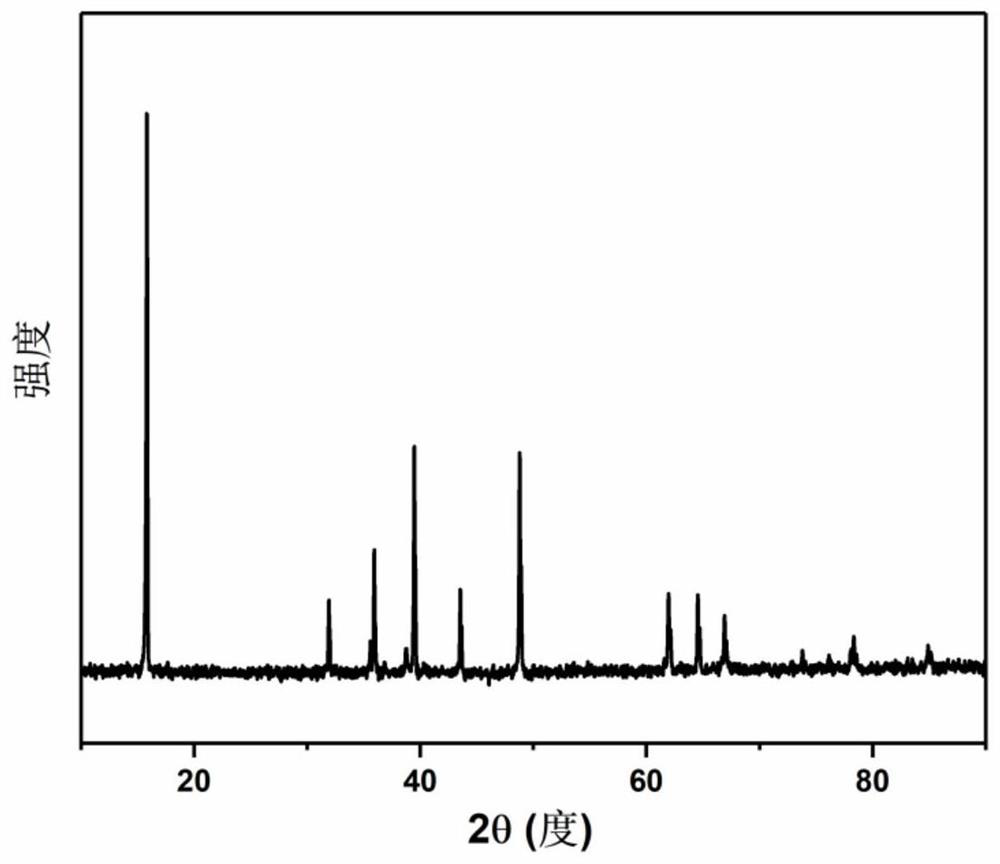

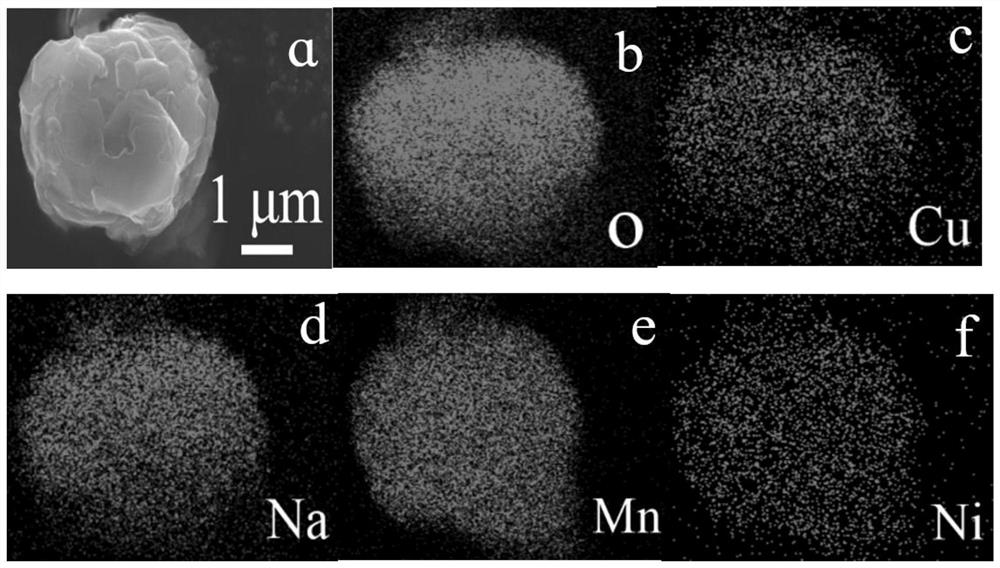

[0036] A preparation method of a spherical sodium ion battery positive electrode material, comprising the steps of:

[0037] (1) Prepare spherical MnCO by co-precipitation method with ammonium bicarbonate and manganese sulfate in ethanol and water 3 powder;

[0038] a. Ultrasonic dissolve ammonium bicarbonate and manganese sulfate in deionized water respectively to obtain concentrations of 0.1-0.3mol L -1 , 0.01~0.03mol L -1 clear solution of

[0039] b. Add equal volumes of ammonium bicarbonate clarified solution and manganese sulfate clarified solution into equal volume ethanol respectively, the substance ratio of said ammonium bicarbonate and manganese sulfate is 10~30:1, mix the solution at room temperature After stirring for 3 hours, a milky white suspension was obtained;

[0040] c. Let the milky white suspension stand, pour off the supernatant, put it into a centrifuge for centrifugation, then use water and ethanol to disperse, centrifuge, and wash in turn to obtain...

Embodiment 1

[0047] Weigh 0.0014mol of ammonium bicarbonate and 0.014mol of manganese sulfate and dissolve them in 140mL deionized water beakers, respectively, ultrasonically for 1 minute, so that the raw materials are completely dissolved and mixed evenly to obtain a clear solution, and then added to the beaker containing 14mL of ethanol in turn, Stir for 3 hours, make it fully mixed, let it stand for 20 minutes, pour off the supernatant, then centrifuge at 8000 rpm for 5 minutes, then wash with deionized water and ethanol once respectively, and then put in Dry in an oven at 80°C for 1 hour to obtain light yellow spherical MnCO 3 powder, light yellow spherical MnCO 3 Put the powder in a clean small magnetic boat. After the muffle furnace rises to 400°C with a power of 100W, place the small magnetic boat in the middle of the muffle furnace and keep it for 5 hours. When the holding time is reached, quickly remove the small magnetic boat from Take it out from the muffle furnace and make it ...

Embodiment 2

[0053]Weigh 0.042mmol of ammonium bicarbonate and 0.0014mmol of manganese sulfate and dissolve them in 140mL deionized water beakers, respectively, ultrasonically for 1 minute to completely dissolve the raw materials and mix them uniformly to obtain a clear solution, then add them to the beakers containing 14mL of ethanol in turn, Mix the two solutions evenly, stir for 3 hours, make them fully mixed, let stand for 20 minutes, pour off the supernatant, then centrifuge at 8000 rpm for 5 minutes, then wash with deionized water and ethanol in turn. 1 time, and then dried in an oven at 80°C for 1 hour to obtain light yellow spherical MnCO 3 powder, light yellow spherical MnCO 3 Put the powder in a clean small magnetic boat. After the muffle furnace rises to 350°C with a power of 100W, place the small magnetic boat in the middle of the muffle furnace and keep it for 5 hours. When the holding time is reached, quickly remove the small magnetic boat from Take it out of the muffle furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com