A vacuum fryer in which steam pressure moves ingredients to be heated evenly

A vacuum fryer and uniform heating technology, applied in the direction of roaster/barbecue grid, kitchen utensils, household utensils, etc., can solve the problems of food nutrient damage, food quality difference, food material temperature unevenness, etc., to achieve greater The effect of power and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

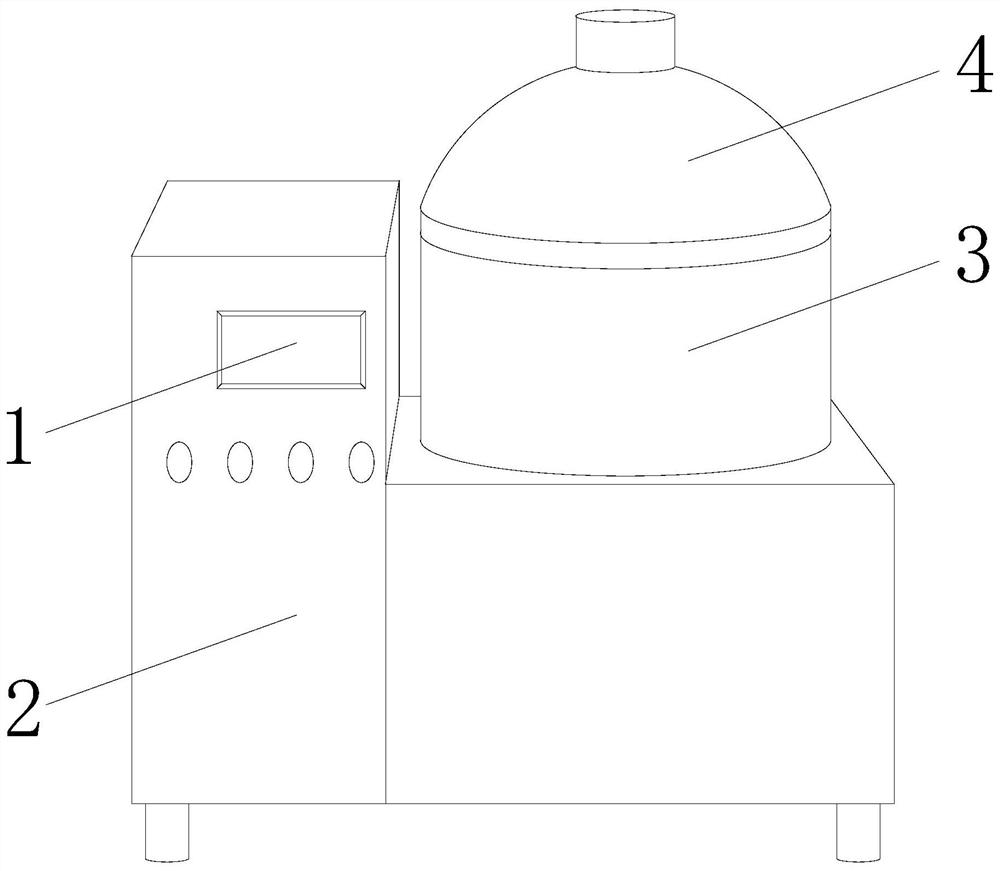

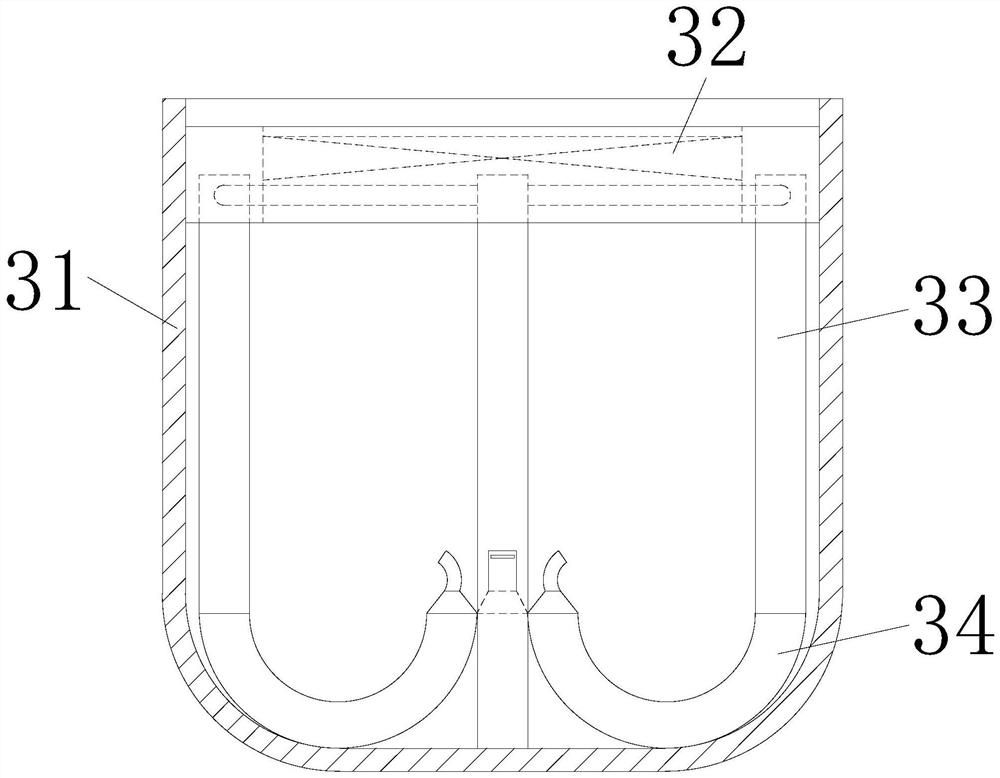

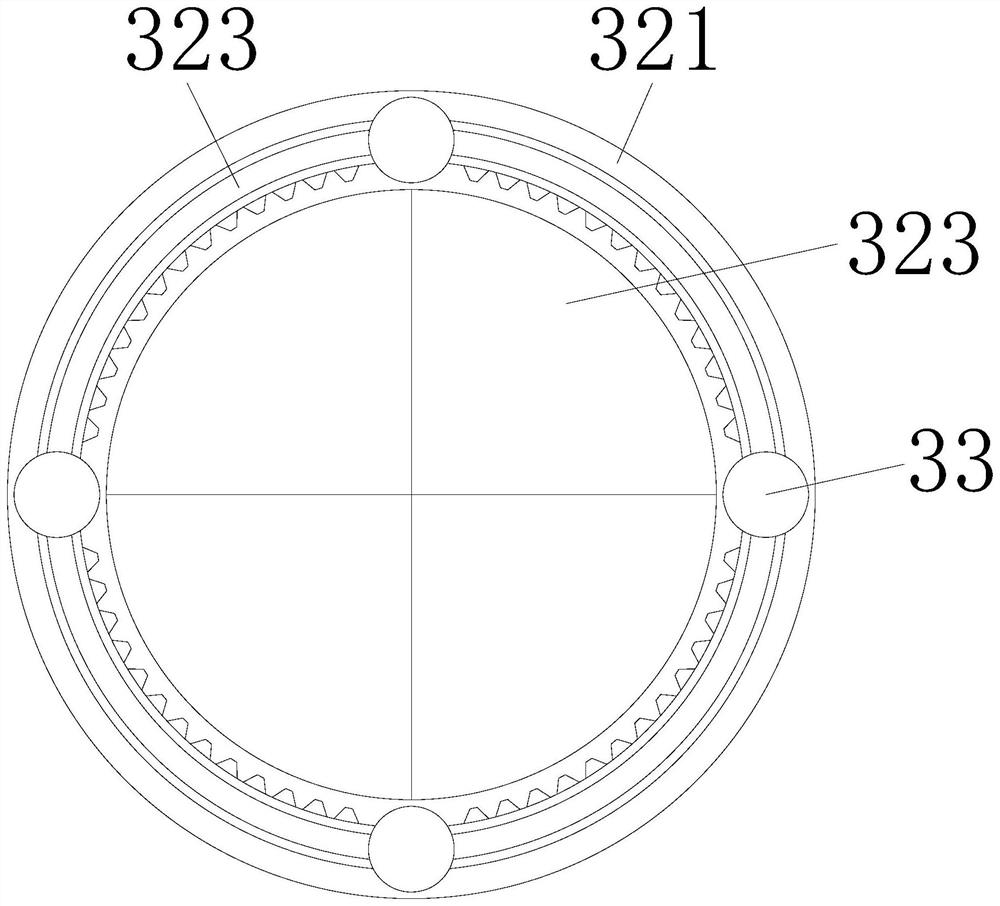

[0022] see Figure 1-Figure 9 , the present invention is a vacuum fryer in which steam pressure stirs ingredients to be evenly heated. Its structure includes a display panel 1, a steam heater 2, a steam pressure vacuum fryer 3, and a vacuum pot cover 4. The front surface of the steam heating machine 2 is electrically connected by wires. The steam heating machine 2 is installed inside the right end of the steam pressure vacuum fryer 3, and a vacuum pot cover 4 is installed on the top of the steam pressure vacuum fryer 3. The pressure vacuum fryer 3 includes a stainless steel shell 31, a peak steam pressure collector 32, a steam pressure compression tube 33, and a pan bottom airflow injection mechanism 34. The bottom end of the stainless steel shell 31 is installed inside the steam heater 2, and the peak steam The pressure collector 32 is fixedly installed on the inner top of the stainless steel shell 31, and the top of the steam pressure compression tube 33 is installed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com