Heterogeneous metal material pipeline welding device

A technology of dissimilar metals and welding devices, applied in welding equipment, metal processing equipment, high-frequency current welding equipment, etc., can solve the problems of expensive and complicated equipment, poor welding effect, etc., and achieve improved welding quality and faster heating rate , the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

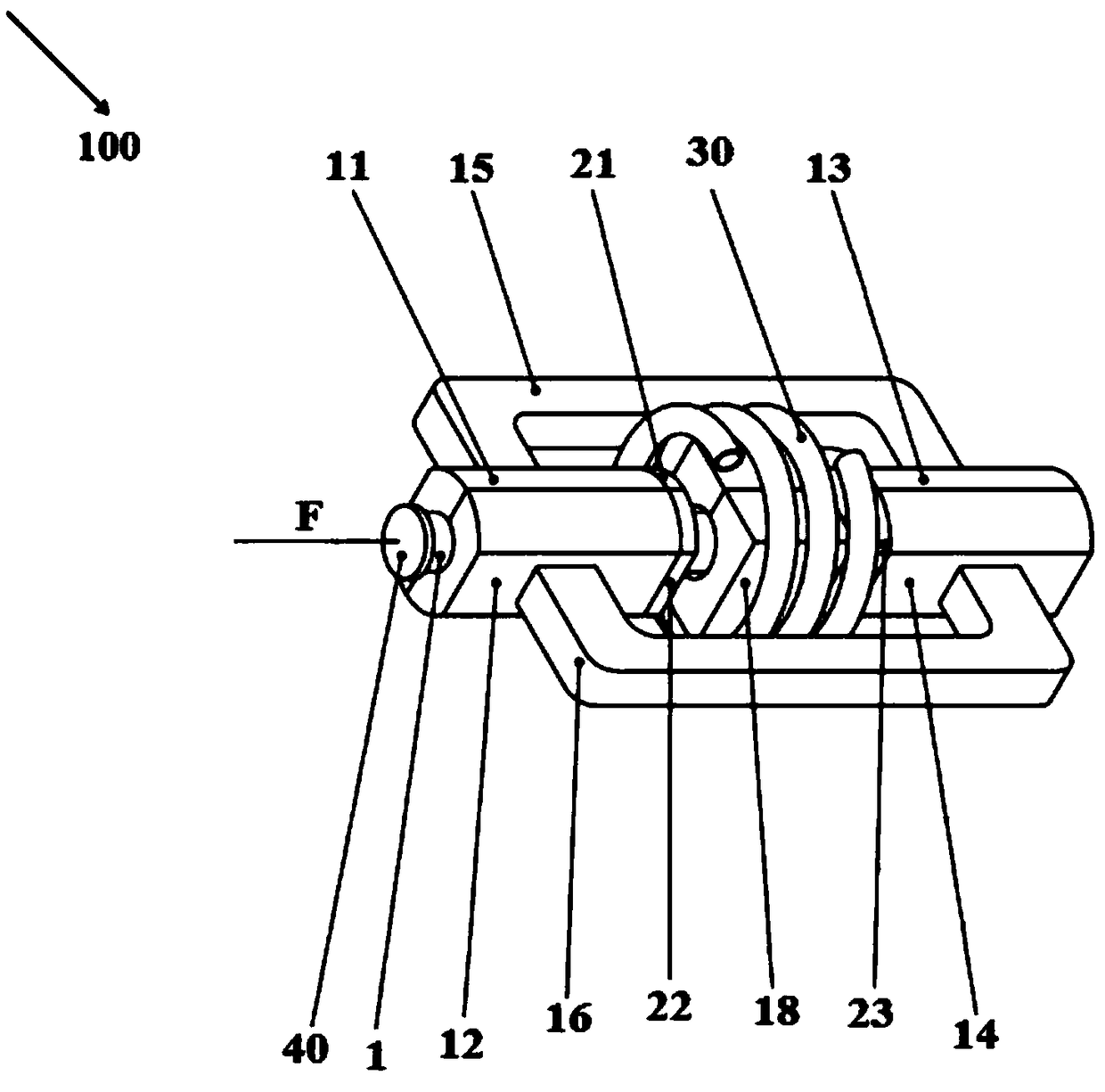

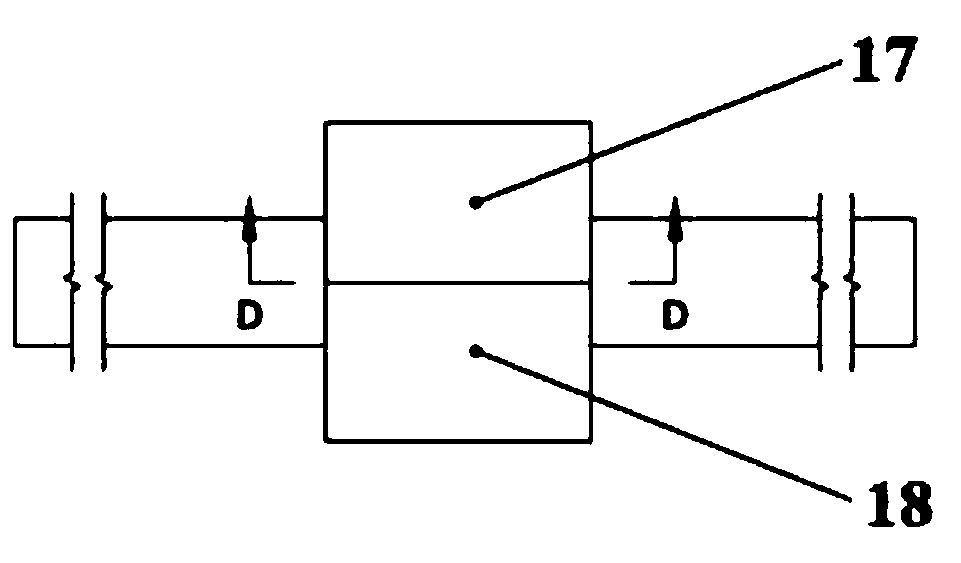

[0025] Such as Figure 1-Figure 4 As shown, a pipe welding device 100 of dissimilar metal materials in this embodiment is used for welding coaxial first pipe 1 and second pipe 2 of different metal materials, including: support sleeve assembly 10, heat insulation assembly 20 and high frequency induction heating coil 30.

[0026] The first pipe 1 is a copper pipe with a tapered front end, the second pipe 2 is an aluminum pipe, and the tapered portion of the first pipe 1 is inserted into the second pipe 2 .

[0027] A hydraulic cylinder (not shown in the figure) is connected to the tail end of the first pipe 1 for applying pressure F to the first pipe 1 .

[0028] The first pipe 1 passes through the upper support sleeve 11 of the first pipe, the lower support sleeve 12 of the first pipe, and a baffle plate 40 for making the stress on the first pipe 1 more uniform is arranged between the hydraulic push rod of the hydraulic cylinder.

[0029] A stopper (not shown in the figure) i...

Embodiment 2

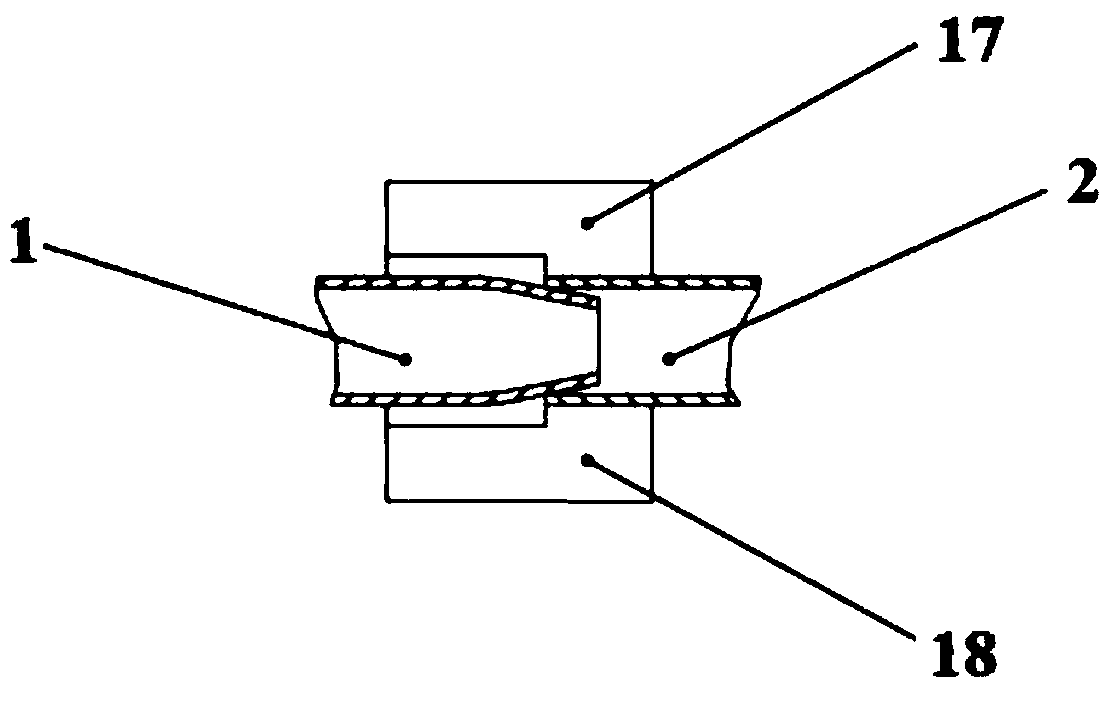

[0056] Such as Figure 5-Figure 6 As shown, this embodiment has a support sleeve assembly 10 , a heat insulation assembly 20 and a high-frequency induction heating coil 30 . Compared with Embodiment 1, the upper middle support sleeve 19 and the lower middle support sleeve 110 of this embodiment are different, having the following structure:

[0057] When the upper middle support sleeve 19 and the lower middle support sleeve 110 embrace the first pipe 1 and the second pipe 2 in the radial direction, there is a gap between the upper middle support sleeve 19 and the lower middle support sleeve 110 for discharging the copper-aluminum eutectic liquid .

[0058] Both the inner side of the upper middle support sleeve 19 and the inner side of the lower middle support sleeve 110 have a hole with the same radius as the outer radius of the first tube 1 at the coincidence place of the first tube 1 and the second tube 2 for discharging the eutectic liquid.

Embodiment 3

[0060] The structure of this embodiment is the same as that of Embodiment 1. There is a gap between the upper middle support sleeve 19 and the lower middle support sleeve 110 for discharging the copper-aluminum eutectic liquid, and the upper middle support sleeve 19 and the lower middle support sleeve respectively 110 is provided with grooves (not shown in the figure), two grooves are arranged on the left side of the junction of the first pipe 1 and the second pipe 2, and the groove on the upper middle support sleeve 19 is larger than that of the lower middle support sleeve 110 grooves are used to make the eutectic liquid flow out better when it flows upwards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com