Integrated multi-procedure treatment all-in-one machine for safety capacitor

A safety capacitor, multi-process technology, applied in the field of safety capacitor processing equipment, can solve the problems of high labor cost, damage to product performance, and easy packaging errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The technical solution of the present invention will be described in detail below in conjunction with the drawings.

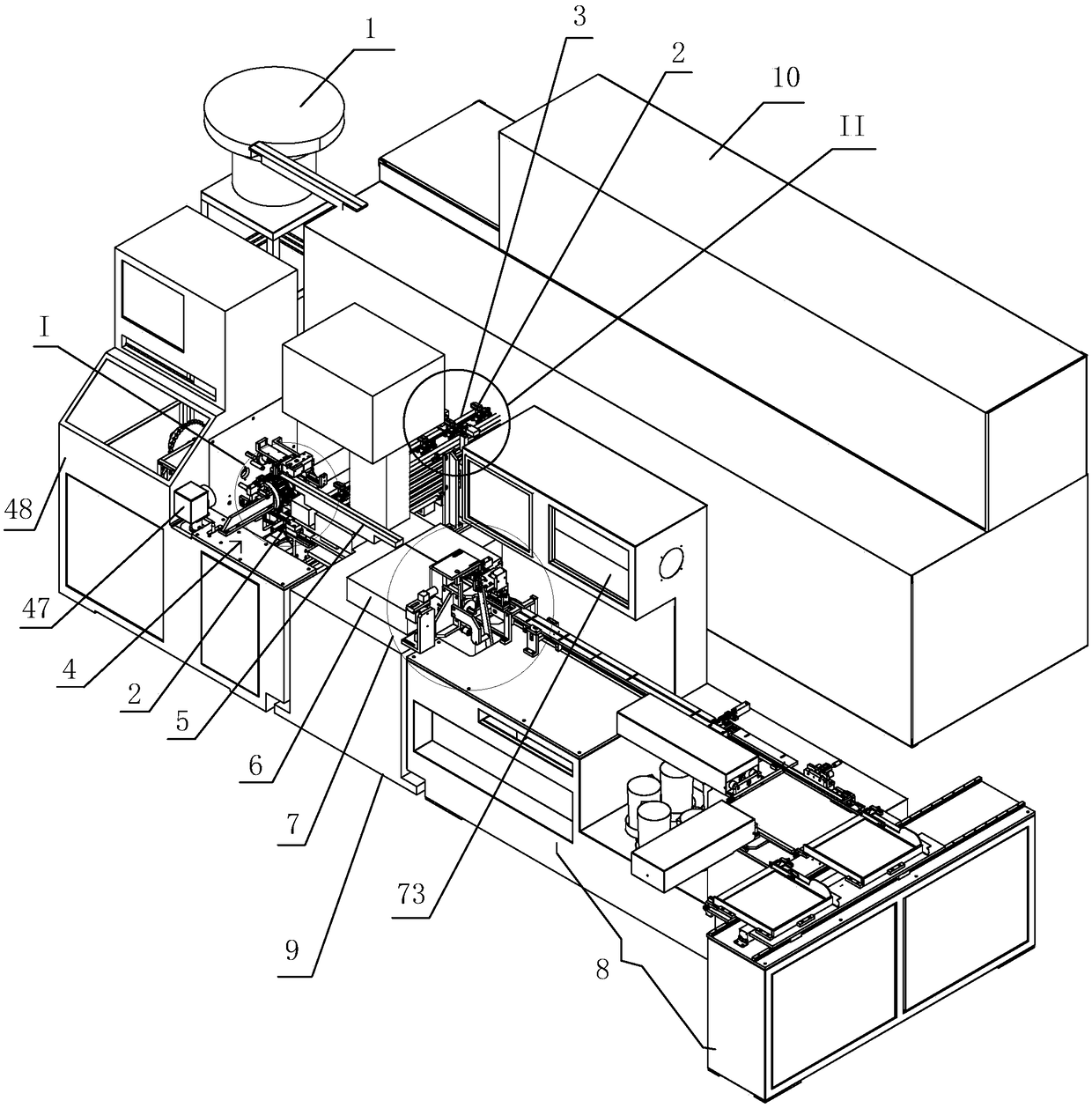

[0076] See figure 1 As shown, the integrated multi-process processing machine of the safety capacitor of this embodiment,

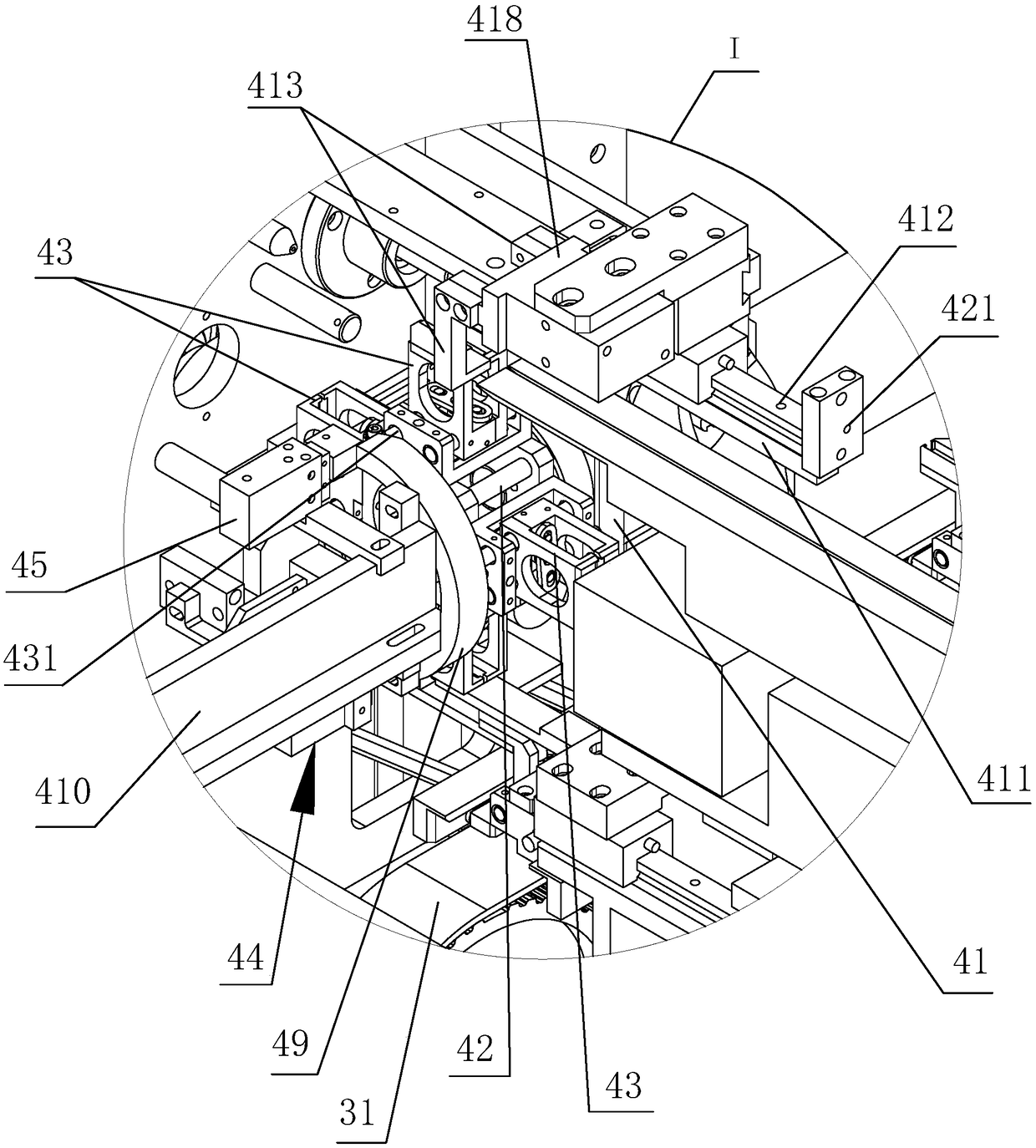

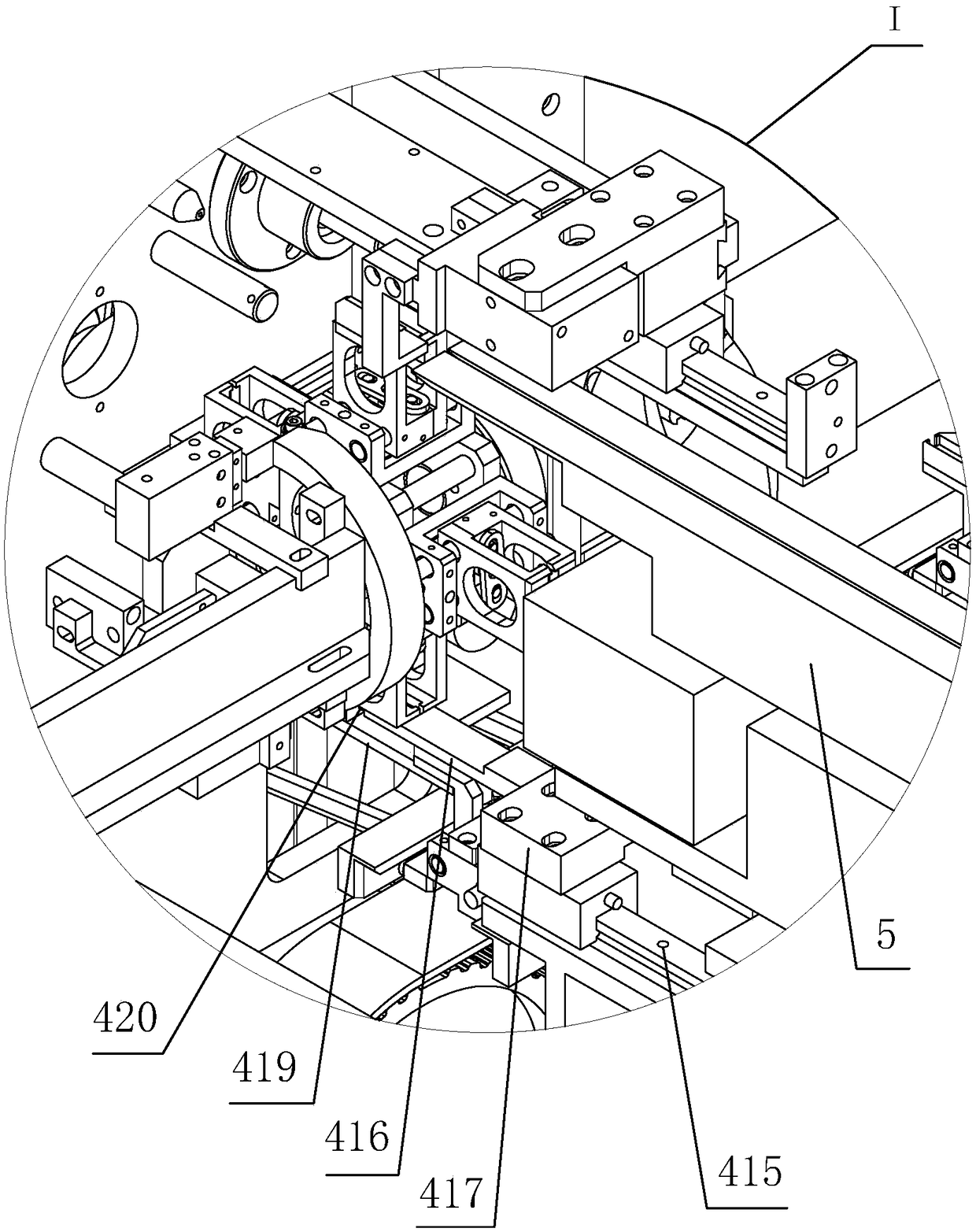

[0077] Comprising a working frame 9, said working frame 9 is provided with a vibrating plate feeding mechanism 1, an electrical performance testing mechanism 10 for performing electrical performance detection on materials sent out from the vibrating plate feeding mechanism 1, and an electrical performance testing mechanism 10 for performing electrical performance testing on materials sent from the vibrating plate feeding mechanism 1. 10, the grasping mechanism for clamping the material at the discharge end, multiple clamp mechanisms 2 for receiving the materials released by the grasping mechanism, and the clamps for sending the clamp mechanism 2 to the laser marking mechanism 4 directly below the feed end one by one Flat feeding me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com